Apresentação do PowerPoint

advertisement

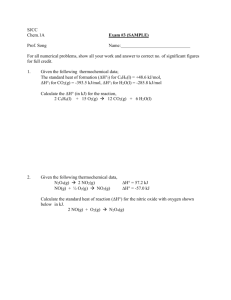

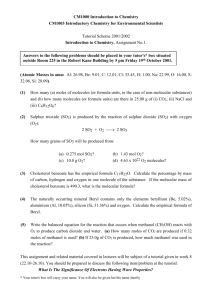

Green Methanol from the Hydrogenation of Carbon Dioxide Claudio J. A. Mota1,2 cmota@iq.ufrj.br 1Federal University of Rio de Janeiro – Institute and School of Chemistry, Brazil 2INCT Energy & Environment, UFRJ, Brazil Chemistry and Fuels Wood Until 1700 Coal 1700-1900 Petroleum 1900 - today CO2 Concentration in the Atmosphere CO2 Net Emissions in 2011: 16.1 Billions Mton [CO2 atmosphere concentration]: 400 ppm (2013) ~ 40% increase 1 Pg = 1 Petagram = 1x1015g = 1 Billion metric tons = 1 Gigaton 278 ppm 1 Kg Carbon (C) = 3.67 Kg Carbon Dioxide (CO2) (1785) – Industrial Revolution starts Source: Global Carbon Project 2014 CO2 Concentration in the Atmosphere Glycerol C&EN 2009, vol 87, number 22, pages16-17 Glycerol O OH HO "H+" OH + O O + H2O OH C. X. da Silva, V. L. C. Gonçalves, C. J. A Mota Green Chem. 2009, 11, 38-41 6 2.5 4 3 Gasoline A Gasoline C 2 1 Octane number increment Gum (mg/mL) 5 2.0 Gasoline A Gasoline C 1.5 1.0 0.5 0.0 0 0 1 2 3 4 Ketal (%) 5 6 0 1 2 3 4 5 Ketal (%) Mota, C. J. A., Silva, C. X. A.; Rosenbach, N.; Costa, J. Silva, F.. Energy Fuels 2010, 24, 2733 Glycerol OH OH HO OH + HO EtOH O "H+" + O HO OH + H2O OH O O O + HO O Flow Properties ASTM – D 97 SAMPLE Cloud (°C) Freezing (°C) Pour (°C) B 100 (PALM) 18 15 18 B100 + 0.1 % ETHERS 15 12 15 B100 + 0.5 % ETHERS 14 11 14 B100 + 1 % ETHERS 14 11 14 Biodiesel O O R1 R1 O OCH3 OH O R2 O O + 3 CH3OH HO KOH R2 OCH3 O OH + B7 - 2014 glycerol O R3 O vegetable oil R3 OCH3 Biodiesel A. L. Lima, A. Mbengue, M. Guarnier, R. A. Sangil, C. M. Ronconi, Claudio J. A. Mota. Catal. Today 2014, 226, 210-216. Biodiesel RCO2H RCO2CH3 + + H + H H OH- - OH Triglyceride - OH H+ H+ 3 RCO2CH3 H+ Concept of CO2 Utilization http://co2chem.co.uk/ “Anthropogenic Chemical Carbon Cycle" , George A. Olah et al, JACS 2011,133,12881 Industrial Initiatives of CO2 Hydrogenation to Methanol Mitsui Chemicals | Osaka, Japan Pilot Plant - 100 tonnes MeOH/yr Cu/ZnO promoted catalyst Packed bed (25 kg catalyst) CO2 as feedstock H2 from Water Photolysis Catalyst life: 4,500 h Source: Mitsui Chemicals – Information Brochure Carbon Recycling International | Iceland Commercial Plant since 2011 5 MM Liters/yr of methanol CO2 Reclaim: 4.5 MM Tonn/yr H2 from water electrolysis using geothermal energy Source: Carbon Recycling International Importance of Methanol Production of biodiesel Production of formaldehyde Production of acetic acid Production of dimethyl ether (DME) World production around 50 millions tonnes per year Fonte: Methanol Institute Production of resins and plastics MTH olefins and