Strain - CSU, Chico

advertisement

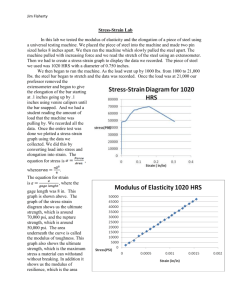

CM 197 Mechanics of Materials Chap 11: Mechanical Properties of Materials Professor Joe Greene CSU, CHICO Reference: Statics and Strength of Materials, 2nd ed., Fa-Hwa Cheng, Glencoe/McGraw Hill, Westerville, OH (1997) CM 197 1 Chap 11: Mechanical Properties • Objectives – – – – – – – – Introduction Tension Test Stress-Strain Mechanical Properties of Materials Compression Test Allowable Stresses and Factor of Safety Stress Concentration Elastic Design Versus Plastic Design 2 Allowable Axial Load • Structural members are usually designed for a limited stress level called allowable stress, which is the max stress that the material can handle. – Equation 9-1 • Required Area P A can be rewritten Pallow allow A – The required minimum cross-sectional area A that a structural member needs to support the allowable stress is from Equation 9-1 Pallow – Eqn 9-3 A – Example 9-1 allow – Example 9-2 • Internal Axial Force Diagram – Variation of internal axial force along the length of a member can be detected by this – The ordinate at any section of a member is equal to the value of the internal axial force of that section – Example 9-3 and 9-4 – Statics review 3 Strain • Strain: Physical change in the dimensions of a specimen that results from applying a load to the test specimen. • Strain calculated by the ratio of the change in length, , and the original length, L. (Deformation) ( Lf L ) L L L • Where, – – – – = linear strain ( is Greek for epsilon) = total axial deformation (elongation of contraction) = Lfinal –Linitial = Lf - L L = Original length Strain units (Dimensionless) • Units – When units are given they usually are in/in or mm/mm. (Change in dimension divided by original length) • % Elongation = strain x 100% 4 Strain • Example – Tensile Bar is 10in x 1in x 0.1in is mounted vertically in test machine. The bar supports 100 lbs. What is the strain that is developed if the bar grows to 10.2in? What is % Elongation? • =Strain = (Lf - L0)/L0 = (10.2 -10)/(10) = 0.02 in/in 0.1 in 1 in 10in 100 lbs • Percent Elongation = 0.02 * 100 = 2% • What is the strain if the bar grows to 10.5 inches? • What is the percent elongation? 5 Stress-Strain Diagrams Forces • Equipment – Tensile Testing machine • UTM- Universal testing machine • Measures Test Sample – Load, pounds force or N – Deflection, inches or mm • Data is recorded at several readings – Results are averaged – e.g., 10 samples per second during the test. • Calculates – Stress, Normal stress or shear stress – Strain, Linear strain – Modulus, ratio of stress/strain Fixed 6 Modulus and Strength • Modulus: Slope of the stress-strain curve – Can be Initial Modulus, Tangent Modulus or Secant Modulus • Secant Modulus is most common Ultimate Strength Modulus • Strength – Yield Strength Stress • Stress that the material starts to yield Yield Strength • Maximum allowable stress – Proportional Limit Proportional Limit Strain • Similar to yield strength and is the point where Hooke’s Law is valid – If stress is higher than Hooke’s Law is not valid and can’t be used. – Ultimate strength • Maximum stress that a material can withstand • Important for brittle materials 7 Tensile Modulus and Yield Strength • Modulus of Elasticity (E) or – Young’s Modulus is the ratio of stress to corresponding strain – A measure of stiffness • Yield Strength – Measure of how much stress a material can withstand without breaking – Modulus Yield Strength • • • • • • • • • • • • Stainless Steel Aluminum Brass Copper Molybdenum Nickel Titanium Tungsten Carbon fiber Glass Composites Plastics E= 28.5 million psi (196.5 GPa) E= 10 million psi E= 16 million psi E= 16 million psi E= 50 million psi E= 30 million psi E= 15.5 million psi E= 59 million psi E= 40 million psi E= 10.4 million psi E= 1 to 3 million psi E= 0.2 to 0.7 million psi 8 Hooke’s Law • Hooke’s Law relates stress to strain by way of modulus – Hooke’s law says that strain can be calculated as long as the stress is lower than the maximum allowable stress or lower than the proportional limit. • If the stress is higher than the proportional limit or max allowable stress than the part will fail and you can’t use Hooke’s law to calculate strain. – – – – – Stress = modulus of elasticity, E, times strain Stress= = load per area, P/A Strain= = deformation per length, /L Rearrange Hooke’s law Solving for deformation is Equation 10-5 E P ( Lf L ) E E A L L • With these equations you can find PL – How much a rod can stretch without breaking. AE Eqn 10-3 Eqn 10-4 Eqn 10-5 – What the area is needed to handle load without breaking – What diameter is needed to handle load without breaking • Example 10-1 • Example 10-3 9 Problem solving techniques • Steps to solve most Statics problems – Set-up problem • • Draw picture and label items (D, L, P, Stress, etc..) List known values in terms of units. – Solve problem 1. Make a Force balance with Free body diagram • • Identify normal forces Identify shear forces 2. Write stress as Force per unit area • • Calculate area from set-up, or Calculate force from set-up 3. Write Hooke’s law • • Rearrange for deflections Write deflections balance 4. Solve for problem unknowns E P A A Pallow allow A P ( Lf L ) E E A L L PL AE Pallow allow Eqn 10-3 Eqn 10-4 Eqn 10-5 10 Allowable Stresses and Factor of Safety • Factor of Safety 11 Stress Concentrations • Stress is concentrated near holes 12 Elastic Design versus Plastic Design • Ignore this section 13