Methodological overview: Freely available R&D

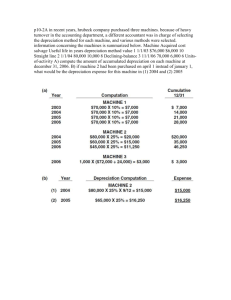

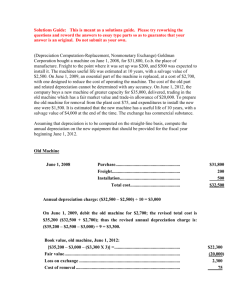

advertisement

R&D as a Value Creating Asset Emma Edworthy Gavin Wallis Methodological Overview: Linking Tables • UK Business R&D linking Tables: BERD MINUS Capital expenditure on land and buildings and plant and machinery PLUS Acquisition of R&D to be used as input in R&D production PLUS Capital Services Methodological overview: Freely available R&D • Canberra II group made the following recommendation: ‘In principle, freely available R&D should not be included as Capital formation, but in practice it may not be possible to exclude it. The assumption is that including freely available R&D would not lead to significant error’. • On the basis that it is too difficult to separate it out, the UK are going to include all freely disseminated R&D. Methodological overview: Double Counting • Computer software: software development outside the computer industry is likely to be picked up in the BERD and own account software numbers • GFCF • 1. Estimates from surveys collecting data on GFCF (CAPEX, ABI) will include some intellectual property • 2. Not all expenditure by companies in the R&D industry will result in intellectual property. They will also invest in furniture and fittings etc. Current Price GFCF Total expenditure on R&D (Frascati Manual based) = Current expenditure on R&D (labour costs etc.) Current expenditure on R&D (labour costs etc.) + + R&D related expenditure on other assets (Plant and machinery, purchased software etc.) R&D GFCF Derived estimate of capital service flows from other asset classes* addition of R&D GFCF R&D related expenditure on other assets (Plant and machinery, purchased software etc.) + estimation = = National Accounts GFCF estimation National Account capital stock Capital consumption non-R&D related expenditure on assets (Plant and machinery, software etc.) GDP * Can either be derived as consumption of fixed capital COFC (capital consumption) plus a normal return on capital used or direct capital services estimates Current Price GFCF • We use three different methods for calculating the capital service flows from other asset classes: • Method 1: Consumption of Fixed capital (COFC) plus an assumed return GFCFt Ct I at I at COFCat Rat a a a a • Method 2: Capital services estimated using rentals GFCFt Ct I at I at CSat a a a • COFCat K at a CSat K at rat Method 3: Capital services estimated using capital services growth rates GFCFt Ct I at I at CSat a a a CSa 0 K a 0 ra 0 CSat 1 CSat g at t 1, 2, Current Price GFCF • Method one is a proxy estimate of Capital services • In methods two and three the capital service flow from the asset used in R&D is measured directly. • Capital services growth rate is a much more common output of statistical offices than estimated rental rates. • UK currently publishes capital services growth rates annually, but not rentals. • Methods two and three are preferred on theoretical grounds, as they directly measure capital services flows. Which is best? Constant Price GFCF Data sources used: R&D component Proxied by Source Wages and salaries •Index of earnings of ASHE science and technology Professionals •Index of average earnings of technicians •Index of average earnings of Administrative occupations Other current (materials etc) PPI (input) materials and fuels purchased by manufacturing excluding FBTP PPI Capital Separate index for plant and machinery and land and buildings National Accounts capital stock deflators Constant Price GFCF 120 115 110 105 GDP deflator R&D deflator 100 95 90 1998 1999 2000 2001 2002 2003 year Depreciation rate In calculating an R&D stock, we use the Perpetual Inventory model. K at (1 a ,t ) I a ,t 0 • We made the following assumption about the net capital stock in the initial year, assuming a steady state. Ka0 I a0 / a Depreciation rate We estimated a depreciation rate for the whole economy using econometric methods. • Looked