Recap

advertisement

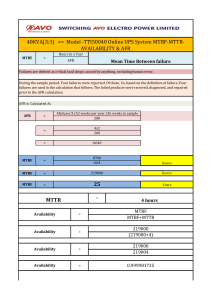

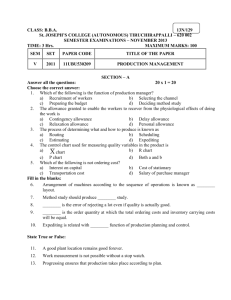

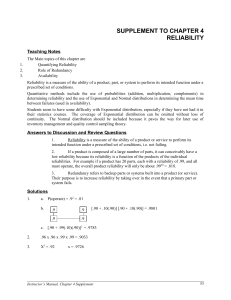

Recap Chapter 4 and Chapter 7 CHAPTER 4 What Does Product & Service Design Do? • Translate customer wants and needs into product and service requirements • Refine existing products and services • Develop new products and services • Formulate quality goals • Formulate cost targets • Construct and test prototypes • Document specifications • Translate product and service specifications into process specifications Idea Generation • Supply chain-based • Competitor-based – Reverse engineering: Dismantling and inspecting a competitor’s product to discover product improvements • Research-based – Basic research – Applied research – Development Design Considerations • Legal Factors (Mandatory) – Product liability: The responsibility a manufacturer has for any injuries or damages caused by as faulty product • • • • Ethics Human Factors Cultural Factors Environmental Factors: sustainability – 3R: reduce, reuse, recycle • Life Stage • Standardization • Mass Customerization – Delayed differentiation and Modular design • Quality Function Deployment/The House of Quality • • An approach that integrates the “voice of the customer” into both product and service development The purpose is to ensure that customer requirements are factored into every aspect of the process • Kano Model – Basic quality – Performance quality – Excitement quality Designing (products) for Production 1. Concurrent engineering 2. Computer-Assisted Design (CAD) 3. Production requirements a. Design For Manufacturing (DFM) b. Design For Assembly (DFA) 4. Component commonality Reliability • Reliability is expressed as a probability: – (Single Component Reliability) The probability that a part, or a single component works. – The probability that the product or system will function when activated – The probability that the product or system will function for a given length of time What is this system’s reliability? .85+(1-.85)*(.8+(1-.8)*.75) .75 .80 .80 .70 .95 .85 .90 .95+(1-.95)*.8 1-((1-.75)*(1-.8)*(1-.85)) .99 .9925 .99*.9925*.97 .9531 .9+(1-.9)*.7 .97 Exponential Distribution Exponential Distribution – Formula P (no failure before T ) e T / MTBF where e 2.7183... T Length of service before failure MTBF Mean time between failures Availability • The fraction of time a piece of equipment is expected to be available for operation Availabili ty MTBF MTBF MTR where MTBF Mean time between failures MTR Mean time to repair CHAPTER 7 Quality of Work Life • Important aspects of quality of work life: – Working conditions • Physical • Psychological – Compensation • Time-based systems • Output-based systems – Incentive programs • Knowledge-based systems – Job Design Behavioral Approaches to Job Design • Job Enlargement – Giving a worker a larger portion of the total task by horizontal loading • Job Enrichment – Increasing responsibility for planning and coordination tasks, by vertical loading • Job Rotation – Workers periodically exchange jobs Observed Time x OT i n where OT Observed time x i Sum of recorded times n Number of observatio ns Normal Time NT x j PR j where NT Normal time x j Average time for element j PR j Performanc e rating for element j Assumes that performance ratings are made on an elementby-element basis Standard Time ST NT AF where ST Standard time AF Allowance factor and AFjob 1 A AFday 1 1 A A Allowance percentage based on job time A Allowance percentage based on workday • Suppose a worker can do k cycles per day. ST Example (from Problem Solving) • Ahe worker’s time averaged 1.9 minutes per cycle, and the worker was given a rating of 120 percent. Assuming an allowance factor of 12 percent of workday, determine the standard time for this job. • Solution: ST = NT*AF=(1.9*120%)*(1/(1-12%))=2.59 RECALL FROM CHAPTER 1 Supply and Demand Sales & Marketing Operations & Supply Chains Supply > Demand Wasteful Costly Supply < Demand Opportunity Loss Customer Dissatisfaction Supply = Demand Ideal 4 Sources of Process Variation • Variety of goods or services being offered – The greater the variety of goods and services offered, the greater the variation in production or service requirements. • Structural variation in demand – These are generally predictable (seasonal variation or seasonality, e.g., swimwear, warm clothes, Christmas, tourist seasons, school supplies). – They are important for capacity planning • Random variation – Natural variation that is present in all processes (e.g., random demand etc.). Generally, it cannot be influenced by managers. • Assignable variation – Variation that has identifiable sources. (e.g., defective inputs, incorrect work methods, equipment etc.) – This type of variation can be reduced, or eliminated, by analysis and corrective action. Case Study • Apple Readies a Big Bet on Big-Screen Phones • What design considerations have Apple put into their new product? – – – – – Legal/ethical Human factors Cultural factors Environmental factors Standardization/Customerization • How big is the bet? – Quantity of the new products.