Introduction to presentation - 5 min

advertisement

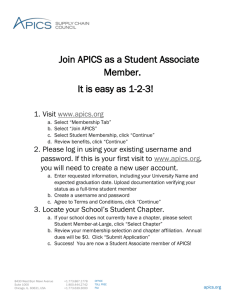

Wednesday, April 6th Central Jersey APICS presents: Project Management Death March Projects John H. Capron, CPIM President, Mid-Hudson Chapter of APICS "A Death March Project is one for which an unbiased, objective risk assessment (includes an assessment of technical risks, personal risks, legal risks, political risks, etc.) determines that the likelihood of failure is >50%." With average project success rates of 39%, Death March Projects are probably more the norm than the exception. You can expect to take away from this presentation an understanding of what a death march project looks like, and what you can do to survive it, or to avoid it all together. You will learn: The profile of a death march project How to know you are getting into a death march project Reasons for a death march project Why do people get involved with a death march project Project politics Who the important players are The losing battle for the project manager Project estimates Picking the project team Project survival methods & tools Some words of wisdom for project managers This presentation is for: Project Managers and anyone impacted by a project, whether a project team member, a future project team member, or the recipient of a project to be delivered anyone currently funding a project The Hotel Somerset – 110 Davidson Avenue – Somerset, NJ 732 560-0500 5:30 – 6:15 6:15 – 6:30 6:30 – 7:15 7:15 – 8:15 Registration & Networking – Complimentary Wine & Beer President’s Welcome, Chapter Business Dinner & Discussion – Plated Dinner Presentation & Discussion With Reservations: $40; $25 Full-Time Students Register at: www.APICS-CJer.org John is a retired operations professional, having built a 43 year career in manufacturing, planning, IT development, and consulting. He has been a Technical Team Leader, Development Manager and ERP Senior Consultant for the IBM Corporation, an ERP Senior Consultant for Keane, NYNEX, Origin, and Philips. He has also held the following positions at Philips: Materials Manager, Systems Operations Planning Analyst, Production Control Supervisor, Manufacturing Supervisor, and Production Data Analyst. John’s real introduction to the world of manufacturing began with Georgia-Pacific and Kraft Foods. Along the way, he became quite proficient in production & inventory management, but also recognized that he needed to become highly capable in enabling methodologies & technologies as they became mainstream. He has a solid understanding of ERP, Project Management, Requirements Engineering, Business Process Design, Software Development, Mind Mapping, SEO, Web Design, S&OP, and Structured Analysis.