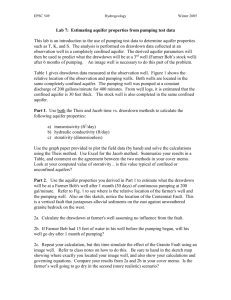

Well Development

advertisement

Well Development and Efficiency Groundwater Hydraulics Daene C. McKinney Introduction • Well Drilling – – – – Augers Cable Tool Rotary Mud • Well Completion – – – – Unconsolidated formations Consolidated Formations Well Screens Gravel Packs • Well Development – – – – – Well Drawdown Well Losses Specific Capacity Step Drawdown Test Well Efficiency Domestic Hand Pumped Well Domestic dug well with rock curb, concrete seal, and hand pump Hand dug well in Beirut, Lebanon ~20 m depth > 1 m diameter < 500 m3/day Hand dug well in Trets, France Augers Hand-driven augers ~15 m depth > 20 cm diameter Power-driven augers ~30 m depth > 1 m diameter Power Auger • Auger drilling is done with a helical screw driven into the ground with rotation; cuttings are lifted up the borehole by the screw ~ 30 m depth < 15-90 cm diameter < 500 m3/day Drilled Well - Cable Tool • Traditional way of drilling large diameter water supply wells. • The Rig raises and drops the drill string with a heavy carbide tipped drill bit that chisels through the rock and pulverizes the materials. • 8 – 60 cm • 600 m Mud/Air Rotary • Rotary drilling relies on continuous circular motion of the bit to break rock at the bottom of the hole. • Cuttings are removed as drilling fluids circulate through the bit and up the wellbore to the surface. Drilling Mud Circulation • Lift cuttings from the borehole and carry to pit; • Cuttings drop out in the pit; • Length of drill pipe is added; • Film on the borehole wall prevents caving; • Seals borehole wall to reduce fluid loss; • Cools and cleans bit; and • Lubricates bit, bearings, mud pump and drill pipe . Well Completion • After drilling, must “complete” the well – Placement of casing – Placement of well screen – Placement of gravel packing – Open hole Well Construction • Well casing – Lining to maintain open hole – Seals out other water (surface, formations) – Structural support against cave-in Well in Limestone • Surface casing – From ground surface through unconsolidated upper material Placing the Pack Well Design, Completion and Development • Gravel Pack – Installed between screen and borehole wall – Allows larger screen slot sizes – Reduces fine grained sediment entering • Development – Washing fines out of the aquifer near the well – Cleaning the well with water – Air-lifting, surging, pumping, or backwashing Well Screens • May or may not be required • Proper screen improves yield • Slot size – Related to grain-size • Other considerations – Mineral content of water, presence of bacteria, and strength requirements – Excess convergence of flow Groundwater and Wells, Driscoll, 1986 Well Screens • Head loss through perforated well section – Percentage of open area (minimum 15%) – Diameter depends on well yield and aquifer thickness – Entrance velocities must be limited • • • • • • Vs = entrance velocity Q = pumping rate c = clogging cefficient Ds = screen diameter Ls = screen length P = Percent open area Well Development • After completion, wells are developed to increase specific capacity and improve economic life. • Remove finer materials from the formation. • Pumping • Surging • Compressed air Pumps Motor • Shallow Wells – Hand-operated – Turbine – Centrifugal (shallow, high volume) • Deep Wells Motor – turbine, submersible turbine submersible Well Diameter vs Pumping Rate (max 5 ft/sec in casing) Well Casing (in. ID) 6 8 10 12 14 16 20 24 30 Well Yield (gpm) 100 175 300 700 1000 1800 3000 3800 6000 Groundwater and Wells, Driscoll, 1986 Drawdown in a Well • Drawdown in a pumped well consists of two components: • Aquifer losses – – – • Head losses that occur in the aquifer where the flow is laminar Tme-dependent Vary linearly with the well discharge Well losses – – Aquifer damage during drilling and completion Turbulent friction losses adjacent to well, in the well and pipe Well Losses • Excess drawdown due to well design, well construction, or the nature of the aquifer Q æ r0 ö sw = lnç ÷ + CQ n 2pT è rw ø = BQ + CQ n æ ö lnç r0 ÷ è rw ø B= 2 pT Note UNITS! Specific Capacity • Specific capacity = Q/sw – Yield per unit of drawdown – gpm/ft, or m3/hr/m • Drawdown in the well sw = BQ + CQ 2 • Specific capacity - linear function of Q sw = B + CQ Q • Observing change in sw as Q is increased – select optimum pumping rate Step Drawdown Test • • • • • To evaluate well losses Pump a well at a low rate until drawdown stabilizes Increase pumping rate Pump until drawdown stabilizes again Repeat at least three times Step-Drawdown Test Q (m3/day) S (m) 500 1 1000 2.6 2000 8.9 2500 14.0 2750 18.6 Step Drawdown Test • Plot sw/Q vs Q • Fit straight line sw = B + CQ Q y = a0 + a1 x • Slope = a1 = C • Intercept = a0 = B Step-Drawdown Test (Example) 0.008 Q (m3/day) S (m) 0.007 500 1.14 1000 2.66 1500 5.57 2000 8.82 2500 13.54 0.002 3000 18.79 0.001 3500 23.67 0 C = 1.6x10-6 day2/m5 = 3.32 min2/m5 Severe deterioration or clogging y = 1.597E-06x + 1.307E-03 sw/Q (day/m2) 0.006 0.005 0.004 0.003 0 1000 2000 3000 Well Discharge, Q (m3/day) 4000 Losses: Formation, Well, Total Well Efficiency • Specific capacity = Q/s – Relationship between drawdown and discharge of a well • Describes productivity of aquifer and well • Specific capacity decreases with – Time – Increasing Q • Well efficiency = ratio of aquifer loss to total loss Summary • Well Drilling – – – – Augers Cable Tool Rotary Mud • Well Completion – – – – Unconsolidated formations Consolidated Formations Well Screens Gravel Packs • Well Development – – – – – Well Drawdown Well Losses Specific Capacity Step Drawdown Test Well Efficiency