LBCC - Mod3 SOP2.0

advertisement

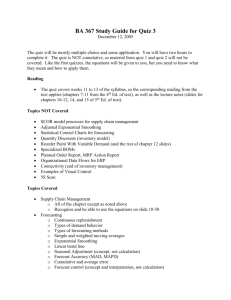

Introduction to Global Supply Chain Management Module Three: Sales & Operations Planning In The Age of Globalization This project received $24.5M (100% of its total cost) from a grant awarded under TAACCCT, as implemented by the U.S. Department of Labor’s Employment and Training Administration. This is an equal opportunity program and auxiliary aids and services are available upon request to individuals with disabilities. 1 Class Agenda • Sales & Operations Planning (S&OP) defined – Components & activities • • • • Buy-Side & Sell-Side elements of international trade Material Requirements Planning Distribution Requirements Planning Introduction to Inventory Management 2 The Essence of Supply Chain Management: Buy-Side & Sell-Side Activities In An Outsourced World S U P P L I E R S MANUFACTURER DISTRIBUTION SYSTEM MATERIALS MANAGEMENT DISTRIBUTION MANAGEMENT Buy-Side Sell-Side C U S T O M E R S 3 Sales & Operations Planning “Sales & Operations Planning is a multi-functional business discipline that helps companies to synchronize product supply with customer demand. Designed as an ongoing process, S&OP uses updated forecasts to translate high-level supply chain strategies into operational activities that include production planning, material requirements planning, purchasing, distribution requirements planning, inventory management, sales, order management, logistics, finance and accounting. At its core, S&OP forces executives to constantly compare period-specific product forecasts with actual sales activities, and then make operational adjustments that reflect any variation between the two. Whereas the frequency and planning horizon for S&OP will vary by industry and company, S&OP is essential to making sure that an organization can achieve a balance between demand, inventories and profitability.” -Dan Gardner, April 2015 4 S&OP: Constantly Aligning Strategy, Tactics & Demand Marketing planning Strategic planning Financial planning Resource planning Production planning Demand management Master production scheduling Routing file Detailed capacity planning Shop-floor systems Bills of material Detailed material planning Front end Inventory status data Time-phased requirement (MRP) records Material and capacity plans Engine Vendor systems Back end 5 The S&OP Challenge: Integrating & Synchronizing Functional Activities • • Sales forecasting Materials Requirements Planning – Supplier Relationship Management • Distribution Requirements Planning – Customer Relationship Management • • Inventory Management Demand Management – Available to Promise – Order Management 6 Sales & Operations Planning: Objectives & Outcomes • Link high-level strategy with tactical execution – Marketing – Production – Finance • Greater alignment between the BuySide & Sell-Side of the supply chain – Supplier Relationship Management – Customer Relationship Management 7 Sales & Operations Planning: Objectives & Outcomes • Improved sales – Existing products – New product launches • • • • • More accurate forecasts End-to-end supply chain visibility Control over landed costs & profit margins Reliable lead times Enhanced inventory management – No lost sales – Minimal obsolete inventory 8 The “Cascade Effect” of Forecasting on Sales & Operations Planning 9 S&OP: Everything Starts with a Forecast Marketing planning Strategic planning Financial planning Resource planning Production planning Demand management Master production scheduling Routing file Detailed capacity planning Shop-floor systems Bills of material Detailed material planning Front end Inventory status data Time-phased requirement (MRP) records Material and capacity plans Engine Vendor systems Back end 10 Characteristics of The Forecasting Discipline • • Virtually all supply chain (S&OP) activities begin with a forecast Because forecasting involves predicting the future, they are almost always wrong – Predicting future sales – Budgeting for future costs – Planning for capital expenditure • Differences between forecasts and actual results should be calculated as soon as posible and made a part of future planning 11 Forecasting & SCM • • The forecasting function is a primary building block of S&OP, Supply Chain Management and inventory management Forecasting of independent demand permeates the entire Supply Chain – Independent demand determines dependent demand (Quantities of raw materials needed to manufacture products) – Both independent & dependent demand impacts inventory levels throughout the Supply Chain 12 Characteristics of The Forecasting Discipline • • • Consuming the Forecast is the cornerstone of Sales & Operations Planning Forecasts should be carried out on a long, medium, short and immediate basis Performed only for “Independent Demand” items (finished goods) 13 Characteristics of The Forecasting Discipline • Must consider cycles, trends, seasonality & random variation – Retail: Seasons, events & holidays – Importance of the “Retail Calendar” • • Forecasts are more accurate for families or groups of products Forecasts are more accurate for nearer time periods 14 Sales & Operations Planning: The