METHODS, STANDARDS, AND WORK DESIGN

advertisement

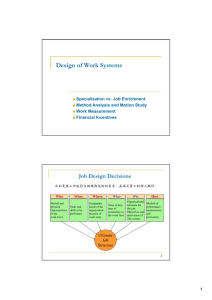

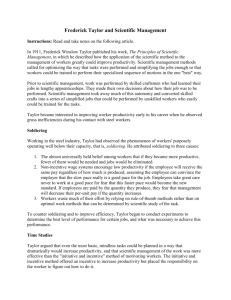

METHODS, STANDARDS, AND WORK DESIGN Chapter 1 The fundamental tools that result in increased productivity are: methods, time study standards, and work design. All aspects of a business or industry - sales, finance, production, engineering, cost, maintenance, and management - provide fertile areas for the application of methods, standards, and work design. Since the production area within manufacturing industries utilizes the greatest number of engineers in methods, standards, and work design efforts. In the production department for example, materials are requested and controlled; the sequence of operations, inspections, and methods is determined; tools are ordered; time values are assigned; work is scheduled, dispatched, and followed up; and customers are kept satisfied with quality products delivered on time. If the production department is considered the heart of an industrial enterprise, the methods, standards, and work design activity is the heart of the production group. They use initiative and creativity to develop efficient tooling, worker and machine relationships, and workstations on new jobs in advance of production. Also, they are creative in improving existing methods and products to help the company attain leadership in its product line. In this activity, good labor relations may be maintained through establishing fair labor standards. Methods, standards, and work design offer real challenges. Industries with competent engineers, business administrators, industrial relations personnel, specially trained supervisors, and psychologists all using methods, standards, and work design techniques are certainly better able to meet competition and better equipped to operate profitably. For example, The objective of the manufacturing manager is to produce a quality product, on schedule, at the lowest possible cost, with a minimum of capital investment and a maximum of employee satisfaction. The focus of the reliability and quality control manager is to maintain engineering specifications and satisfy customers with the product’s quality level and reliability over its expected life. The production control manager is principally interested in establishing and maintaining production schedules. The manager of methods, standards, and work design is mostly concerned with combining the lowest possible production cost with maximum employee satisfaction without sacrificing workplace safety. The maintenance manager is primarily concerned with minimizing facility downtime due to unscheduled breakdowns and repairs. Figure illustrates the relationship of the manager of the methods, standards, and work design department to the staff and line departments under the general manager. A—Cost is largely determined by manufacturing methods. B—Time standards are the bases of standard costs. C—Standards (direct and indirect) provide the bases for measuring the performance of production departments D—Time is a common denominator for comparing competitive equipment and supplies. E—Good labor relations are maintained with equitable standards and a safe work environment. F—Methods work design and processes strongly influence product designs. G—Standards provide the bases for preventive maintenance. H—Standards enforce quality. METHODS AND STANDARDS SCOPE Methods engineering includes designing, creating, and selecting the best manufacturing methods, processes tools, equipment, and skills to manufacture a product based on the working drawings that have been developed by the product engineering section. When the best method interfaces with the best skills, an efficient worker-machine relationship exists. Once the complete method has been established, the responsibility for determining the standard time required to produce the product falls within the scope of this work through (a) Predetermined Standards are met; (b) Workers are adequately compensated for their output, skills, responsibilities, and experience; and (c) Workers have a feeling of satisfaction from the work that they do. The overall procedure includes: defining the problem; breaking the job down into operations; analyzing each operation to determine the most economical manufacturing procedures for the quantity involved, with due regard for operator safety and job interest; applying proper time values; and then assuring that the prescribed method is put into operation. Figure illustrates the opportunities for reducing manufacturing time through the application of methods engineering and time study. METHODS ENGINEERING The terms operation analysis, work design and simplification, and methods engineering and corporate re-engineering are frequently used synonymously. The methods engineer is first responsible for designing and developing the various work centers where the product will be produced. Second, that engineer must continually re-study the work centers to find a better way to produce the product and to improve its quality. Methods engineering implies the utilization of technological capability. Methods engineers use a systematic procedure to develop a work center, produce a product, or provide a service. Select the project. Typically, the projects selected represent either new products or existing products that have a high cost of manufacture and a low profit, experiencing difficulties in maintaining quality and are having problems meeting competition are projects for methods engineering. Get and present the data. Assemble all the important facts relating to the product or service. These include drawings and specifications, quantity requirements, delivery requirements. Analyze the data. Utilize the primary approaches to operations analysis to decide which alternative will result in the best product or service. These primary approaches include: purpose of operation, design of part, tolerances and specifications, materials, process of manufacture, setup and tools, working conditions, material handling, plant layout, and work design. Develop the ideal method. Select the best procedure for each operation, inspection, and transportation by considering various constraints associated with each alternative, including productivity, ergonomics, and health and safety implications. Present and install the method. Explain the proposed method in detail to those responsible for its operation and maintenance. Consider all details of the work center, to insure that the proposed method will provide the results anticipated. Develop a job analysis. Conduct a job analysis of the installed method