Module 5 - Transportation Research Board

advertisement

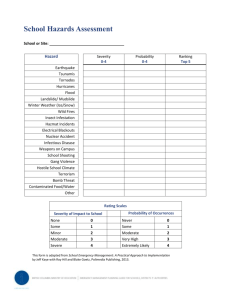

TOOLKIT FOR HAZARDOUS MATERIALS TRANSPORTATION EDUCATION 1 This work is sponsored by the U. S. Department of Transportation Pipeline and Hazardous Materials Safety Administration (PHMSA). It was conducted through the Hazardous Materials Cooperative Research Program (HMCRP), which is administered by the Transportation Research Board of the National Academies. Prepared by 3 Sigma Consultants, LLC 909 Edenbridge Way, Nashville, TN 37215 Module 5: Hazmat Risk Management 2 Learning Outcomes At the end of this module students will be able to: 1. Recognize some common types of hazmat transportation incidents 2. Identify root causes of typical hazmat transportation incidents 3. Define risk and key terms associated with risk management 4. List the steps involved in the risk management process 5. Evaluate the likelihood and consequences associated with hazmat transportation risk scenarios 3 Topics • • • • • Hazmat transportation case study examples Overview of hazmat transportation incident statistics Overview of risk management techniques Risk communication and management tools Risk management for hazmat transportation 4 Hazmat Transport Case Study 1: Rail • In 1979, in Mississauga, Ontario, a train consisting of 3 engines, a caboose and 106 cars derailed at a level crossing. In the wreckage were 11 cars of propane, 4 cars of caustic soda, 3 cars of styrene, and a car of chlorine. Not long after the derailment, a massive propane explosion occurred, followed by two other propane explosions within 25 minutes. • Approximately 217,000 people were evacuated from the area including a hospital due to concerns about the chlorine gas. Watch the video: http://www.youtube.com/watch?v=hEi2Do9tNPI 5 What went wrong? Could it have been prevented? • Heat began to build up in an improperly-lubricated bearing on one of the wheels on the 33rd car, resulting in the condition known among train workers as a "hot box". • The friction eventually burned through the axle and bearing, and a wheelset (one axle and pair of wheels) completely fell off causing the derailment. 6 Hazmat Transport Case Study 2: Highway • On the night of April 7, 1982, a drunk driver in the Caldecott Tunnel, CA, hit the tunnel wall and then pulled to the left lane to inspect the vehicle. • Moments later, a double tanker carrying gasoline hit the car causing gasoline to begin leaking into the gutters with small fires emerging around the tank and leaks. The driver escaped the tunnel, but others continued to enter. The tunnel ventilation system remained off for the majority of the time. • Many drivers were able to back out of the tunnel, but four remained trapped. • Seven individuals died as a result of the accident : two in crashes, five by smoke inhalation and fire. Another two were treated for injuries at the hospital. 7 Hazmat Transport Case Study 3: Marine • John Bavaret, a licensed apprentice-mate aboard the M/V Mel Oliver, steered the towboat without a properly-licensed captain present from approximately July 20, 2008 through July 23, 2008. During this time, at 1:30 A.M. on July 23, 2008, the M/V Mel Oliver collided with the M/V Tintomara, a 600-foot tanker ship, causing the release of approximately 282,828 gallons of fuel oil in the lower Mississippi River near downtown New Orleans. . • All four crewmembers were safely rescued from the water and the waterway was closed for six days to maritime traffic to facilitate the cleanup and salvage. • The event caused a ripple effect throughout the transportation system and delays to other industries. http://www.ecaptain.com/node/19 74 Watch the video and read more: http://gcaptain.com/captain-mvoliver-sentenced/ 8 Hazmat Transport Case Study 4: Pipeline • An electrical problem triggered an explosion at a PG&E Gas control center in Milpitas, California, causing valves that regulate pipeline pressure to open, allowing more gas into the line. • As the pressure built up, inadequate welds in a section of pipe ruptured, allowing 47 million cubic feet of gas to escape in a huge pillar of fire. • This series of events led to a gas pipeline explosion in September of 2010 that killed eight people and destroyed 38 homes in the Bay Area. 9 Hazmat Transport Case Study 5: Air • ValuJet Flight 592 was a domestic passenger flight carrying chemical oxygen generators from SabreTech that had not been properly packaged in the cargo compartment. The firing pins of the generators activated (likely by accident) causing heat and fire in the cargo