fishhone diagram

advertisement

fishbone diagram

nputeventsreduces

training drivers to

3S.

n the eventabove

or you might

causesof

mlts,stress

247

' Another mathematical

analysisdefines theminimar cut set, which

is the

smallestcombinationof causesthat results

in the top "u"nr. Use softwarefor

that analysisalso.

' Fault tree analysisshares

featureswith the why-why diagram but is

more

structured.At eachlever of the fault tree, asking .,why?';leads

ro causesat

the nextlowerlevel.

' Fault tree analysisis

a deductivemethod.You start with a failure

eventand work

your way backwardto specific causes.In

contrast,failure modesand effects

analysisis an inductive method.you start with

specificfailuresand work your

way forward to consequences

of thosefailures.As a result,FMEA is a broader

process'usedfor anaryzingentire systems

or processes.

FTA is a narrowerprocess,

appliedto one failure at a time. It can be used

within the FMEA processto under_

standthe causesof failure modes.

fishhone diagram

r.A;

t'{}

-..L

used.There are

lr a srtuation.

usethe

)utput

rsethe

vertically,

notesfor

fferent

'hileit

is

rctingtrees.

rly in design,

fications.

ay require

til a failure

ed customers,

:r. Use

Lbilities.

t/

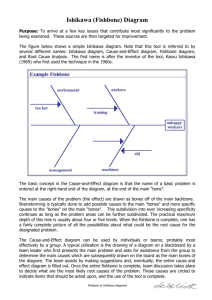

Also called: cause-and-effect

diagram,Ishikawa diagram

variations:causeenumerationdiagram,process

fishbone,time-delayfishbone,CEDAC

(cause-and-effect

diagram with the addition of cards),desired-result

fishbone,reverse

fishbonediagram

Description

Thefishbonediagramidentifiesmany possible

causesfor an effector problem.It can be

usedto structurea brainstotmingsession.It immediately

sortsideasinto usefulcategories.

When to Use

. When identifyingpossible

causesfor a problem

' Especiallywhen the

team'sthinking tendsto fall into ruts

Procedure

Materialsneeded:flipchart or whiteboard,

marking pens.

l' Agree on a problem statement(effect).write

it at the centerright of the flipchart

or whiteboard.Draw a box aroundit and draw

a horizontalarrow running to it.

2. Brainstormthe major categoriesof causes

of the problem.If thereis difficulty

here' use generic headings:methods,machines(equipment),

people(manpower),

248 fishbone diagram

categoriesof causesasbranches

materials,measurement,environment.write the

from the main arrow.

"Why doesthis

problem' Ask

3. Brainstormall the possiblecausesof the

it as a branchfrom the

happen?,,As eachid"a is given, the facilitator writes

placesif they relateto

appropriatecategory.caules can be written in several

severalcategories.

"Why doesthis happen?"about eachcause'Write subcauses

4. Ask again,

..Why?'' and generatedeeperlevels

branchingoff the causes.Continueto ask

of causes.Layers of branchesindicatecausalrelationships'

5.Whenthegrouprunsoutofideas,focusattentiontoplacesonthefishbone

where ideasare few.

