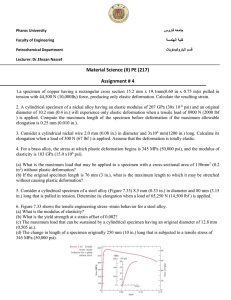

SOLUTION_ASSIGNMENT_CHAPTER_6

advertisement

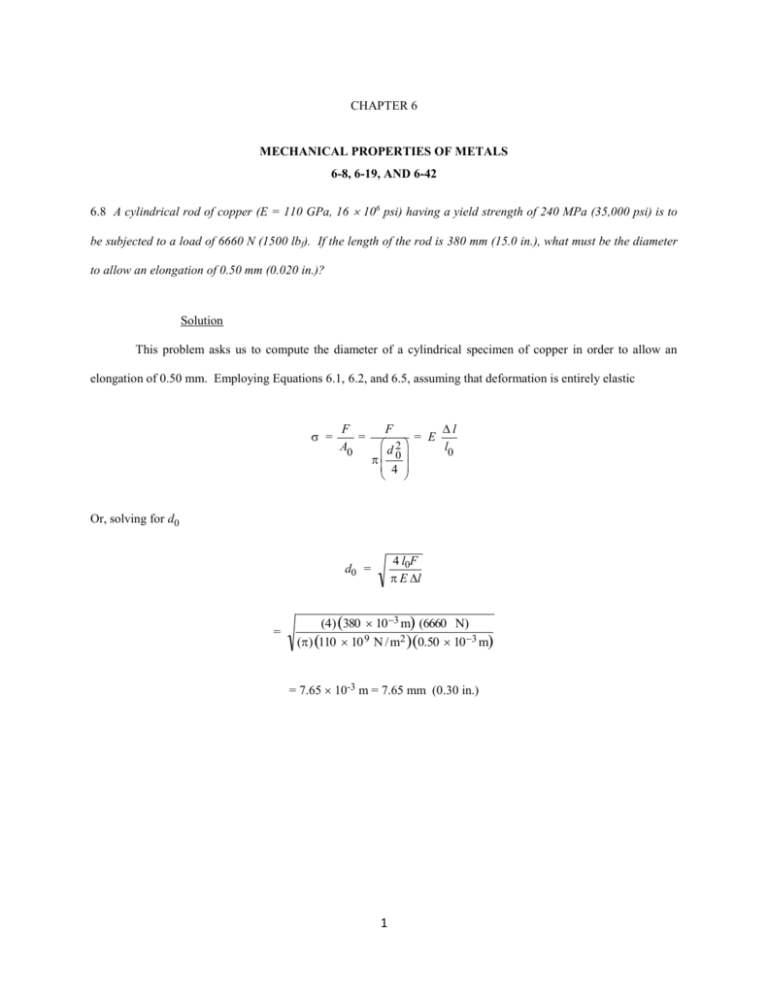

CHAPTER 6 MECHANICAL PROPERTIES OF METALS 6-8, 6-19, AND 6-42 6.8 A cylindrical rod of copper (E = 110 GPa, 16 106 psi) having a yield strength of 240 MPa (35,000 psi) is to be subjected to a load of 6660 N (1500 lb f). If the length of the rod is 380 mm (15.0 in.), what must be the diameter to allow an elongation of 0.50 mm (0.020 in.)? Solution This problem asks us to compute the diameter of a cylindrical specimen of copper in order to allow an elongation of 0.50 mm. Employing Equations 6.1, 6.2, and 6.5, assuming that deformation is entirely elastic = Or, solving for d0 F = A0 F l = E d 2 l0 0 4 4 l0F E l d0 = (4) (380 10 3 m) (6660 N) = () (110 10 9 N / m2 )(0.50 10 3 m) = 7.65 10-3 m = 7.65 mm (0.30 in.) 1 6.19 Consider a cylindrical specimen of some hypothetical metal alloy that has a diameter of 8.0 mm (0.31 in.). A tensile force of 1000 N (225 lbf) produces an elastic reduction in diameter of 2.8 10-4 mm (1.10 10-5 in.). Compute the modulus of elasticity for this alloy, given that Poisson's ratio is 0.30. Solution This problem asks that we calculate the modulus of elasticity of a metal that is stressed in tension. Combining Equations 6.5 and 6.1 leads to E = F = = z A0z F 2 d z 0 2 = 4F z d02 d From the definition of Poisson's ratio, (Equation 6.8) and realizing that for the transverse strain, x= d0 d z = x = d0 Therefore, substitution of this expression for z into the above equation yields E = = 4F z d02 = 4F d0 d (4)(1000 N )(0.30) = 1.705 10 11 Pa = 170.5 GPa (24.7 (8 10 3 m)( 2.8 10 7 m) 2 10 6 psi) 6.41 Using the data in Problem 6.28 and Equations 6.15, 6.16, and 6.18a, generate a true stress–true strain plot for aluminum. Equation 6.18a becomes invalid past the point at which necking begins; therefore, measured diameters are given below for the last four data points, which should be used in true stress computations. Load Length Diameter N lbf mm in. mm in. 46,100 10,400 56.896 2.240 11.71 0.461 42,400 10,100 57.658 2.270 10.95 0.431 42,600 9,600 58.420 2.300 10.62 0.418 36,400 8,200 59.182 2.330 9.40 0.370 Solution These true stress-strain data are plotted below. 3 6-42: A tensile test is performed on a metal specimen, and it is found that a true plastic strain of 0.2 is produced when a true stress of 575 Mpa; for the same metal the value of K is 860Mpa; calculate the true strain that results from the application of a true stress of 600Mpa Solution: True stress is given by, 𝜎𝑇 = 𝐾 ∈𝑛𝑇 Taking ln each side of the equation gives, 𝑛 = So, 𝑛 = ln 𝜎𝑇 −ln 𝐾 ln ∈𝑇 ln 575−ln 860 ln 0.2 = 0.25 Now the true strain when applied true stress, 𝜎𝑇 = 600 𝑀𝑝𝑎 ∈𝑇 = 𝑒 ln 𝜎𝑇 −ln 𝐾 𝑛 4 =𝑒 ln 600−ln 860 0.25 = 0.237