area. • The NTSB investigation found that SabreTech workers had improperly prepared the canisters for travel and incorrectly indicated on the cargo manifest that the canisters were “expired”, leading handlers to consider them empty when they were not. • The fire in the cargo area led to electrical problems, the crew and passengers lost consciousness from the toxic fumes. • The flight crashed at 500 mph in the Florida Everglades killing all 110 individuals on board. Photo from: http://www.google.com/imgres?q=valujet+flight+592&hl=en&c lient=firefox-a&hs=Mhv&sa=X&tbo=d&rls=org.mozilla:enUS:official&biw=1440&bih=730&tbm=isch&tbnid=QM0gvGPcV QlXpM:&imgrefurl=http://www.abovetopsecret.com/forum/thr ead463089/pg&docid=e1VGAdW-NYRPM&imgurl=http://files.abovetopsecret.com/images/mem ber/facc30ac9fca.jpg&w=600&h=426&ei=IyWcUKSSE5Si8ASUi4 DgAw&zoom=1&iact=hc&vpx=341&vpy=411&dur=1401&hovh= 189&hovw=267&tx=149&ty=124&sig=10313427039333015287 7&page=1&tbnh=140&tbnw=200&start=0&ndsp=28&ved=1t:42 9,r:16,s:0,i:136 http://www.google.com/imgres?q=ValuJet+Flight+592&hl=en&client=firefoxa&hs=Oki&sa=X&tbo=d&rls=org.mozilla:enUS:official&biw=1440&bih=730&tbm=isch&tbnid=V-PW39XYbY0dM:&imgrefurl=http://www.abovetopsecret.com/forum/thread268715/pg 1&docid=Xd03Ycr7lh03WM&imgurl=http://i160.photobucket.com/albums/t197 /nick7261/valuejetdebrisfield.jpg&w=626&h=469&ei=nJnsUMi1FIaZ0QHkjoHAA Q&zoom=1&iact=hc&vpx=1140&vpy=62&dur=1284&hovh=194&hovw=259&tx= 204&ty=86&sig=103134270393330152877&page=1&tbnh=145&tbnw=164&star t=0&ndsp=29&ved=1t:429,r:14,s:0,i:146 10 Watch the video: http://www.youtube.com/watch?v=wkmr1V5smKA Incident vs. Accident • Accident – used to describe things that happen unintentionally • Incident - has a wider meaning and can be used both for accidents and for intentional actions such as crimes. Note: Accidents are counted as a subset of incidents. 11 Case Study Discussion • Are there any distinguishable trends among the case studies presented? – Causes – Consequences • Would any be defined as accidents? • How frequently do you think these types of events occur? – Large-scale releases – Small-scale releases • Can you identify some potential causes of hazmat transportation incidents? 12 Hazmat Incident Occurrences • Many incidents occur each year in all modes of transportation with varying degrees of severity • Many are minor and do not make headlines Source: PHMSA 13 Hazardous Materials Transportation Incidents: 1980-2010 1Water category only includes packaged (nonbulk) marine. Non-packaged (bulk) marine hazardous materials incidents are reported to the U.S. Coast Guard and are not included. 2Other category includes freight forwarders and modes not otherwise specified. NA = not available; R = revised Source: US D.O.T. FHWA (http://ops.fhwa.dot.gov/freight/freight_analysis/nat_freight_stats/docs/11factsfigures/table5_4hist.htm) 14 Potential Impacts of a Hazmat Release • Human health – – – – – – – Acute fatality/injury Reproductive failure and birth defect Cancer Impaired immune system Respiratory illness Cardiovascular disease Effects of contaminated drinking water • Environment – – – – – – Crop and vegetation destruction Damage to fish/birds/mammals and their habitats Endangered species and loss of plant/animal diversity Soil degradation Disruption of food chain Water contamination *Impact severity will depend on the duration and rate of exposure (dose) and the manner in which the recipient reacts when subjected to that dose (response). 15 Hazardous Materials Transportation Incidents, Injuries and Fatalities: 2009 • Less than 10% of large truck shipments include hazmat as all or part of the cargo load. • In contrast, less than 5% of large truck accidents involve trucks carrying hazmat. Source: FMCSA 16 2011 Hazmat Incidents and Fatalities by State Number of Incidents Number of Incidents with Fatalities Source: PHMSA 17 Hazardous Materials Transportation Incidents by Mode, 1985-2009 Source: PHMSA 18 2011 Hazmat Incidents by Hazard Class Source: PHMSA 19 2011 Hazmat Incidents by Material Type Material Percent of Total Flammable-combustible liquid 48.9 Corrosive material 24.8 Combustible liquid 6.7 Non-flammable compressed gas 3.6 Oxidizer 3.5 Flammable gas 2.2 Poisonous material 2.2 Other 8.1 Source: PHMSA 20 Hazmat Incidents by Transport Phase Source: PHMSA 21 Hazardous Materials Transportation Incidents: 1980-2010 Source: US D.O.T. FHA (http://ops.fhwa.dot.gov/freight/freight_analysis/nat_freight_stats/docs/11factsfigures/table5_4hist.htm) 22 Consider These Numbers for 2011… • 32,367 people lost their lives on America’s roadways