at the impact past R&D had on productivity (GVA at market prices) • We estimated the following: GVAt G s 1... t s t s Depreciation rate Our preliminary results were run for the period 19982003: Gva_diff coefficient Standard error t L1 -0.770473 7.516772 -0.01 L2 -18.89507 10.71141 -1.76 L3 42.80761 10.53161 4.06 L4 -26.19576 10.39732 -2.52 L5 2.838254 8.741311 0.32 Depreciation Rate: • Suggest a life length mean of 5 years • Depreciation is calculated as follows: R /T Where R is the declining balance rate (equal to 2) and T is the life length mean (5) • Implies a depreciation rate of 40% • We recognise that this is a very crude method. It is just an early investigation in to a possible approach. • The approach taken could provide sensible estimates of depreciation following more development Results: Current price Business GFCF • The results from the three methods are quite similar Year MA14: Total R&D expenditure Method 1 Method 2 Method 3 2003 13.7 15.1 15.1 14.6 2002 13.1 14.9 15 14.5 2001 12.3 13.5 13.4 13.1 2000 11.5 12.4 12.5 12.1 1999 11.3 12.5 12.7 12.3 1998 10.1 10.9 11.1 10.8 1997 9.5 11.3 10.4 11.2 Results: Business R&D Capital stock 15% Depreciation Year Method Method Method 1 2 3 64.2 64.5 62.7 2003 57.8 58 56.7 2002 50.4 50.1 49.6 2001 43.5 43.9 42.9 2000 36.7 37 36.3 1999 28.4 28.7 28.2 1998 20.5 20.6 20.5 1997 12 12.1 12.1 1996 40% Depreciation Year Method Method Method 1 2 3 34.9 35.1 33.9 2003 33.1 33.3 32.3 2002 30.4 30.4 29.8 2001 28.3 28.5 27.9 2000 26.5 26.7 26.1 1999 23.2 23.5 23.1 1998 20.5 20.7 20.5 1997 17 17.1 17.1 1996 Preliminary Productivity Analysis: Firm Level yit a 1 nit 2 kT ,it 3 k R ,it 4 D eit Where: y: value added n: labour kT ,it : tangible capital a: impact of external knowledge on the firm’s productivity k R ,it : R&D e: error term D: Service industry dummy Preliminary Productivity Analysis: Employment 0.71*** (40) Tangible Capital 0.25*** (19) R&D Capital stock (RD) 0.08*** (11) Services dummy 0.17*** (4.4) Services*RD 0.01*** (3.2) Patent Dummy 0.08*** (4.0) Domestic Dummy 0.05** (2.5) Patent dummy*RD 0.0 (0.05) UK dummy*RD 0.005** (2.01) US dummy*RD 0.007** (2.23) Japan dummy*RD 0.01 (1.38) EU dummy*RD 0.00 (-1.82) *** significant at 1% level ** significant at 5% level * Significant at 10% level Preliminary Productivity Analysis: • Our analysis considers the link between the level of value added and the level of R&D • By estimating the Cobb Douglas production function we obtained a coefficient on R&D that represents the elasticity of R&D with respect to TFP i.e. the % change in productivity for a % change in R&D • The estimates of R&D elasticity is 0.08. This implies that a 10% increase in BERD is associated with a productivity increase of 0.8%. • Average difference between the impact of services and manufacturing on productivity. Services firms are on average more productive. Preliminary Productivity Analysis: • Interacting services and the R&D capital stock suggested that an increase in R&D capital stock leads to a bigger increase in productivity for Services than manufacturing. • Sector breakdown: An increase in the R&D capital stock in services and primary industries leads to a larger increase in productivity than manufacturing. • Whereas construction and energy have a negative impact compared to manufacturing. Preliminary Productivity Analysis: • The addition of dummies for patented industries and foreign ownership showed that patented firms and UK firms add more to productivity. • R&D coefficient on R&D capital stock still remains significant after the addition of the patent dummy. • UK owned, manufacturing firms in the patent industry add most to productivity. • However, interacting the patent and foreign owned dummies with the R&D capital stock showed that there was no additional affect from being a UK firm or in a patent industry. • UK owned firms and US firms have an additional effect from an increase in the R&D capital stock on productivity over and above the rest of the world.