to insure that the operators are adequately selected, trained, and rewarded. Establish time standards. Establish a fair and equitable standard for the installed method. Follow up the methods. At regular intervals, audit the installed method to determine if the anticipated productivity and quality are being realized, whether costs were correctly projected, and whether further improvements can be made. WORK DESIGN As part of developing or maintaining the new method, the principles of work design must be used to fit the task and workstation ergonomically to the human operator. STANDARDS Standards are the end result of time study or work measurement. This technique establishes a time standard allowed to perform a given task, based on measurements of the work content ( that is time taken to manufacture the product or to perform the operation if the design or specification of product or service provided were perfect) of the prescribed method, with due consideration for fatigue and for personal and unavoidable delays. Time study analysts use several techniques to establish a standard: a stopwatch time study, computerized data collection, standard data, predetermined time systems, work sampling, and estimates based on historical data. The resulting standards are used to implement a wage payment scheme. In many companies, particularly in smaller enterprises, the wage payment activity is performed by the same group responsible for the methods and standards work. Production control, plant layout, purchasing, cost accounting and control, and process and product design are additional areas closely related to both the methods and standards functions. OBJECTIVES OF METHODS, STANDARDS, AND WORK DESIGN The principal objectives of methods, standards, and work design are: (a) to increase productivity and product reliability safely (b) to lower unit cost HISTORICAL DEVELOPMENTS FREDERICK W. TAYLOR Frederick W. Taylor is known as the father of scientific management and industrial engineering. He is the first person to use a stopwatch to study work content. Many years later, he established his four Principles of Scientific Management: 1. Develop a science for each element of a person’s work. 2. Select the best worker for each task and train that worker in the prescribed method. 3. Develop a spirit of cooperation between management and labor in carrying out the prescribed methods. 4. Divide the work into almost equal shares between management and labor, each doing what they do best. FRANK AND LILLIAN GILBRETH Frank and Lillian Gilbreth were the founders of the modern motion study technique, which may be defined as the study of the body motions used in performing an operation, to improve the operation by eliminating unnecessary motions, simplifying necessary motions, and then establishing the most favorable motion sequence for maximum efficiency. They developed theories of efficient motions through defining terminology of the entire range of manual motions. These 17 elementary subdivisions of motion, later engineers named a short word, therblig. HENRY LAURENCE GANTT Henry Laurence Gantt invented the task and bonus system or earnedhour plan. Rather than penalizing the less proficient worker as Taylor did with his multiple piecework plans, Gantt advocated a livable wage with a sizable bonus for performance over 100%. While Taylor emphasized the analytical and organizational aspects of work, Gantt was more interested in operator selection, training, and motivation. RALPH M. BARNES Dr. Barnes was one of the first and best-known professors of engineering in the field of work measurement. His achievements included writing the longest published text on work measurement, a thorough description of the Gilbreths’ micro-motion study, time study, and the procedure for work sampling. He conducted numerous methods studies of activities with motion picture cameras and developed rating films for training time study technologists. EMERGENCE OF WORK DESIGN Work design is a relatively new science that deals with designing the task, work station, and working environment to fit the human operator better. In the United States, it is more typically known as human factors, while internationally it is better known as ergonomics, which is derived from the Greek words for work (erg) and laws (nomos). Obviously, the growth of computers and technology will keep human factors specialists and ergonomists busy designing better workplaces and products and improving the quality of life and work for many years to come. ORGANIZATIONS Technical organizations have contributed much toward bringing the science of time study, work design, and methods engineering up to present-day standards. The Institute of Industrial Engineers (IIE) was founded in 1948 with the purposes of: maintaining the practice of industrial engineering on a professional level; fostering a high degree of integrity among the members of the industrial engineering profession; encouraging and assisting education and research in areas of interest to industrial engineers; promoting the interchange of ideas and in formation among members of the industrial engineering profession (e.g., publishing the journal IIE Transactions); In the area of work design, the first professional organization, the Ergonomics Research Society, was founded in the United Kingdom in 1949. It started the first professional journal, Ergonomics, in 1957. Currently, there are well over 5,000 members organized in 20 different technical groups. PRESENT TRENDS Practitioners of methods, standards, and work design have come to realize that such factors as age, health and well-being, physical size and strength, training attitudes, job satisfaction, and motivation response have a direct bearing on productivity. Today’s practitioners must use the “humane” approach. They must be well versed in the study of human behavior and accomplished in the art of communication. They must also be good listeners, respecting the ideas and thinking of others, particularly the worker at the bench. Today, there is a greater intrusion by the government in the regulation of methods, standards, and work design. For example, military equipment contractors and subcontractors are under increased pressure to document direct labor standards as a result of MIL-STD 1567A Similarly, in the area of work design, Congress passed the OSH Act establishing the National Institute for Occupational Safety and Health (NIOSH), are search agency for developing guidelines and standards for worker health and safety, and the Occupational Safety and Health Administration (OSHA) an enforcement agency to maintain these standards.