MSE 445: Ceramic Processing - Department of Materials Science

advertisement

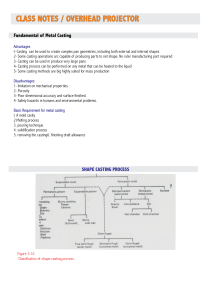

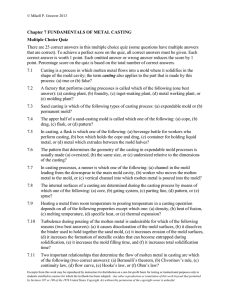

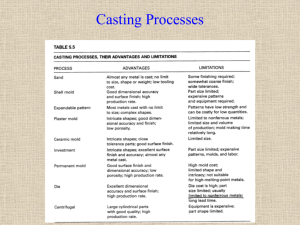

MSE 440/540: Processing of Metallic Materials Instructors: Yuntian Zhu Office: 308 RBII Ph: 513-0559 ytzhu@ncsu.edu Lecture 3: Casting I, Department of Materials Science and Engineering 1 NC State University Casting process Department of Materials Science and Engineering 2 NC State University USS New York LPD 21 Built from 24 tons of scrap steel from the World Trade Center The steel was melted down in a foundry in Amite, LA to cast the ship’s bow section. When it was poured into the molds on Sept 9, 2003, “those big rough steelworks treated it with total reverence”, recalled Navy Capt. Kevin Wensing. Department of Materials Science and Engineering 3 NC State University Our focus here is relatively small parts Advantages: • Can create complex part geometries • Can produce net-shape parts • Cheap Disadvantages : – Limitations on mechanical properties – Poor dimensional accuracy and surface finish for some processes; e.g., sand casting – Safety hazards to workers due to hot molten metals Department of Materials Science and Engineering 4 NC State University Open Molds and Closed Molds Two Categories of Casting Processes 1. Expendable mold processes – one time use – Mold materials: sand, plaster, and similar materials, plus binders 2. Permanent mold processes – multiple use – Made of metal (or, less commonly, a ceramic refractory material) Department of Materials Science and Engineering 5 NC State University Sand Casting Mold Definition: Cope, Drag, parting line, riser, runner, cavity, core, downsprue Department of Materials Science and Engineering 6 NC State University Cooling Curve for a Pure Metal • A pure metal solidifies at a constant temperature equal to its freezing point (slightly below melting point) NC State University Riser Reservoir in the mold which is a source of liquid metal to compensate for shrinkage of the part during solidification • The riser must be designed to freeze after the main casting in order to satisfy its function • To minimize waste in the unit operation, it is desirable for the volume of metal in the riser to be a minimum • Since the shape of the riser is normally designed to maximize the V/A ratio, this allows riser volume to be reduced to the minimum possible value Quiz: why do we want to maximize the V/A ratio? NC State University Solidification of Pure Metals • Due to chilling action of mold wall, a thin skin of solid metal is formed at the wall surface immediately after pouring • Grain structure in a casting of a pure metal, showing randomly oriented grains of small size near the mold wall, and large columnar grains oriented toward the center of the casting http://www.youtube.com/watch?v=M95bhPrDwA0 NC State University Solidification of Alloys • Most alloys freeze over a temperature range • Phase diagram for a copper-nickel alloy system and cooling curve for a 50%Ni-50%Cu composition Quiz: any problem with this cooling curve? NC State University Solidification of Alloys • Characteristic grain structure in an alloy casting, showing segregation of alloying components in center of casting NC State University Cellular and Dendritic Solidification Constitutional Supercooling: T k= T1 Cell Structure: T2 XS XL XL T3 XS TE XE Dendritic structure: X0 Condition for non-constitutional cooling (Planar): T1 - T3 T > Dv ' L Department of Materials Science and Engineering NC State University No Diffusion in Solid, Diffusional Mixing in Liquid ìï 1 - k - x üï X L = X 0 í1+ e Dvý ïî ïþ k D/v = Characteristic width of concentration profile Fig. 4.22, T k= T1 T2 T3 XS XL XL XS TE XE X0 Department of Materials Science and Engineering NC State University Solidification Time • Total solidification time tTS = time required for casting to solidify after pouring • tTS depends on size and shape of casting by relationship known as Chvorinov's Rule n tTS æV ö = Cm ç ÷ è Aø where V = volume of the casting; A = surface area of casting; n = exponent with typical value = 2; and Cm is mold constant. NC State University Shrinkage during Solidification and Cooling NC State University HW Assignment • Read Chapter 6 • HW: Example 5.2 on page 109 • Problems 5.8, 5.9, 5.11, 5.12, 5.13,5.16 • Quiz for online students: why the columnar structure grow perpendicular to the mold wall? (submit it directly to Dr. Zhu by email: ytzhu@ncsu.edu) Department of Materials Science and Engineering 16 NC State University