1991_ExitExam_Pt

advertisement

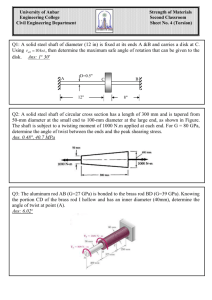

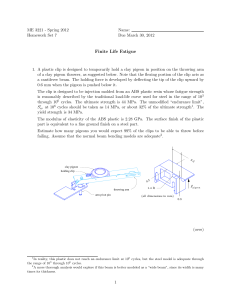

EXTRACTIVE METALLURGY I ATTEMPT 1 OR 2 (OPEN NOTES) 1. (a) The discharge of a ball mill is fed into a classifier at a rate of 600 tph containing 70 wt% solids. Upon addition to the classifier, additional water is added at a rate of 100 tph. What is the resulting pulp density, in grams per cm3 pulp? The density of solid is 2.5 g/cm3. Also calculate the volume fraction of solids in the pulp. (b) Colloidal scheelite (CaWO4: pzc=pCa 5.0) and hematite (Fe2O3: pzc=pH 6) are fully suspended in a solution which is at 25°C. The solution contains 10-4 M CaCl2 and the pH of the solution is 4. (i) Calculate the surface potentials and the thicknesses of the electrical double layer of these oxides. (ii) Estimate the potential at 10-6 cm away from the scheelite/water interface. (iii) If the zeta potential of scheelite particles is 20 mV, calculate the mobility of these particles of one micron radius in cm2/volt.s. (iv) 2. Suggest a way of separating scheelite from hematite by froth flotation. An ore consisting of 1% by wt of chalcopyrite (CuFeS2), 5% pyrite (FeS2) and 94% silica (SiO2) is to be processed first to separate the individual minerals but eventually to extract copper. The separation process will include crushing, grinding, screening, physical and chemical treatment. The ore is to be treated at a rate of 30,000 tons per year. i. Draw a flow sheet which should include the above mentioned processes. Important physical and chemical conditions and features of each unit operation should be listed. (For example, the size of units and particles, physical properties of minerals relevant to that process and physical and chemical conditions in which the process must operate.) ii. Chalcopyrite will be up-graded by froth flotation. Specify the conditions necessary to achieve this up-grading process, in particular, reference to removal of pyrite. iii. Chalcopyrite is subjected to acid leaching. Explain, using thermodynamic principles, how one could identify the maximum leaching recovery. 2 EXTRACTIVE METALLURGY II ATTEMPT 1 OR 2 (OPEN NOTES) 1. Draw a schematic and set up algebraically a heat balance for the following: Ten moles of PbO at 500°C, 20 moles of C at 200°C, and 50 moles of air at 100°C. Enter a reactor to produce ten moles of liquid Pb at 600°C and top gas composed of CO and CO2 at 1000°C. Define all terms used. 2. An Au-Cu alloy is to be refined by blowing pure oxygen through the molten alloy. Calculate the lowest atomic percent Cu attainable by this method at 1550°K. See the attached activity data for liquid Au-Cu alloys at 1550°K. 3 PHYSICAL METALLURGY ATTEMPT 1 OR 2 (OPEN NOTES) 1. This problem is concerned with the carburization of steel which is a very important metallurgical process used by many industrial companies. a) (20%) Briefly explain the purpose for carburizing steel parts. b) (80%) You are a metallurgist working for a company that manufactures hydraulic vane pumps. Your task is to carburize a 1018 steel (0.18 wt% C) shaft which will be used in a hydraulic vane pump. Following the carburization process, the shafts will be austenitized in the region near the surface by induction heating and then quenched in water. Therefore the carbon concentration near the surface of the shaft can be correlated with the hardness of the martensite formed there. The design specifications for the shaft indicate that the surface hardness should lie between 55 and 60 on the Rockwell C scale. In addition, the case depth should be 2 mm. Note that the case depth corresponds to the distance below the surface of the shaft at which the hardness of the martensite is 50 on the Rockwell C scale. A gascarburizing process will be used such that the carbon concentration at the surface of the shaft can be maintained at any desired level. You are to specify the carbon concentration that must be maintained at the surface of the shaft during the carburization process as well as the corresponding carburization time and temperature which will produce a shaft that meets the given design specifications. 4 Assume that the carbon concentration profile of the shaft is given by the equation x Cx = Cs - (Cs - Co) erf 2 Dt where cs is the carbon concentration at the surface and co is the initial carbon concentration of the steel. Note: Activation energy for diffusion of carbon in austenite = 142 KJ/mol Diffusion constant = 20 x 10-6 m2/s j Gas Constant = 8.314 mol. k 5 2. Attached is a copy of the copper-silver phase diagram from Hansen's book. Referral to material in chapters 10 and 11 in Verhoeven's book will be helpful. Part A. Silver is added to Cu in order to obtain an age-hardening reaction and thereby strengthening the Cu. Suppose you were given the job of designing an alloy of maximum tensile properties. Outline a development research program designed to determine (1) alloy compositions, and(2) the heat-treat cycle that would achieve this objective. Give a fairly detailed description of what variables you would control and how you would arrive at optimum values. Do not consider grain-size effects. Part B. Suppose you have determined that an alloy of 95 wt.% Cu will give you the maximum mechanical properties. To further enhance mechanical properties you decide to minimize the grain size by recrystallization. Your problem is now to outline a research program that would arrive at an optimum mechanical and thermal treatment to minimize the grain size. Explain what variables you would control and how your recrystallization treatment fits in with the precipitation hardening reaction that is also required. 6 MATERIALS SCIENCE ATTEMPT 1 OR 2 1. A. Calculate the linear atomic density in atoms per millimeter in the following directions in FCC aluminum: (a) [100]; (b) [110]; and (c) [111]. B. Calculate the planar atomic density in atoms per square millimeter for the (0001) plane in HCP cadmium. 7 2. Given the following applications, choose the best initial choice of material for the application. Include in your answer specific metals, polymers, ceramics or composites. Justify your selection by using appropriate physical/mechanical properties of the material. A. B. C. D. artificial tibia (leg bone) engine block car or truck hood natural gas fuel tank. 8 MECHANICAL METALLURGY ATTEMPT 1 OR 2 1. The Paris equation for the fatigue crack propagation in a ferritic steel was found to be: da/dN = 3.6 X 10-10 (K)3 The yield strength of this steel is ° = 180 Ksi and the fracture toughness is KIC = 80 ksi (in).1/2 Non destructive testing has shown an initial flaw size of 0.1 inches. This component is cycled between stresses equal to 30 ksi and 5 ksi. Calculate the life time of this component expressed in number of cycles and explain precisely all your assumptions. 9 2. A thin-walled tube 10 inches long has a wall thickness of 0.05 inches and an initial outside radius of 2.5 inches. The plastic stress-strain curve for this material is given by: _ = 85,000 (_ ) 1/2 The tube is subject to an axial load P and a torque T so that the ratio zo/z = 1 at all times. The deformation is continuous until the effective stress equals 30 ksi. Calculate: a) The final dimensions of the tube b) The final axial load and torque.