Cost of Poor Quality

Managers and workers speak

the language of things but

Senior leaders speak the

language of money...

…COPQ allows us to translate

the things into money.

Cost of Poor Quality 2 .PPT

All Rights Reserved, Juran Institute, Inc.

Cost of Poor Quality

Prevention

Cost of Attaining Quality

Appraisal: Prediction

Audit

Appraisal: Detection

Failure: Internal

External

Cost of Poor Quality 3 .PPT

Cost of Poor Quality

All Rights Reserved, Juran Institute, Inc.

Quality Costs

Components

$

Conformance

Non-Conformance

$

$

Cost of Poor Quality 4 .PPT

All Rights Reserved, Juran Institute, Inc.

Total Quality Cost

I want my

money

back!

Prevention

Internal

Failure

Appraisal

External

Failure

$

Cost of Quality (COQ)

Cost of Poor Quality 5 .PPT

All Rights Reserved, Juran Institute, Inc.

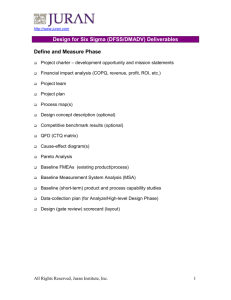

COPQ Overview

Definitions

All activities and processes that do not meet agreed

performance and/or expected outcomes

Costs that would disappear if every task were always

performed without deficiency

Actual Cost - Minimum Cost = COPQ

Cost of Poor Quality 6 .PPT

All Rights Reserved, Juran Institute, Inc.

Traditional Cost of Poor Quality

(4-5% of Sales)

When quality costs are initially determined, the categories

included are the visible ones as depicted in the iceberg below.

Waste

Testing Costs

Rejects

Rework

Cost of Poor Quality 7 .PPT

Customer Returns

Inspection Costs

Recalls

All Rights Reserved, Juran Institute, Inc.

Cost of Poor Quality

As an organization gains a broader definition of poor quality,

the hidden portion ofWaste

the iceberg becomes apparent.

Customer Returns

Rejects

Testing Costs

Inspection Costs

Rework

Recalls

Excessive Overtime

Late Paperwork

Pricing or

Billing Errors

Excessive Field

Services Expenses

Excessive

Employee Turnover

Planning Delays

Incorrectly Completed

Lack of Follow-up

Sales Order

on Current Programs

Customer Allowances

Premium Freight Costs

Overdue Receivables

Excessive

System Costs

Time with

Dissatisfied Customer

Development Cost of Failed Product

Cost of Poor Quality 8 .PPT

Excess Inventory

Unused Capacity

Complaint

Handling

COPQ ranges

from 15-25%

of Sales

High Costs

Hidden COPQ: The

costs incurred to

deal with these

chronic problems

All Rights Reserved, Juran Institute, Inc.

Quantifying the Potential Benefit

Sigma

Cost of Poor Quality 9 .PPT

Cost

6 sigma

<10% of sales

5 sigma

10-15% of sales

4 sigma

15-20% of sales

3 sigma

20-30% of sales

2 sigma

30-40% of sales

All Rights Reserved, Juran Institute, Inc.

What Does Reality Look Like?

The ratio of the individual category costs to total costs

varies widely. Many companies exhibit ratios which look

like the following:

Quality Cost Category

Percent of Total

Internal Failure

25 to 40

External Failure

25 to 40

Appraisal

10 to 50

Prevention

.05 to 5

What's Wrong With This Picture?

Cost of Poor Quality 10 .PPT

All Rights Reserved, Juran Institute, Inc.

Examples of Prevention Expense

Quality Planning

Training and Education

Process Definition

Customer Surveys

Preproduction Reviews

Technical Manuals

Detailed Product

Engineering

Early Approval of Product

Specifications

Cost of Poor Quality 11 .PPT

Purchase Cost Targets

Process Capability

Studies

Preventive Maintenance

Supplier Qualification

Job Descriptions

Housekeeping

Zero-Defect Program

All Rights Reserved, Juran Institute, Inc.

Examples of Appraisal Expense

Test

Inspection

Process Controls

Train QA Personnel

Product Audits

Quality Systems Audits

Customer Satisfaction

Surveys and Audits

Prototype Inspection

Accumulating Cost Data

Cost of Poor Quality 12 .PPT

Supplier Certification

Employee Surveys

Security Checks

Safety Checks

Reviews:

– Operating Expenditures

– Product Costs

– Financial Reports

– Capital Expenditures

All Rights Reserved, Juran Institute, Inc.

Examples of Internal Failure Costs

Substandard Product

Scrap or Rework

Re-inspection

Redesign/Engineering

Change

Process Modifications

Payroll Errors

All Expediting Costs

Off-Spec/Waiver

Abandoned Programs

Cost of Poor Quality 13 .PPT

Supplier Problems

– Scrap and rework

– Late deliveries

– Excess inventory

Equipment Downtime

Accidents, Injuries

Absenteeism

Unused Reports

Missed Schedule Cost

Lost Sales (any cause)

All Rights Reserved, Juran Institute, Inc.

Examples of External Failure Costs

Product Recall

Handling Complaints

Customer Service

Caused by Errors

Products Returned

Analysis of Returns

Evaluation of Field Stock

Late Payments and

Bad Debts

Lawsuits

Reports

– Sales and service

– Returns and allowances

– Failure

Lost Sales Because of Customer Dissatisfaction!

Cost of Poor Quality 14 .PPT

All Rights Reserved, Juran Institute, Inc.

Non-value Added Work

Definition

Common activities that provide no benefit to customers.

Some result from internal or external failure

Some are unnecessary inspection

Examples

Rarely used information systems

Memos never read

Financial reports not used

Irrelevant procedures

Meetings with no objectives or outcomes

Cost of Poor Quality 15 .PPT

All Rights Reserved, Juran Institute, Inc.

The Hidden Organization

Step

1

Test

Step

2

Test

Product

Floor Space

Analyze

Analyze

Fix

Fix

Floor Space

Floor Space

The Hidden Factory

Value Added

Non-Value Added

Philip R. Thomas, Competitiveness

Through Total Cycle Time. McGraw-Hill

(1990)

“Theoretical Cycle Time: The back-to-back process time

required for a single unit to complete all stages of a task

without waiting, stopping, or setups.”

Cost of Poor Quality 16 .PPT

All Rights Reserved, Juran Institute, Inc.

Why Cost of Poor Quality?

Reporting Tool

Comparisons

Trends

Analytical Tool

Priorities

Tradeoffs

Investment Tool

ROI

Cost of Poor Quality 17 .PPT

All Rights Reserved, Juran Institute, Inc.

Focus of COPQ Efforts

Identify and Quantify Quality Costs

Expose the “Hidden Factory”

Ongoing Measurement System

Breakthrough Improvement

Cost of Poor Quality 18 .PPT

All Rights Reserved, Juran Institute, Inc.

Advantages of Using Quality Costs for Management

Advantages

Reducing the cost of poor quality is one of the best ways to

increase a company's profit.

Provides manageable entity and a single overview of quality.

Aligns quality and goals.

Prioritizes problems and provides a means to measure

change/improvement.

Provides a means to correctly distribute controllable quality

cost for maximum profits.

Promotes the effective use of resources.

Provides incentives for doing the job right every time.

Cost of Poor Quality 19 .PPT

All Rights Reserved, Juran Institute, Inc.