Integration & Synchronization of Buy-Side Activities S U P P L I E R S MANUFACTURER DISTRIBUTION SYSTEM MATERIALS MANAGEMENT DISTRIBUTION MANAGEMENT Buy Side Sell Side C U S T O M E R S 15 Buy-Side Activities: Material Requirements Planning (MRP) • • MRP is a time-phased approach to planning for the procurement of raw materials that will go into a production process MRP activities are based on the Master Production Schedule – What products will be manufacturered – Quantities to be produced – During a specific “time bucket” 16 Materials Requirements Planning • Forecasts for finished goods (independent demand) are what drive the MPS and MRP – Independent demand for finished goods drives dependent demand for raw materials – The “Cascade Effect” • MRP for specific products is driven by the “Bill of Material” – A “recipe” for the raw materials that go into making a product • MRP software provides productspecific information on what to order, in what quantity and when to place a purchase order 17 Materials Requirements Planning • As part of the S&OP process, MPS & MRP quantities will change based on updated forecasts – Adjustments made to the MPS & MRP driven by actual demand – Consuming the forecast • Two essential activities related to MRP are: – Gross to Net Exploding – Lead-time Offsetting • MRP has a direct impact on sales, landed costs, lead times and inventory levels 18 The Heart of the Tactical Matter: Material Requirements Planning (Buy Side) Material Requirements Planning (MRP)-A set of techniques that use Bill of Material data, inventory data and the master production schedule to calculate requirements for materials. It makes recommendations to release replenishment orders for material. Further, because it is time-phased, it make recommendations to reschedule open orders when due dates and need dates are not in phase. Time-phased MRP begins with the items listed on the MPS and determines (1) the quantity of all components and materials required to fabricate those items and (2) the date that the components and material are required. Time-phased MRP is accomplished by exploding the bill of material, adjusting for inventory quantities on hand or on order, and offsetting the net requirements by the appropriate lead times. Source: APICS Dictionary 19 Integrating S&OP: MPS, MRP, Inventory Management & Logistics • Gross–to-Net Exploding – An exercise whereby the original (gross) requirement for a product is reduced by: • • • • • • Inventory on hand Confirmed order receipts Confirmed order releases Planned order releases Gross-to-Net Exploding must be integrated with the raw materials inventory management function Integration is achieved through process design and supply chain software applications 20 Integrating S&OP: MPS, MRP, Inventory Management & Logistics • Lead time off-setting – Orders are placed for products on a date that “off-sets” cumulative lead times with the desired date of receipt • P.O. preparation/acceptance • Production time • Transportation lead time • Customs clearance • Domestics distribution • • Lead time off-setting must be integrated with the logistics function Integration is achieved through process design and supply chain software applications 21 Software-Based MRP Item Table Item: ABC Order Qty: 1,000 Lead Time: 2 weeks Time Bucket (week) Gross Requirements Scheduled Receipts Projected Available Net Requirements Planned Order Receipt Planned Order Release 1 2 3 4 5 Based on the MPS, BOM and available inventories, MRP software nets, offsets, explodes requirements and creates Planned Order Releases. As actual activity “Consumes the Forecast,” algorithms in the software automatically cascade updates to the MRP Product Records 22 Essential Information for MRP Item Record • • • • • • Item name, description, item number and Harmonized System number Vendor(s) Unit cost Unit of measure Stock locations Inventory classification (ABC) 23 Essential Information for MRP Item Record • • • • • • • Usage On-hand balance at each location Amount allocated On-order info by due date Re-order and safety stock information Order quantity Lead time 24 Sales & Operations Planning: The Integration & Synchronization of Sell-Side Activities S U P P L I E R S MANUFACTURER DISTRIBUTION SYSTEM MATERIALS MANAGEMENT DISTRIBUTION MANAGEMENT Buy-Side Sell-Side C U S T O M E R S 25 The Heart of the Tactical Matter: Distribution Requirements Planning (Sell-Side) Distribution Requirements Planning (DRP)-Intended for use with finished goods, DRP encompasses the activities associated with identifying the replenishment requirements of (warehouse) locations throughout a company’s logistics network. DRP uses the same logic as MRP in that it is a time-phased approach to determining inventory needs for each of an an organization’s stocking locations (satellite warehouse, regional distribution center, et al). Distribution Requirements Planning relies upon the principles of Gross-to-Net Exploding and Lead Time Off-Setting to synchronize product quantities and delivery times with actual demand. Because DRP is often used by companies with multi-level distribution networks (multiple warehouses), the discipline uses a “Bill of Distribution” to