in motor vehicle crashes • 8,302 train accidents occurred • 26 people were killed by lightning strikes • 12 people were killed by shark attacks • 5 people died as a result of hazmat incidents 23 Total Annual and Normalized Risk Associated with Transportation Incidents Source: HMCRP Report 9 24 Increasing Number of Occurrences Incident Severity Pyramid Major Injuries Minor Injuries Property Damage Incidents Near-Miss Incidents Substandard Act and Conditions 25 What are Risks and How do we Manage Them? • Risk - The potential for an unwanted outcome resulting from an incident as determined by its likelihood and the associated consequences. • Risk Management - A process for identifying, assessing and reducing risks to public safety and security, environmental quality and economic well-being or a method for prioritizing risk management needs and evaluating risk control strategies. 26 The Tradeoffs of Hazmat Transportation Example: Transport of a necessary hazmat commodity (e.g., chlorine gas) • Potential Risks: – Exposure of employees, public, and environment – Potential fines for improper handling and packaging – Potential incident • Company reputation • Clean-up and recovery costs • Loss of business • Rewards: – Income/profit – Limited competition – Good company reputation if job handled properly – For chlorine gas example, large population will have access to safe drinking water 27 Fundamental Questions of Risk Management • What can go wrong? • How likely is it? • What are the consequences? http://www.math.ucsb.edu/~atzberg/fall20 05/index_files/financialRisk.jpg • How can we use available resources to most effectively control undesirable risks? 28 Types of Risks Associated with Hazmat Transport • Operational – Failed procedures – Improper packaging • Information Systems – Improper tracking, marking or documentation • Environmental – Population/carrier/environmental exposure • Human Resource – Unqualified drivers/handlers • Security – Theft or malicious acts • Reputational – Bad corporate reputation – Loss of customers 29 Key Terms for Risk Management • Hazard – the inherent characteristic of a material, condition, or activity that has the potential to cause harm to people, property, or the environment • Risk – the combination of the likelihood and the consequence of a specified hazard being realized • Risk assessment – the systematic approach to organizing and analyzing scientific knowledge and information about potentially hazardous activities • Risk management – the systematic application of policies, practices, and resources to assessment and control of risk affecting human health and safety and the environment • Risk control point – a place or step within a given process where actions can be taken to reduce risk • Enterprise risk management – an approach that considers all potential hazards that may threaten an organization on a daily basis Source: http://phmsa.dot.gov/staticfiles/PHMSA/DownloadableFiles/Files/risk_framework.pdf 30 Increasing involvement and investment The Corporate Risk Pyramid – Varying Levels of RM (4) CompanySpecific Risk Management Activities (3) Company Policies (2) Industry Practices and Standards (1) Regulations 31 The Risk Pyramid Tiers 1 and 2: Regulations and Industry Practices • Regulations – At a bare minimum, companies are required to meet regulations to protect the public and environment. – Failure to do so may result in fines and adverse actions against the company (including decreased reputation). • Industry Practices and Standards – Some protocols have been adopted by industry sectors to go above and beyond the minimum regulations. – For example, carriers may choose to have dedicated drivers with certain qualifications for specific types of shipments. 32 Sample Regulations Associated with Hazmat Risk Management • Federal Motor Carrier Safety Administration (FMCSA) – Hazardous Materials Endorsement (HME) for commercial drivers to carry hazmat materials • Occupational Health and Safety Administration (OSHA) – Performs risk assessments to ensure safety of employees in the workplace – The risk associated with occupational exposure to a toxic substance at the current permissible exposure limit (PEL) must be quantified. If OSHA determines that there is significant risk to workers' health at its current standard, then it must quantify the risk associated with a variety of alternative standards to determine at what level, if any, occupational exposure to a substance no longer poses a significant risk. • Transportation Security Administration (TSA) – Hazardous Materials Endorsement