hydrocarbons (fuels) World Methanol Industry US$ 36 billions/year with 100 thousand jobs Fonte: Methanol Institute Thermodynamics Considerations Methanol formation: CO + 2H2 CH3-OH ΔHO50Bar,298K = - 90.6 kJ/mol CO2 + 3H2 ΔHO50Bar,298K = - 49.4 kJ/mol CH3-OH + H2O Reverse WGS as a side reaction: CO2 + 3H2 CO + H2O ΔHO50Bar,298K = + 41.1 kJ/mol Methanol synthesis is exothermic Reduction of molecularity (3:1 for CO/H2; 4:2 for CO2/H2) Thermodynamics: Low temperature and high pressure favor the methanol synthesis Green Methanol Plant in Brazil Bioethanol Economy C6H12O6 yeast 2 C2H5OH + 2 CO2 Methanol forma on: CO2 + 3H2 CH3-OH + H2O Initial studies ΔHO50Bar,298K = - 49.43 kJ/mol Cu/Zn/Al 50/40/10 molar ratio Weight: 500 mg Reverse WGS as a side reac on: Catalyst Activation: 3-steps reduction: 10%H2/N2 (1) 140oC for 5 h; (2) Raised to 270oC in 2 h (3) 270oC for 2 h Reaction Conditions: Temperature: 230, 250, 270oC Pressure: 15, 30, 50 bar WHSV: 10 h-1 CO2/H2: 1/3 molar ratio TOS: 20 h CO2 + H2 CO + H2O ΔHO50Bar,298K = + 41.12 kJ/mol Initial Studies Cu/Zn/Al (50/40/10 mol%) WHSV = 10 h-1 ; TOS = 20 h ; H2:CO2 = 3:1 20 100 18 90 70 bar 16 80 50 bar 14 70 Selectivity (%) CO2 Conversion (%) 270 oC 12 10 8 6 30 bar 60 50 40 30 4 20 2 10 0 70 50 Pressure (bar) 30 0 CH3OH CO Products CH4 Cu/Zn/Al (50/40/10 mol%) WHSV = 10 h-1 ; TOS = 20 h ; H2:CO2 = 3:1 MeOH Yield (gCH3OH/kg.h) 1000 50 bar CuZnAl 900 30 bar CuZnAl 800 15 bar CuZnAl 700 Mitsui 600 500 400 300 50 bar 200 30 bar 100 15 bar 0 220 230 240 250 260 270 280 290 Temperature (oC) R. S. Monteiro and C. J. A. Mota Quím. Nova 2013, 36, 1483-1490 300 Standard Catalyst Preparation Effect of Promotors 1. Metal salts water solution Cu, Zn, Al, Ce, Mg and Zr Nitrates 2. One-single pot solution pH ~ 3; heating 1000 rpm 3. Co-precipitation (pH = 6-7) 1M NaOH; dropwise T = 60- 70oC; aged 60 min pH = 3 4. Filtration/Washing 5. Drying T = 160oC; 10oC/min 18 hrs. 6. Calcination T = 600oC; 10oC/min 2h 7. Crushing and Sieving Cu/Zn/Promotors (50/40/10 mol%) pH = 5 pH = 7-8 CO2 Hydrogenation over Standard-Prepared Catalysts Methanol Yield (gMeOH/kgcat.h) 800 700 600 Equilibrium Yield (250oC, 50 bar) CuZn based catalysts – Promotion Effect 500 400 300 200 100 0 Al Zr ZrAl CeAl 230oC CeZr 250oC MgAl MgZr ZrAlGaSi CO2 Hydrogenation over Standard-Prepared Catalysts CO2 + 3H2 CH3-OH + H2O CO2 + H2 ΔHO50Bar,298K = - 49.4 kJ/mol CO + H2O ΔHO50Bar,298K = + 41.1 kJ/mol CuZn based catalysts CO2 Conversion (mol.%) 25 100 40 90 20 CO Selectivity (mol.%) CH3OH Selectivity (mol.