Course File

advertisement

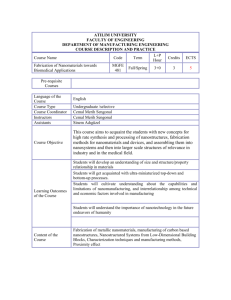

ATILIM UNIVERSITY FACULTY OF ENGINEERING DEPARTMENT OF MANUFACTURING ENGINEERING COURSE DESCRIPTION AND PRACTICE L+P Course Name Code Term Credits Hour MGFE Machine Theory 5 2+2 3.0 305 Pre-requisite Courses Language of the Course Course Type Course Coordinator Instructors Assistants Course Objective ECTS 5.5 MFGE 204 – Engineering Mechanics II English Compulsory Besim Baranoğlu Besim Baranoğlu Hakan Kalkan The aim of this course is to introduce students with fundamentals of mechanisms and their kinematic and force analysis. Ability to identify a mechanism, determine the degree of freedom Perform position, velocity and acceleration analysis of planar mechanisms Learning Outcomes of the Course Have vision in design of special mechanisms; like quick-return, dwell, two-three position mechanisms and locking mechanisms Design and analyze gear trains Perform static and dynamic force analysis on mechanisms Content of the Course Introduction to mechanisms: basic concepts, mobility, basic types of mechanisms. Position, velocity and acceleration analysis of linkages. Cam mechanisms. Gear trains. Static and dynamic force analysis of mechanisms. Introduction to vibrations. WEEKLY SCHEDULE AND PRE-STUDY PAGES Topics Pre-study Pages Week 1 Introduction and Basic Concepts 2 Definition of Joint, Link, Kinematic Chain 3 Degree of Freedom of Mechanisms 4 Further Points on DOF of Mechanisms, Kinematic Inversion, Grübler’s Equation and Enumeration of Mechanisms 5 Linkage synthesis: design of linkages for two and three positions, quick-return. Design of dyads for driving the mechanisms 6 Kinematic Analysis of Mechanisms, Loop Closure Equations 7 Position Analysis of Mechanisms (Solution Techniques for Loop Closure Equations) Velocity and Acceleration Analysis of 8 Mechanisms 9 Cam Mechanisms 10 Gear Trains, Simple Gear Trains 11 Planetary Gear Trains, Bevel Gears 12 Four-Link Mechanisms 13 Force Analysis in Machinery, Static Force Analysis 14 Force Analysis in Machinery, Dynamic Force Analysis, Vibrations 15 Final exam period 16 Final exam period SOURCES Course Book Other sources [1] Söylemez Eres, Mechanisms, 3rd edition, 1999, METU Publications [2] Norton Robert L., Design of Machinery,3rd edition, 2004, ISBN:007123671-6 EVALUATION SYSTEM IN-TERM STUDIES Mid-terms Quizzes Assignment Participation Lab work (Project) TOTAL CONTRIBUTION OF IN-TERM STUDIES TO OVERALL GRADE CONTRIBUTION OF FINAL EXAMINATION TO OVERALL GRADE TOTAL QUANTITY 2 0 5 0 1 PERCENTAGE 40 0 10 0 20 70 1 30 Course Category Mathematics and Basic Science Engineering Expertise/Skill Courses Engineering Design 100 20% 40% 0 40% CORRELATION BETWEEN COURSE LEARNING OUTCOMES AND PROGRAM COMPETENCIES Percentage No Program Competencies 1 2 3 4 5 An ability to apply knowledge in mathematics and basic sciences and 1 x computational skills to solve manufacturing engineering problems 2 3 4 5 6 7 An ability to define and analyze issues related with manufacturing technologies An ability to develop a solution based approach and a model for an engineering problem and design and manage an experiment An ability to design a comprehensive manufacturing system based on creative utilization of fundamental engineering principles while fulfilling sustainability in environment and manufacturability and economic constraints An ability to chose and use modern technologies and engineering tools for manufacturing engineering applications An ability to utilize information technologies efficiently to acquire datum and analyze critically, articulate the outcome and make decision accordingly An ability to attain self-confidence and necessary organizational work skills to participate in multi-diciplinary and interdiciplinary teams as well as act individually x x x x x x 8 An ability to attain efficient communication skills in Turkish and English x both verbally and orally 9 An ability to reach knowledge and to attain life-long learning and selfimprovement skills, to follow recent advances in science and technology 10 An awareness and responsibility about professional, legal, ethical and x social issues in manufacturing engineering 11 12 x An awareness about solution focused project and risk management, enterpreneurship, innovative and sustainable development An understanding on the effects of engineering applications on health, social and legal aspects at universal and local level during decision making process x x TABLE OF ECTS / WORKLOAD Activities Course Duration (Including the exam week: 16x Total course hours) Hours for off-the-classroom study (Pre-study, practice) Assignments Mid-terms Final examination Total Work Load Total Work Load / 30 ECTS Credit of the Course QUANTITY Duration Total (Hour) Workload 16 4 64 16 5 2 1 3 8 3 3 48 40 6 3 161 5.4 5.5