Threat Assessment Program conducts a security threat assessment for any driver seeking to obtain, renew, or transfer a hazardous materials endorsement (HME) on a state-issued commercial drivers license (CDL) • Many more exist Source: TSA, OSHA, FMCASA 33 Industry Risk Management Protocols Used in Hazmat Transport • Responsible Care® – the chemical industry’s world-wide performance initiative. Its participating companies are industry leaders, bound together by a commitment to address challenges and continuously improve the performance of the chemical industry. • Responsible Care Management System (RCMS) - combines Responsible Care® with the practices of leading private-sector companies, the International Standards Organization and federal regulatory requirements • Responsible Distribution® – Responsible Distribution is a mandatory, third-party verified environmental, health, safety & security program established by the National Association of Chemical Distributors (NACD) that lets members demonstrate their commitment to continuous performance improvement in every phase of chemical storage, handling, transportation, and disposal. Source: American Chemistry Council, National Association of Chemical Distributers 34 Industry Risk Management Protocols Used in Hazmat Transport • ChemStewards® - The Synthetic Organic Chemical Manufacturer Association's (SOCMA) ChemStewards® management program is a stepwise system approach to managing environmental, health, safety and security (EHS&S) activities which is designed specifically to meet the needs of batch, custom and specialty chemical manufacturing facilities. It defines core principles and provides guidance that helps ensure compliance with legal and regulatory requirements. • American Waterways Operators’ (AWO) Responsible Carrier Program (RCP) - is not specific to hazardous materials; however, it is all encompassing for improving the safe transportation on the waterways. AWO members use the RCP as a guide in developing company-specific safety and environmental programs that are tailored to the unique operational environments found in the barge and towing industry. The program complements and builds upon existing government regulations, requiring company safety standards that exceed those required by federal law or regulation. Companies are required to obtain a third party audit by an AWO-certified auditor to verify compliance. Source: Society of Chemical Manufacturers and Affiliates, The American Waterways Operators 35 Responsible Care© Management System (RCMS) • PLAN – Identify and evaluate potential hazards and risks associated with their products, processes, distribution and other operations (establish goals and objectives to address any significant hazards and risks, taking concerns of employees, communities, customers, suppliers and other stakeholders into consideration) • DO – Implement the plan. Establish, document and communicate responsibilities to meet stated goals and objectives, including processes to identify and meet staff training needs. • CHECK – Assess the progress. Companies measure and evaluate their performance, including compliance with regulatory and legislative requirements, and take corrective and preventive action to make necessary adjustments to the management system. Companies also establish procedures for identifying and maintaining Responsible Care records. • ACT - Senior management periodically reviews the adequacy and effectiveness of the management system and makes any changes necessary to enhance performance. The results of this process are shared with the company’s stakeholders. 36 Source: American Chemistry Council The Risk Pyramid Tiers 3 and 4: Company-specific Risk Management • Company Policies and Company-Specific Risk Management Activities – Some companies go above and beyond the industry practices to be “risk aware” or “risk averse” by investigating their potential exposure to risks and implementing internal policies to limit or reduce these risks – This often requires significant investment by the corporate leadership to perform the risk assessments and also implement policies – Sometimes third party consultants or auditors are hired to evaluate risks for an organization – Company size and resources may limit the ability of an organization to perform this higher level of risk management • Major corporate decisions may require a higher level of risk management (regardless of company size) – Siting of new facility, fleet modifications, etc. 37 Risk Management – An Enterprise-Wide Approach • Enterprise Risk Management allows you to – Identify all potential hazards – Assess the severity (frequency and consequences) – Evaluate mitigation options to reduce risk • Having a “risk aware” organization provides foresight and potential reduction in those events that could lead to major losses. 