Electronics Laboratory - E

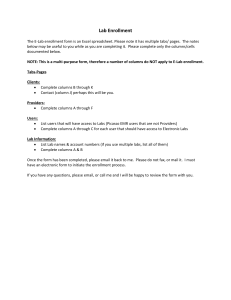

advertisement