AWPI Meeting, April 27

advertisement

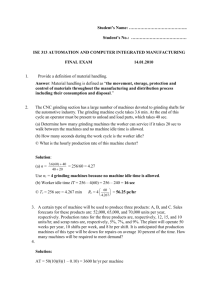

On-line Sorting Technology for CCA-Treated Wood Funding Received from Sarasota County through the Florida Department of Environmental Protection Innovative Recycling Grants Program Objective Construct and Operate an On-Line System for Sorting Treated From Untreated Wood Background Research conducted found CCA-treated wood in C&D waste piles 6% in 1996 (12 C&D facilities) 9 to 30% in 1999 (3 C&D facilities) Background U.S. Statistics for Southern Pine Production 1.6 Untreated 1.4 1.2 1 0.8 0.6 0.4 0.2 (From SFPA) 1998 1996 1994 1992 1990 1988 1986 1984 1982 0 1980 billion cubic feet Treated Conceptual Design Control Detector Room Conveyor 10’ Wood Pile Closed In 5’ 7’ 7’ 40’ 18’ Control Room Untreated Pile Window 3’ 4’ 30’ 2’ Wood Input Treated Pile d te Input Wood Storage Pile Untreated Wood a Tre 14’ Detector Conveyor o Wo d 30’ 3’ 4’ 16’ Conceptual Design (con’d) Inlet Conveyor To Untreated Pile Pile Initially Separation Here Will Be Done Manually te d A buzzer will sound or a light will shine when CCA is detected Exit Conveyor a Tre To Detector Wood Sample Tasks Task 1: Obtain Permit and Construct Shelter Task 2: Design and Construct Conveyor Task 3: Lab Test and Develop Detector (Laser, LIBS vs X-ray, XRF) Task 4: Install and Field Test Conveyor and Detector Task 5: Operate Sorting System and Document Performance Overall Timeline Description 2000 M A M J J F M A M J J A S X X Task 4: Install and Field Test Conveyor and Detector Task 5: Operate Sorting System and Document Performance Submit Environ. Certification and Scope X of Services Progress Reports Final Report A S O N D X Task 1: Obtain Permit and Construct Shelter Task 2: Design and Construct Conveyor Task 3: Lab Test & Develop Detector J 2001 X X X X X X X X Task 1: Obtain Permit and Construct Shelter Outline Specifications and location of shelter Construction process Shelter construction contractors Project management Project schedule Shelter Description Metal fabricated building 30 by 40 feet, 15 foot eave height Portal frame with open sides, 1:12 sloped roof Engineered concrete slab Approximate Size and Roof Line Portal Frame Open Sides and Height Site Layout Machine Shop Proposed Parking Wood Out Bin Shelter C&D Materials Processing Area Wood In Office Trailer Parking Entrance C&D Material Storage Bins Shelter Location Construction Process Metal fabricator - shelter design County engineer - concrete design Slab Anchor bolts Electric - separate subcontractor Anchor Bolt Detail Available Electric Shelter Contractor Quotes Uni-Built, Tampa, FL Dura-Steel, Vernon, FL Trident, Sarasota, FL Ranged $9,000 - $17,000 Project Management Review plans and permit documents Coordinate inspection schedule of foundations, structural steel and electrical system Review work in-place prior to scheduled inspection by Building Department Prepare written summary of field inspections July August 28 4 1 Wk September 21 1 October 15 1 12 27 PO/Contract Finalized 2 Wk 2 Wk Building Contractor Develops Design Drawing 5 Wks Review and Concrete/Electrical Design Permit Review 6 Wks 3 Wks Fabrication and Delivery Concrete Slab Schedule and Timeline Erect Building Install Electric Task 2: Design and Construct Conveyor Conveyor (Task 2) Preliminary Quotes American Conveyor, Miami, FL ** Powerscreen, Lakeland, FL Conveyor (Task 2) Conveyor, 5’ wide Laser 12’ 5’ 3’ 10’ 15’ XRF Detec tor Table Roller Conveyor Belt Conveyor 30 O Inc lined Belt Conveyor Most Recent Design Roll-off Conveyor (Task 2) 40’ 10’ Incoming Wood 10’ 5’ Inc line Conveyor 30’ Control Room 5’ Roll-off 15’ CCA-Treated Wood Other Wood Types Task 3: Lab Test and Develop Detector LIBS vs XRF Funds will be used for LIBS Research with XRF will continue if equipment “borrowing” arrangement can be made Laser-induced Breakdown Spectroscopy (LIBS) Laser-induced plasma Line position provides species identification Line intensity provides species concentration Be Atomic emission collection Fiber optic Spectrometer Detector Cd Intensity Pulsed laser 205 Cd Cd 210 215 220 225 230 235 Wavelength (nm) 240 245 LIBS Spectrum of CCA-treated Wood 14000 Weathered Calcium (422.67) Emission Intensity 12000 10000 8000 Chromium 425.54 427.48 428.97 6000 4000 2000 0 410 415 420 425 Wavelength (nm) 430 435 440 LIBS-based Sorting 60 LIBS Chromium Signal 50 40 CCA-treated Wood 30 20 Untreated Wood 10 0 0 1 2 3 4 Wood Sample 5 6 7 Sample Configuration of LIBS Probe Nd:YAG Laser To Laptop Computer Spectrometer/ Detector Collection Optics Assembly Plasma Wood Sample Field-deployable Laser: Big Sky Laser Compact Spectrometer: Ocean Optics On-line Sorting Technologies Custom LIBS Cost $36K Commercial XRF (Asoma) $20 to $30K Detection As, Cr, Cu As, Cr, Cu As, Cr, Cu Analysis time 3 ms @ 10 Hz 50 to 100 s 100 to 500 ms Spatial resolution (1 ft/sec) Standoff distance (Detector-to-wood) Other issues Point Start/stop mode Continuous Maintenance 1.25" samples Custom XRF $100K 2.5" to 12" samples Variable Fixed ~Fixed 10-12" window Near contact Close proximity Laser beam X-ray source X-ray source $400 flashlamp ~35 weeks -- X-ray tube XRF ASOMA ----> Now Spectro Contact Harold Soisson Model 400 XRF Co XRF ----> Distributors of EDAX Contact Steve Cox Model, CT-2000 Note: As detection limit 5 mg/kg Questions? More information at: http://www.eng.miami.edu/~hmsolo/ sarasota/index_sara.htm Link from: www.ccaresearch.org