38 Managing Risks Related to Hazmat Transport • Attempt to predict, prevent, or plan for incidents to lessen their impacts – Evaluate routes – Modes of shipments – Containers used • The Risk Management (RM) Process – – – – Identify Analyze Assess/Evaluate Treat/Control (Mitigate or Reduce) (Source: EPCB Risk Management Consultants) 39 PHMSA’s Stepwise Approach to Risk Management for Hazardous Materials Transport Source: http://phmsa.dot.gov/staticfiles/PHMSA/DownloadableFiles/Files/risk_framework.pdf 40 The RM Process: Step 1 - Risk Identification • What could go wrong? – – – – – – Natural hazards Chemical spills Transportation accident Equipment failures Human error Others? • How do we plan for the future/unknown events? – Look at history and statistics – Consider future demands and projections – Combination of small events leading to a larger event (e.g., BP Horizon Oil Spill) – “Black Swan” events 41 What Could (or has) Gone Wrong - Root Cause Investigation of Incidents – To recognize the unsafe acts and/or conditions that caused the incident. – To identify the management system that failed to prevent it from happening. – To recommend remedial actions that will prevent it from happening again. • Performing root cause investigations – Work backward toward source of failure Root Cause Model Top Event (Result) Question Progression • Why investigate past incidents? Physical Roots (Why it happened?) Latent Roots (Management System Issues) 42 Hazmat Transport Risk Factors • Vehicle – Configuration, weight • Operator – Age, experience, condition, training, valid license • Packaging – Type, age, protection • Infrastructure and equipment – Type, condition, use • Situational – Speed, weather, lighting, time-of-day, maneuvering, impact location Source: Battelle, Hazardous Materials Transportation Incident Data for Root Cause Analysis, HMCRP Report 1 43 The RM Process: Step 2 – Analyze Risk Options For each event identified, consider both the likelihood or chance that it could happen and the potential consequences if that event were to occur Likelihood • The potential frequency or chance of occurrence – Transport mode – Material type – Shipment volumes – bulk or otherwise Consequences • • • • • • • Property damage Environmental damage Product loss Emergency response Evacuation/ disruption Transportation system impacts Others/intangibles 44 Hazmat Incident Data for Use in Risk Analysis – Historical Frequency and Consequences • U.S. DOT – PHMSA (provides statistical data on hazmat incidents, fatalities, causes, etc.) – FHWA – NTSB • Environmental Protection Agency – Maintains record of hazmat spills throughout U.S. • U.S. Coast Guard • Others… 45 Hazmat Transportation Incident Consequences Category Description Injuries and fatalities Transportation workers, incident responders, general public; direct and indirect (e.g., stress, secondary crashes) Property damage Damage to vehicles (carriers and others), transportation infrastructure, utilities, neighborhoods, businesses, public facilities Environmental damage Air, ground and/or water contamination with immediate or extended impacts on human health, flora, and/or fauna Product loss Loss of the material/product being transported Emergency response Costs to emergency responders and, for major events, other state and federal agencies, NGOs, and private sector responders Evacuation/ disruption Costs to people displaced from homes, schools, businesses; interference with normal community activities; loss of business and earnings; potential for regional economic impacts Transportation system impacts Costs for lost time, missed schedules, wasted resources, increased operating costs for transportation system users Cleanup Costs of decontamination; removal of absorbed material, damaged equipment, and other debris; disposal Intangibles Loss of credibility with investors, customers, partners, regulators, employees, media, and others 46 Common Risk Analysis Methods • Scenario Analysis – What ifs? – Evaluate all possible situations and outcomes – Scenario or event tree – Probabilistic analysis – Monte Carlo simulation Outcome 1.1 60% likely Outcome 1.2 30% likely Outcome 1 30% likely Risk B $20,000 implication • Internal Audit/Expert Panel – Use checklists or guides for evaluation – Provides expert/insider look at what may go