Example

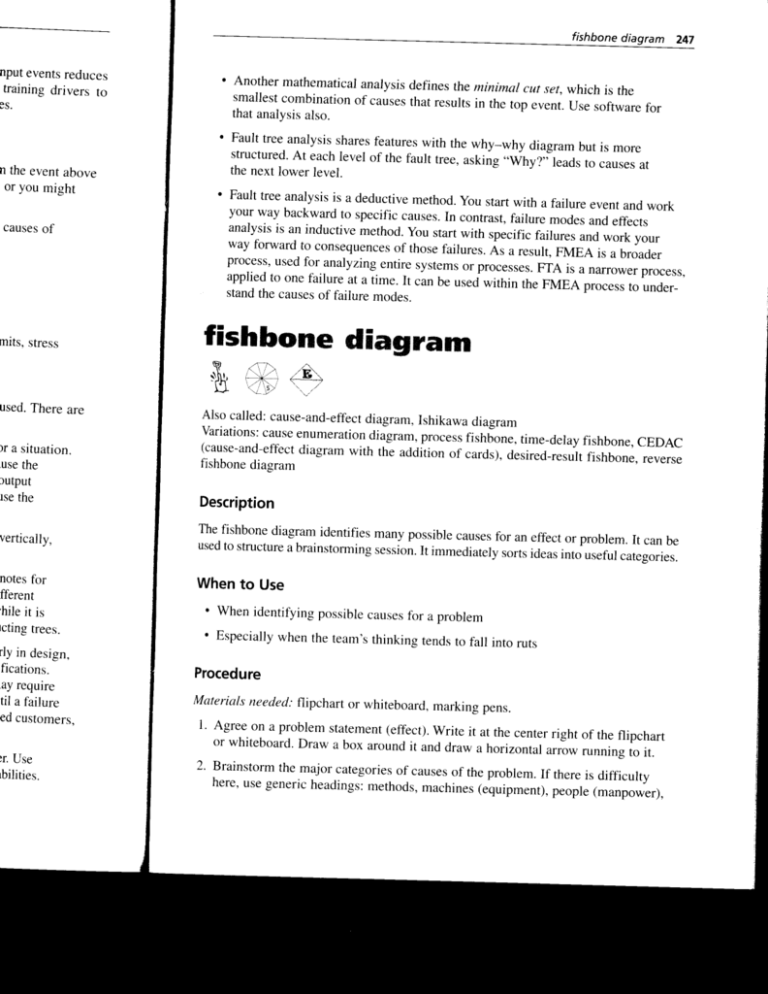

zz-400 manufacturingteamto fiyt0

Figure 5.59 is the fishbone diagramdrawn by the

This example is part of theZZ'

understandthe sourceof periodic iron contamination.

the six genericheadingsto prompt

400 improvement,tory in chapter 4. The team used

the causesof the problem'For

ideas.Layers of branc'hesshow thoroughthinking about

"Machines"' the idea "materials of construction"shows

example, under the heading

numbers'Someideasappeat

four kinds of equipmentanithen severalspecificmachine

"Methods,"

"calibration" showsup under

as a factorin theanain two different places.

"Measurement,"as a causeof lab error' "Iron t00ls"

lytical procedure,and also under

Measurement

Materials

Methods

Lab error

Inexpenenceo

analysl

Maintenance

E'"{'

Heat exchangerleqk

S"s

a - /

Environment

Manpower

F i g u r e5 . 5 9 F i s h b o ndei a g r a me x a m p l e

Machines

fishbone diagram

of causes

as branches

ty doesthis

branchfrom the

:sif theyrelateto

.esubcauses

ratedeeperlevels

rn thefishbone

249

"Methods" problemwhen taking samplesor a "Manpower" problem

canbe considereda

with maintenancepersonnel.

Also seethe St. Luke'sHospitalstoryon page72for anotherexampleof a fishbone

diagramusedwithin the improvementprocess.Seethe Medrad story on page 61 for an

exampleof a nontraditionalway to conduct a fishboneexercise.

cause enumeration diagram

Materialsneeded:sticky notesor cards,marking pens,large work surface(wall, table,

floor),flipchart paper.

l. Agree on the problem statement.

acturingteam to try to

tple is part of the ZZ'ic headings

to prompt

:s of theproblem.For

'construction"

shows

rs. Someideasappear

asa factorin the anaab error."Iron tools"

2. Brainstormall possiblecauses,using any brainstormingtechnique.(See

brainstorming andNGT.) Record on sticky notesor cards.Continueuntil the

group has run out of ideas.

3. Using an affinity diagram,group the causesand determineheadings.

4. Using the headingsas main causes,arrangethe ideason a fishbone drawn on

flipchart paper.

5. Use the fishbone to explore for additionalideas,especiallywhere there are few

ideason the fishbone.

process fishhone

Also called: productionprocessclassificationdiagram

Materials needed:flipchart paper,marking pens.

l. Identify the problem to be studied.Develop a flow diagram of the main steps

of the processin which the problem occurs.There shouldbe fewer than 10.

Draw them as a seriesof boxesrunning horizontally acrossa flipchart page,

with arrows connectingthe boxes.

*Y -

l

b%

n

e

-'X1

Out

'z;

+^

"-

2. Draw a separatefishbone for each step of the process.Takeeachone in turn and

brainstormcausesarising from each step.Also, considerthe handoff from one

stepto anotherand the causesof quality problemsthat occur there.

3. Continue to brainstormsubcauses,as in the first procedure.

Eryerlga!

q

time-delay fislthane

Materials needed:flipchart paper,marking pens,tape,large wall space.

L Begin a fishbone as in steps I and 2 of the main procedure.