Chapter 4 - WordPress.com

advertisement

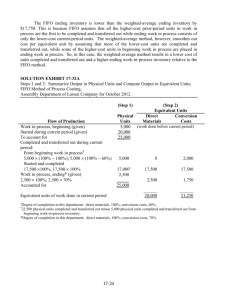

Chapter 4 System Design—Process Costing Learning Objectives LO1. LO2. LO3. LO4. LO5. LO6. LO7. LO8. LO9. Record the flow of materials, labor, and overhead through a process costing system. Compute the equivalent units of production using the weighted-average method. Prepare a quantity schedule using the weighted-average method. Compute the costs per equivalent unit using the weighted-average method. Prepare a cost reconciliation using the weighted-average method. (Appendix 4A) Compute the equivalent units of production using the FIFO method. (Appendix 4A) Prepare a quantity schedule using the FIFO method. (Appendix 4A) Compute the costs per equivalent unit using the FIFO method. (Appendix 4A) Prepare a cost reconciliation using the FIFO method. New in this Edition • Additional simple exercises have been created. Chapter Overview A. Job-Order Costing vs. Process Costing. Process costing is used in industries that produce homogenous products such as bricks, flour, and cement on a continuous basis. 1. Similarities between job-order and process costing. Job-order and process costing systems share some characteristics: a. Both systems have the same basic purpose—to assign material, labor, and overhead cost to products. b. Both systems use the same basic manufacturing accounts: Manufacturing Overhead, Raw Materials, Work In Process, and Finished Goods. c. The flow of costs through the manufacturing accounts is basically the same. 2. Differences between job-order and process costing. The differences between job-order and process costing occur because the flow of units in a process costing system is more or less continuous and the units are essentially indistinguishable from one another. Under process costing: a. A single homogenous product is produced on a continuous basis over a long period of time. This differs from job-order costing in which many different products may be produced in a single period. b. Costs in process costing are accumulated by department, rather than by individual job. c. The department production report is the key document in process costing, showing the accumulation and disposition of cost. In job-order costing, the job-cost sheet is the key document. B. Overview of Process Costing. (Exercises 4-1 and 4-10.) Manufacturing costs are accumulated in processing departments in a process costing system. A processing department is any location in the organization where work is performed on a product and where materials, labor, and overhead costs are added to the product. Processing departments should also have two other features. First, the activity performed in the processing department should be essentially the same for all units that pass through the department. Second, the output of the department should be homogeneous. In process costing, the average cost of processing units for a period is assigned to each unit passing through the department. Two process costing methods are illustrated in the text—the weighted-average method and the FIFO method. While the FIFO method provides more current cost data for decision-making and performance evaluation purposes, it is more difficult for students to grasp. For that reason, the FIFO method is covered in an appendix. C. Equivalent Units of Product. (Exercises 4-2, 4-11, 4-13, and 4-17.) In order to calculate the average cost per unit, the total number of units must be determined. Partially completed units pose a difficulty that is overcome using the concept of equivalent units. Equivalent units are the equivalent, in terms of completed units, of partially completed units. The formula for computing equivalent units is: Number of Equivalent partially completed Percentage units completion units Equivalent units are the number of complete, whole units one could obtain from the materials and effort contained in partially completed units. Under the weighted-average method, the equivalent units for a particular cost category (e.g., materials or conversion cost) is computed by adding together the number of units completed and transferred out to the next department during the period and the equivalent units in the ending work in process inventory in the department. Equivalent Units transferred to Equivalent units units of the next department in ending work in production or to finished goods process inventory D. Production Report. The purpose of a production report is to summarize all of the activity that takes place in a department's work in process account for a period. A production report consists of three parts: • A quantity schedule and a computation of equivalent units. • A computation of costs per equivalent unit. • A reconciliation of all cost flows into and out of the department during the period. E. Production Report: Weighted-Average Method. (Exercise 4-13 followed by Exercise 4-14.) Emphasize that the weighted-average method does not attempt to separate units in the beginning inventory from units started during the current period. Costs and units from beginning inventory are blended together with costs and units from the current period. 1. Quantity Schedule and Equivalent Units. (Exercises 4-2, 4-4, and 4-11.) The first step in preparing a production report is to prepare a quantity schedule, which shows the physical flow of units through the department. This schedule allows managers to see at glance how many units moved through the department during the period. Using the quantity schedule, the equivalent units can be easily computed. 