http://www.juran.com

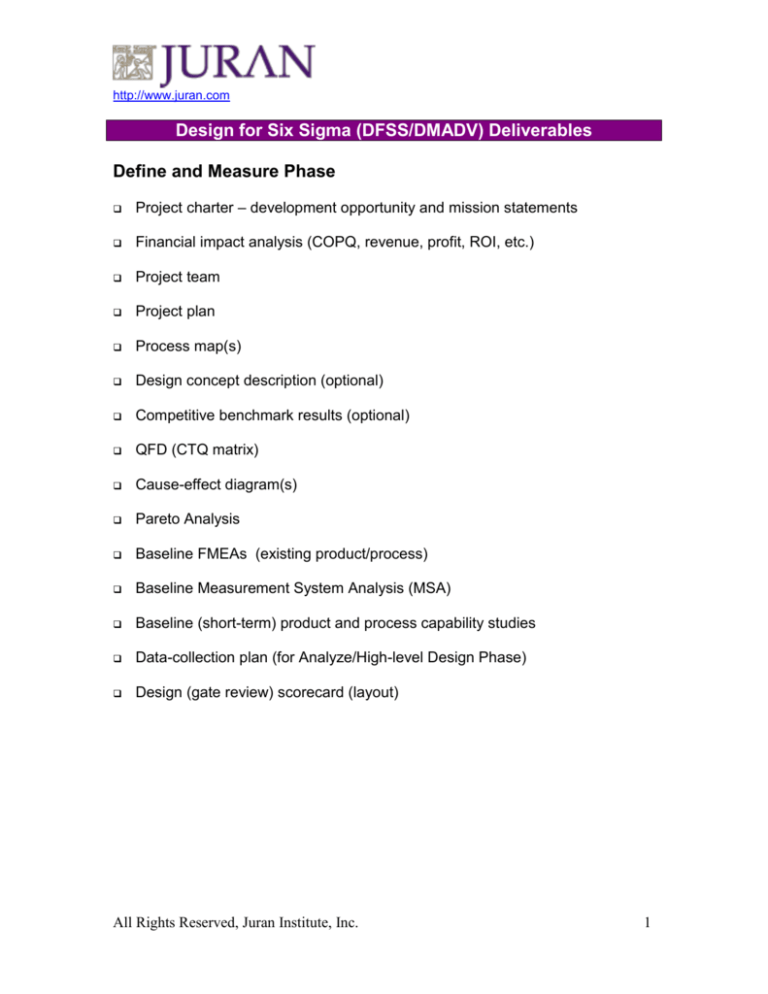

Design for Six Sigma (DFSS/DMADV) Deliverables

Define and Measure Phase

Project charter – development opportunity and mission statements

Financial impact analysis (COPQ, revenue, profit, ROI, etc.)

Project team

Project plan

Process map(s)

Design concept description (optional)

Competitive benchmark results (optional)

QFD (CTQ matrix)

Cause-effect diagram(s)

Pareto Analysis

Baseline FMEAs (existing product/process)

Baseline Measurement System Analysis (MSA)

Baseline (short-term) product and process capability studies

Data-collection plan (for Analyze/High-level Design Phase)

Design (gate review) scorecard (layout)

All Rights Reserved, Juran Institute, Inc.

1

http://www.juran.com

Analyze and High-level Design Phase

List of design alternatives

QFD (functional deployment matrix) – documented list of product functions

that meet CTQs

QFD (process deployment matrix) – documented list of process functions that

meet CTQs

Cause-effect diagram/matrix

List of hypotheses (design alternatives; key design parameter – X –

combinations) to be tested

Data-collection plan (for key Xs)

Results of hypothesis tests

Selected high-level design – documented superior system design

Documented design parameter database with estimated transfer functions (to

CTQs)

Initial manufacturability/assembleability assessment (optional)

Initial reliability assessment (optional)

Updated financial impact analysis (COPQ, revenue, profit, ROI, etc.)

Updated FMEAs (for selected high-level design)

List of “vital few” design parameters (Xs) for further analysis in detail Design

Phase

Updated design (gate review) scorecard

All Rights Reserved, Juran Institute, Inc.

2

http://www.juran.com

Verify Phase

Results of Manufacturing Verification Test (MVT)/pilot test

Control plan

Control chart design (for operations)

Data-collection plan (for key Xs to be monitored via control charts)

6S action plan (as applicable)

Mistake proofing (poka-yoka) plan (as applicable)

Validated/updated MSA

Updated Process Flow Diagram (PFD)

Updated FMEAs

Updated long-term product and process capability studies

Updated design parameter database and validated transfer functions

Updated reliability analysis and life test performance

Updated financial impact statement (COPQ, revenue, profit contribution, etc.)

Final design (gate review) scorecard

Ramp-up to mass production/implementation plan (optional)

Manufacturing process operational Six Sigma (DMAIC) deployment plan

All Rights Reserved, Juran Institute, Inc.

3