implode time-phased requirements from satellite warehouses up through the distribution channel to main distribution centers. Ideally, companies and their supply chain partners employ cloud-based visibility tools to truly integrate and synchronize all of their Sales & Operations Planning activities. Dan Gardner, April 2015 26 Software-Based DRP Product Table Time Bucket (week) Gross Requirements Scheduled Receipts Projected On-Hand (POH) Net Requirements Planned Order Receipt Planned Order Release 1 2 3 4 5 By using a product’s Bill of Distribution, DRP software implodes requirements up the distribution channel to create product-specific, time-phased Planned Order Releases. When S&OP activities are truly integrated and synchronized, DRP results will be cascaded back up the supply chain to Buy-Side functions like MPS & MRP. 27 Distribution Requirements Planning • • • Used for independent demand products (finished goods) within a company’s distribution network Calculates time-phased requirements in specific quantities Very similar to the logic behind MRP – Gross to Net Exploding – Lead-time Offsetting • Uses Bill of Distribution to implode needs up the distribution channel 28 Distribution Requirements Planning • Heavily influenced by customer orders – Backorders & current orders • • Consumption of the forecast integral to the process S&OP adjustments must be made based on variances between forecast & actual demand – Variances are cascaded back up the supply chain to Buy-Side activities 29 Elements of the DRP Discipline • • • • • Time periods (known as time buckets) Gross Requirements Scheduled Receipts Projected On-Hand Planned Order Receipt – Date & quantity of order • Planned Order Release – Based on BOD 30 Inputs to the DRP Process • • • • • • Item forecasts by due date Open customer orders by due date Beginning on-hand quantity by item Replenishment lead times by item Safety stock by item Order quantities by item 31 Outputs of the DRP Process • • • Projected On-Hand by time bucket Net Requirements by time bucket Exception Reporting – Identifies those items that require action • • Planned Orders by time buckets System-generated action messages – – – – – Release planned order Lead-time violation Expedite scheduled receipt De-expedite a scheduled receipt Cancel an order 32 Introduction to Global Inventory Management 33 Inventory Management Defined: • • Inventory Management: All activities associated with the valuation, acquisition, shipment, location, storage, sale, distribution, disposition, recovery and disposal of merchandise related to the operation of a firm’s business Goal is to meet the customer service requirements of the company – Product availability 34 Global Inventory Management: Integrating & Synchronizing the Supply Chain S U P P L I E R S Raw materials, components, sub-assemblies, work-in-process, finished goods, accessories, service parts, MRO MANUFACTURER DISTRIBUTION SYSTEM MATERIALS MANAGEMENT DISTRIBUTION MANAGEMENT Buy Side Sell Side C U S T O M E R S 35 Different Industries & Business Models Determine How Supply Chains Are Designed • • • • • • • Retailer (brick & mortar) E-Commerce Wholesaler/Distributor Manufacturer (OEM) Tier I, II or III supplier Agricultural importer/exporter Marketer/Merchandiser Different Types of Inventory & Operating Models Also Influence How Supply Chains Are Designed Operating Model Types of Inventory • • • • • • • • • • • • • • Raw materials Components/sub-assemblies Work In Process Finished goods Distribution inventory Accessories Spare parts MRO Build to stock Build to order Assemble to Order Engineer to Order Just In Time Vendor Managed Inventories 37 Global Inventory Management: Strategic & Tactical Considerations • • • Total dollar investment in global inventories Number and type of Stock Keeping Units (SKU’s) or Part Numbers to carry Locations of distribution centers, warehouses and/or satellite operations – By region and/or country • Risk Management policies & procedures 38 Global Inventory Management: Strategic & Tactical Considerations • • In-house inventory management or with a Third Party Logistics (3PL) company Systems integration – Inventory management system – Warehouse management system – Transportation management system • Accounting principles – First In/First Out – Last In/First Out 39 Global Inventory Management: Strategic & Tactical Considerations • Inventory accuracy Best Practices – ABC Analysis – Cycle Counting • • • • Safety stock levels Order points Min/Max levels Title transfer (Buy-Side & Sell-Side) 40 Regardless of the Model or Type of Inventory: I.M.-Related Costs to Consider • Ordering costs – Clerical & Admin support • Carrying costs – – – – – – – – Cost of capital Opportunity cost Lease Payroll Systems Materials handling equipment Maintenance Supplies 41 Regardless of the Model or Type of Inventory: I.M.-Related Costs to Consider • Transportation costs – Ocean, air, surface – Returns & reverse logistics • Risk management – Theft, pilferage & damage – Insurance – Security • Stock-out costs – – – – Expedited transport Back-order processing Lost sales Depletion of customer goodwill 42 End of Module Three Congratulations!!!