Main Electrical Survey Items, Generators and Governors , Circuit

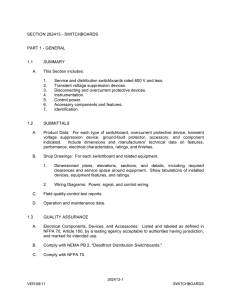

advertisement

MAIN ELECTRICAL SURVEY ITEMS, GENERATORS AND GOVERNORS, , CIRCUIT BREAKERS, SWITCHBOARDS AND FITTINGS (Adapted from:D.T. Hall:Practical Marine Electrical Knowledge) Main Electrical Survey Items The following survey items apply in general to all ships: Generators and Governors Circuit-Breakers Switchboards and Fittings Cables Insulation Resistance Motors and Starters Emergency Power Equipment Parts of Steering Gear Navigation Light Indicators UMS TANKERS For UMS operation, a survey of the associated alarms, controls and fire detection is required. Generators and Governors 169 For tankers/gas carriers and other ships transporting flammable cargo, an additional survey of all electrical equipment in hazardous areas is carried out during each docking survey and annual survey. This means that hazardous area electrical equipment is surveyed every year. Generators and Governors The surveyor will require that main and emergency generators are clean, respond correctly to controls and load changes, and show stable operation when required to run in parallel with other generators. Generator windings on stator and rotor must be free of dust, oil and moisture. A visual check will be made for any obvious deterioration, abrasion or cracking of the insulation around the end winding coils on the stator. An insulation test to earth and between stator phase windings (if the neutral point can be disconnected at the terminal box) should be carried out while the machine is still hot after running on load. Circuit Breakers A visual examination of circuit-breakers in main, emergency and section boards will usually precede operational tests. The surveyor will particularly check the condition of main, arcing and auxiliary contacts for signs of wear, misalignment and overheating. A similar inspection of fixed and moving isolator contacts at the rear of a circuit-breaker will be made. Arc chutes must be clean, free of arc debris and correctly aligned. All internal wiring should be in good condition and its end connections must be tight. All mechanical linkages will be checked for any signs of wear or stress. Tests on a circuit-breaker will include close and trip operations while in its isolated position (i.e. not connected in circuit). The racking mechanism for moving the breaker from the service to the isolated position must be demonstrated to be free moving and the fixed main terminals must be seen to be shuttered off when the breaker is withdrawn. Emergency hand charging (if fitted) of the closing spring will be tested. Correct operation of the mechanical indicators to show whether the breaker is open, closed or isolated, is required. The undervoltage release mechanism and overcurrent trip settings for level and time delay may have to be demonstrated to the surveyor's satisfaction. An overcurrent trip for a generator breaker is typically set for 130% of full load current (FLC) with a typical time delay of 3 s, but this has to suit the thermal capacity of the generator and be co-ordinated with the overall protection scheme for the power system. Although the overcurrent and time delay settings on the breaker can be seen to be correctly adjusted to the desired values, only a proper current injection test will prove these settings against the manufacturer's I/t characteristics. In this test the circuit-breaker is isolated from the busbar and a set of calibrated currents from a current injection set are fed directly through the closed circuit-breaker (primary injection) or (more usually) through the overcurrent relay (secondary injection). This is generally a specialist task for an outside contractor Circuit-breaker time delay mechanisms with oil dash1 pots must have the pots filled to Site correct level with clean oil of a type recommended by the manufacturer. Switchboards and Fittings An obvious survey requirement for any switchboard, section board or distribution board is that they are clean. This includes all internal surfaces as well as the external panel surfaces, instrument faces and control switches. A thorough cleaning job on the inside of the main switchboard can only be safely carried out when the board is completely dead (all generators stopped and prime movers locked-off). All the main bus-bar and auxiliary connections throughout the boards should be checked for tightness during the dead period of a major internal clean up. Overheating signs at a connection junction are probably due to a loose joint. Direct heat testing on load with an infra-red thermal camera is now a very useful technique for locating hot-spots. Bus-bar supports will be examined for surface tracking and damage to the insulation material. All internal wiring within the switchboard panels must be securely fixed. Cable entries at the bottom of the switchboard should be sealed with a non-flammable material to exclude dirt and act as a fire stop. The main switchboard earth bar must be securely bonded to both the frame of the board and, of course, to the ship's hull. One secondary terminal of each current transformer (CT) and the metal cases of instruments and relays should be wired to the main earth bar. Hinged panel doors should be bonded with an earth strap to the main switchboard frame.