poster411_project_2G1_Term_121

advertisement

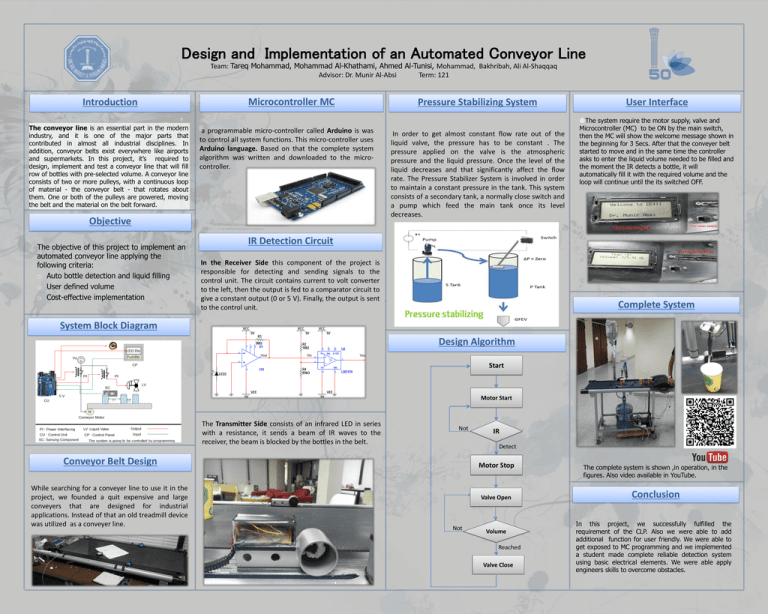

Design and Implementation of an Automated Conveyor Line Team: Tareq Mohammad, Mohammad Al-Khathami, Ahmed Al-Tunisi, Mohammad, Bakhribah, Ali Al-Shaqqaq Advisor: Dr. Munir Al-Absi Term: 121 Microcontroller MC Introduction The conveyor line is an essential part in the modern industry, and it is one of the major parts that contributed in almost all industrial disciplines. In addition, conveyor belts exist everywhere like airports and supermarkets. In this project, it’s required to design, implement and test a conveyor line that will fill row of bottles with pre-selected volume. A conveyor line consists of two or more pulleys, with a continuous loop of material - the conveyor belt - that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. a programmable micro-controller called Arduino is was to control all system functions. This micro-controller uses Arduino language. Based on that the complete system algorithm was written and downloaded to the microcontroller. Objective The objective of this project to implement an automated conveyor line applying the following criteria: o Auto bottle detection and liquid filling o User defined volume o Cost-effective implementation Pressure Stabilizing System In order to get almost constant flow rate out of the liquid valve, the pressure has to be constant . The pressure applied on the valve is the atmospheric pressure and the liquid pressure. Once the level of the liquid decreases and that significantly affect the flow rate. The Pressure Stabilizer System is involved in order to maintain a constant pressure in the tank. This system consists of a secondary tank, a normally close switch and a pump which feed the main tank once its level decreases. User Interface The system require the motor supply, valve and Microcontroller (MC) to be ON by the main switch, then the MC will show the welcome message shown in the beginning for 3 Secs. After that the conveyer belt started to move and in the same time the controller asks to enter the liquid volume needed to be filled and the moment the IR detects a bottle, it will automatically fill it with the required volume and the loop will continue until the its switched OFF. IR Detection Circuit In the Receiver Side this component of the project is responsible for detecting and sending signals to the control unit. The circuit contains current to volt converter to the left, then the output is fed to a comparator circuit to give a constant output (0 or 5 V). Finally, the output is sent to the control unit. Complete System System Block Diagram Design Algorithm + Start Motor Start The Transmitter Side consists of an infrared LED in series with a resistance, it sends a beam of IR waves to the receiver, the beam is blocked by the bottles in the belt. Not Detect Conveyor Belt Design While searching for a conveyer line to use it in the project, we founded a quit expensive and large conveyers that are designed for industrial applications. Instead of that an old treadmill device was utilized as a conveyer line. IR Motor Stop Valve Open Not Volume Reached Valve Close The complete system is shown ,in operation, in the figures. Also video available in YouTube. Conclusion In this project, we successfully fulfilled the requirement of the CLP. Also we were able to add additional function for user friendly. We were able to get exposed to MC programming and we implemented a student made complete reliable detection system using basic electrical elements. We were able apply engineers skills to overcome obstacles.