wrong • External Audit/Third-Party Risk Consulting – Assists with entire RM process – Performs combination of risk audit, quantification, cost analysis, and reporting of results Risk A $100,000 implication Outcome 1.3 10% likely Outcome 2 70% likely Sample Risk Event Tree 47 Example Scenario Analysis Process – What can go wrong? • Assign frequency of scenario occurrence • Determine impacts of each scenario – What are the consequences? • Use likelihood and consequence estimates to assess scenario risks Rate hazards Rate exposure Rank risks Risk Analysis – How likely is it? Risk Screening • Develop scenarios of reasonably foreseeable events Inventory hazard scenarios Estimate event likelihood & consequence Identify risk reduction strategies Interpretation of risk analysis results Strategies recommended for implementation 48 Qualitative vs. Quantitative Risk Analysis Qualitative • Provides fast, cost-effective first-generation approach to risk analysis • Uses subjective judgment or simplified formulas to generate relative risk values • Can identify situations requiring more quantitative (absolute) risk analysis • Establishes benchmark of current risk status for evaluating effectiveness of risk reduction strategies Quantitative • Can be robust and involved process • Requires data/knowledge of frequency and potential consequences of events • Performed using statistical or simulation methods including event or fault trees, scenario analysis, or physical modeling • Provides absolute or relative risk analysis 49 Quantitative Analysis - Sample Event Tree 50 Quantitative Analysis - Sample Fault Tree 51 Use of Models for Toxic Release Quantitative Risk Analysis • Models can be used to determine the extent of a release and concentration to identify the impacted area and potential consequences • A few example models: – ALOHA, CAMEO, MARPLOT – air dispersion – CEQUAL-W2 – riverine dispersion of chemicals Hazardous Materials Release Discharge and Dispersion Models Flammable Release Explosion & Fire Models Toxic Release Effects Models Mitigation Factors Risk Calculation 52 The RM Process: Step 3 – Assess/Evaluate Risks • There are difficulties in comparing different types of risks – Property, assets, etc. ($) – Human lives (?) • Risk-cost – Allows for comparison of risks – Assigns dollar values for fatalities and injuries – Based upon national standards, medical bills, and claims data 53 Consequences Risk Heat Map – A Way to Rank and Prioritize Risks Very High High High Very High Very High High Medium Medium High Very High Medium Low Medium Medium High Low Low Low Medium High Low Medium High Very High Likelihood 54 Example Risk Heat Map – Route Evaluation Likelihood (per year) Routing Risk Options 4.5 4 3.5 3 2.5 2 1.5 1 0.5 0 $0.00 $50.00 $100.00 $150.00 $200.00 $250.00 $300.00 $350.00 Consequence per event (thousands of dollars) Scenario 1 Scenario 2 Scenario 3 Scenario 4 Note: Each scenario represents a different route for transport. 55 Class Exercise • In groups, fill in the provided Risk Heat Map with each of the five scenarios for route/transport options for the designated hazmat material • Which route/packaging option would you choose for transport of the hazmat material? Be prepared to present and explain your choice to the class. • Note: You may need to use online sources to estimate the severity of consequences should an incident occur. 56 Risk Appetite • Risk appetite is the type and degree of risk the company is prepared to accept. • The risk appetite may be a dollar amount that a company is willing to loose should an incident occur and may be indicated on the Risk Heat Map. • The risk appetite (or risk acceptance threshold) that defines the basis upon which enterprise risks are evaluated and treated. Depending on its appetite, an organization may choose to tolerate, avoid, control or transfer a particular risk. Any of these options may be considered risk treatment strategies. 