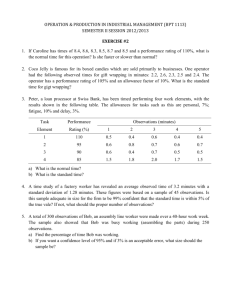

PPCE - solved questions with answer

advertisement