%) 35 80 30 70 15 25 60 50 10 20 40 15 30 10 5 20 5 10 0 0 230oC ZrAl 250oC ZrAlGaSi 0 230oC ZrAl 250oC ZrAlGaSi 230oC 250oC ZrAl ZrAlGaSi Activity/Structure Correlation BET Area CuZn based catalysts 700 ZrAlGaSi 600 ZrAl MeoH Yield 500 CeAl 400 CeZr MgAl 300 Zr MgZr 200 R² = 0.894 100 0 0 10 20 30 40 BET Surface Area (m2.g-1) 50 60 Activity/Structure Correlation TPR Profile CuZn based catalysts 300oC 416oC ZrAlGaSi • Catalyst activation: 270oC ZrAl • CuO Cuo (> 300oC) • CuO surface reduction under CeAl reaction conditons. • Better MeOH yield on catalysts Al with lower temperature of reduction CuO 100 150 200 250 300 350 400 Temperature (oC) 450 500 550 600 • Promoters allow CuO reduction at lower temperatures Activity/Structure Correlation DRX CuZn based catalysts ZnO (100) CuO (111) ZnO (101) ZnO (002) CuO (111) Amorphous phase or tiny particles?? ZrAlGaSi ZrAl SnAl CeAl MgAl Al 30 31 32 33 34 35 36 2 Theta (O) 37 38 39 40 Improved Catalyst Preparation 1. Metal salts water solution Cu, Zn, Al, Ce and Zr Nitrates Reaction Conditions: 250oC; 50 bar; 10 h-1 2. One-single pot solution pH ~ 3; heating Cu/Zn/Zr/Al 1000 rpm IMP 3. Co-precipitation (pH = 6-7) 1M Na2CO3; dropwise T = 60- 70oC; aged 60 min 4. Filtration/Washing STD 5. Drying T= 160oC; 10oC/min 18 hrs. 6. Calcination T= 600oC; 10oC/min (STD) T = 380 oC; 10oC/min (IMP) MeOH Yields – Cu/Zn/Zr/Al: 7. Crushing and Sieving IMP: > 700 gMeOH/Kgcat.h STD: > 500 gMeOH/Kgcat.h Improved Catalyst Preparation Methanol Selectivity Methanol Yield Cu/Zn/Zr/Al Cu/Zn/Zr/Al Improved Catalyst Preparation CO Selectivity Catalyst BET Area (m2/g) CuZnZrAl_IMP 78 CuZnZrAlGaSi 54 CuZnAl_STD 31 Cu/Zn/Zr/Al Summary of the Results T = 2500C, P = 50 bar, 10 h-1, TOS 8 h Composition Methanol Yield (gMeOH.kgcat-1.h-1) % Equilibrium Yield Mitsui Reference* 721 100 Cu/Zn/Zr/Al_IMP 720 100 Cu/Zn/Zr/Al_STD 510 70 Cu/Zn/Ce/Al_STD 480 67 Cu/Zn/Mg/Al_STD 370 51 Cu/Zn/Ce/Zr_STD 350 48 Cu/Zn/Zr_STD 320 44 Cu/Zn/Mg/Zr_STD 280 39 Cu/Zn/Al_STD 180 25 * K. Ushikoshi, K. Mori. T. Kubota. T. Watanabe and M. Saito, Appl. Organometal. Chem 2000, 14, 819 People Financing Conselho Nacional de Desenvolvimento Científico e Tecnológico INCT ENERGIA & AM BIENTE Give Nature a Chance Forthcoming events in Rio 2016 International Zeolite Conference (IZC) 2017 Acid Base Catalysis (ABC) 2017 IUPAC Congress (São Paulo) 2018 ICCDU - XVI Thermodynamic limitations 1600 70 bar Equilibrium MeOH Yield (gCH3OH/kg.h) 1400 50 bar Equilibrium 1200 30 bar Equilibrium 15 bar Equilibrium 1000 800 600 400 200 0 200 210 220 230 240 250 260 Temperature (oC) 270 280 290 300 W.-J. Sien, K.-W. Ju, H.-S. Choi, K.-W. Lee, Korean J Chem Eng 2000,17, 210-216 () Mechanistic Studies Lowest-energy pathway: CO2* → HCOO* → HCOOH* → CH3O2* → CH2O* → CH3O* → CH3OH* L. C. Grabow and M. Mavrikakis, ACS Catalysis 1 (2011) 365