57 The RM Process: Step 4 - Risk Treatment/Control • For risks chosen to be significant threats, one may wish to “treat” or “control” the risk • Choose strategies that remove or reduce risk by targeting likelihood and/or consequences Desired Treatment Strategies • Treatment options – – – – Accept Control/Mitigate Transfer Avoid 58 Risk Treatment/Control Options • A variety of activities are employed to control or reduce a range of risks • Everyday operations and planning for noncatastrophic risks – Training of employees • Proper packaging • Use of personal protective equipment (PPE)] • Proper handling of materials/packaging – Tracking of shipments – Following regulations and industry best practices • More severe or catastrophic risks – Hold or participate in drills or exercises to “play out” roles • Who’s responsible for what? • Incident command center operations 59 Tools for Hazmat Transport Risk Management – Evaluate Both Risks and Controls • Geographic Information System (GIS) analysis – Route analysis • Routes with high incident rates or dangerous driving conditions • Routes with heavy traffic volume or pass through densely populated areas (i.e., high exposure) • Routes near vulnerable areas (environmental or otherwise) – Modeling of spill impact areas • CAMEO and ALOHA (air dispersion) • COSIM (petroleum products spill model for marine systems) • And there are others… • Other Tools and Techniques – GPS Tracking of Shipments – PHMSA Risk Management SelfEvaluation Framework (RMSEF) (http://phmsa.dot.gov/hazmat/risk/rms ef) 60 Risk Reduction Strategies • Reduce likelihood of an incident occurring – Avoid routes with poor terrain or known hazards – Train employees on proper handling and packaging – Regularly inspect packages and vehicles/vessels • Reduce potential consequences if an incident occurs – Avoid routes that pass through highly populated or environmentally sensitive areas – Train employees to contain spills quickly – Have well documented emergency procedures – Proved PPE to employees to minimize exposure during leakage – Keep spill cleanup equipment on vehicles/vessels at all times 61 Communication as a Tool for Hazmat Risk Management • Risks are inerrant in everyday life • Awareness and proper communication of those risks can assist in both risk mitigation and consequence mitigation tool • Common tools used for communication of hazmat transport risks include the following: – Documentation – Signage/placards/markings – Common terminology used in training • • • • Marking Labeling Placarding Shipping documents 62 Risk Communication Roles and Responsibilities • Risk communication is necessary at various times in a hazmat shipment’s lifetime – Prior to an event – During an event (response) – Following an event (recovery) • Multiple stakeholders (audiences) are involved at each stage and require certain information – – – – – – Internal stakeholders Business partners (e.g., shippers, carriers, customers) Regulators Emergency responders Potentially impacted communities Media 63 Risk Communication Considerations • Safety – Provide information to public, transporters, and responders – Hazmat materials are used to make many of the products in our lives – Tradeoff: How much risk can be tolerated and still deliver the products where they need to be? – Example: Chlorine gas is used for drinking water treatment, but often must be transported through communities to get from the chemical plant to the water treatment facility. • Security – Some hazmat materials have potential to be used for intended harm (e.g., chlorine gas, explosives, etc.) – Signage and placarding may create targets for ill-willed individuals – Ranges from petty theft of shipments (batteries) to terrorist attack interest – Tradeoff: Ensuring safe transport and response through placarding and signage, but also identifying material properties to terrorists. 64 Additional Risk Communication Considerations • False Information – When an incident occurs, the information shared with the public and others by the media may be “glorified” to “sell a story” – The media plays a critical role in public awareness and understanding of hazmat transport • Perspectives – How much hazmat passing through your neighborhood is too much? – Risk perception may be that all hazmat transport is bad or “too risky”. However, decontamination of drinking water for the greater public may outweigh the dangers to a few of a possible chlorine spill. • BANANA – Build Absolutely Nothing Anywhere Near Anybody – Some feel that this should be the case – no hazmat anywhere – However, what would society be like if chemical plants and facilities using hazardous materials weren’t allowed. 65 Risk Management Limitations • As we now know, risks are inherent in our everyday lives. • Risk management (even at best) cannot prevent every incident from occurring or ensure that there are no adverse consequences associated with an event. • Some events are beyond your control (e.g., natural disasters). • In those cases, effective incident response can reduce the impacts and consequences. • Evaluating previous incidents can help us in managing the risks of future events (e.g., develop new/better regulations, improved packaging, etc.). 