2. Costs per Equivalent Unit. (Exercises 4-6 and 4-13.) The second step in preparing a production report is to calculate the costs per equivalent unit. The cost per equivalent unit is computed for a particular cost category (i.e., materials, labor, overhead, or conversion) by dividing its total cost by its total equivalent units. Note that under the weighted-average method the costs include both the costs already in beginning inventory as well as the costs added by the department during the current period. 3. Cost Reconciliation. (Exercise 4-7.) The third step in preparing a production report is to prepare a cost reconciliation. The purpose of a cost reconciliation is to show how the costs from beginning work in process inventory and costs that have been added during the period are accounted for. a. Costs come into the department from units in beginning inventory, from material, labor, and overhead costs that are added during the period, and from any units that might have been transferred in from a prior department. b. A department's costs are accounted for by showing the costs that are transferred out to the next department (or to finished goods) and by specifying the costs that remain in the ending work in process inventory. F. Operation Costing. The costing systems discussed in Chapters 3 and 4 represent the two ends of a continuum. On one end is job-order costing and on the other is process costing. Between the two extremes, there are many “hybrid” systems. Operation costing is an example of such a hybrid system. It is used in situations where products have some common as well as individual characteristics. TVs, for example, have some common characteristics in that all models must be assembled and tested following the same basic steps. However, each model has different components with different costs. The costs of the components (materials) would be charged to a batch of a particular model individually, as in job-order costing, but the conversion costs may be assigned using process costing. G. FIFO Method (Appendix 4A). (Exercise 4-15 followed by Exercise 4-16.) The FIFO method segregates the units and costs in the beginning inventory from the units and costs of the current period. 1. Quantity Schedule. (Exercises 4-5 and 4-12.) The quantity schedule prepared under the FIFO method is identical to that prepared under the weighted-average method, except that the “units transferred out” are separated into those units that came from beginning inventory and those units that were started and completed this period. 2. Equivalent Units. (Exercises 4-3 and 4-12.) The FIFO method differs from the weightedaverage method for computation of equivalent units in two ways. a. First, under the FIFO method the “units transferred out” figure is split between units completed from the beginning inventory and units started and completed during the current period. b. Second, the equivalent units refers to just the equivalent units for the work performed during the current period. The equivalent units under the FIFO method consist of three amounts: the work needed to complete the units in the beginning inventory; the work expended on the units started and completed during the current period; and the work expended on partially completed units in the ending inventory. c. This method is called the FIFO method because it assumes that the units in beginning inventory are completed and transferred out before any new units are started. The costs of beginning inventory are segregated from costs added during the period. d. The only difference in the equivalent unit calculations between the two methods is that the equivalent units in beginning inventory are included in the weighted-average method. Under the weighted-average method the costs already in beginning inventory will be added to the costs incurred during the period to arrive at unit costs. To be consistent we must add the equivalent units already in beginning inventory to the equivalent units for the work performed during the current period. 3. Costs per Equivalent Unit. (Exercise 4-8.) In computing costs per equivalent unit, costs associated with the beginning work in process inventory are ignored. It is assumed that the units in beginning inventory are completed and transferred to the next department before any new units are worked on. Providing that more units are transferred out than were in beginning inventory, all of the costs associated with beginning inventory will be transferred to the next department. 4. Cost Reconciliation. (Exercises 4-9 and 4-16.) As with the weighted-average method, the purpose of a cost reconciliation is to show how the costs have been charged to a department during a period and to show how these costs are accounted for. a. The “Costs to be accounted for” section of the report is the same as for the weightedaverage method. b. The “Cost accounted for” section differs from the weighted-average method in that four layers of cost are involved. These layers are (1) the cost in the beginning inventory, (2) the cost required to complete the units in the beginning inventory, (3) the cost of units started and completed during the current period, and (4) the cost of the ending work in process inventory. H. Evaluation of Weighted-Average and FIFO (Appendix 4A). The weighted-average method is simpler to learn and apply than the FIFO method, but the FIFO method is generally considered to be superior for cost control. The reason is that the FIFO method helps to isolate current performance by segregating current costs from prior period costs. The weighted-average method mixes the costs of the current period with the costs of prior periods.