66 Regulations Resulting from Historic Incidents • Historic incidents have led to increased and improved regulations of many hazmat materials and their transport processes • Regulations are developed based upon an understanding of the root cause failures that led to an incident’s occurrence • Examples: – – – – Amoco Cadiz Oil Spill (1978) – Port and Tanker Safety Act Love Canal, NY (1979) – CERCLA (Superfund) Times Beach, MO (1982) dioxin incident – EPCRA (SARA Title III) Mississauga, Ontario, Canada, railcar explosion (1979) – After-Action Analysis and Reports required – Exxon Valdez (1989) – Oil Pollution Act • While incidents still occur today, it is difficult to know how many have been prevented thanks to implemented regulations and improved risk management techniques Source: Claire B. Rubin & Associates, LLC – Disaster Timeline 67 RM Success Story: Trans-Alaska Pipeline • • • Proactively designed to provide a stable foundation and prevent accidents for a high-magnitude earthquake with a recurrence interval of 300-500 years even though at the time, no seismic criteria, codes, or standards existed for the area. In 2002, Alaska experienced magnitude-7.9 quake and 336 km rupture along the Denali Fault that resulted in damage to supports but none to pipeline itself. Therefore, there was no release of crude oil or threat to safety or the environment 68 RM Success Story: SS Santa Clara I • • • On January 4, 1992, Santa Clara I, a 479-foot long, 9593-gross-ton container ship, departed from left Port Elizabeth under a weather forecast with severe storm warnings. During the worst turbulence, the ship lost 21 containers including four containing arsenic trioxide. A three-phase response plan was developed: – – – • Phase I - initial sub-surface search to locate probable locations of the containers along the Santa Clara I’s path Phase II - positive identification of containers by remotely operated vehicles (ROVs) with video cameras Phase III – recovery and salvage of the containers including packing and transporting the arsenic trioxide to a facility capable of appropriate disposal The response to the incident was considered a success. – – New innovative techniques and imaginative combinations of technology proved to be the ultimate answer to a difficult, dangerous and expensive recovery operation. Methodical and scientific actions exceeded the “normal” requirements associated with a CERCLA response activity, with multiple agencies working together to prevent any possible environmental impact. 69 Key Takeaways • Hazmat transportation events occur that put people, property, and the environment at risk, but often the benefits outweigh the risks. • Most incidents are minor. • Risk management can be used to minimize the impacts of these incidents. • Even at best, risk management cannot prevent every incident. • Risk management includes identification, analysis, evaluation, and treatment. • Risk analysis can be either qualitative or quantitative. • Multiple tools and programs exist that can assist with risk management efforts. • Communication is a critical component of successful risk management. 70 Student Exercises • Incident statistics investigation: – Using the PHMSA website and reports on incidents, generate reports for the following: • The number of incidents for your home state per year by mode. • The top two causes of incidents for each mode for your home state in 2011. • Case study evaluation: – Choose two of the three case studies presented. – Perform additional investigation into the causes and outcomes of each event. – For each event, use the PHMSA website and incident statistics to determine the likelihood in a given year for such an incident type to occur and the average consequences ($ as determined by PHMSA). Plot these on a Risk Heat Map to determine which would be higher concern if you were a hazmat transportation manager. – Write a one page paper comparing and contrasting the events and what could have been done (if anything) to reduce the likelihood and/or consequences associated with each event. 71 Resources for Support and Additional Learning • PHMSA Incident Statistics (http://www.phmsa.dot.gov/resources/data-stats) • PHMSA Risk Management Self-Evaluation Framework (http://phmsa.dot.gov/hazmat/risk/rmsef) • Responsible Care (http://responsiblecare.americanchemistry.com/Respons ible-Care-Program-Elements/Management-System-andCertification/default.aspx) • HMCRP Report 1 - Hazardous Materials Transportation Incident Data for Root Cause Analysis (http://onlinepubs.trb.org/onlinepubs/hmcrp/hmcrp_rpt _001.pdf) 72