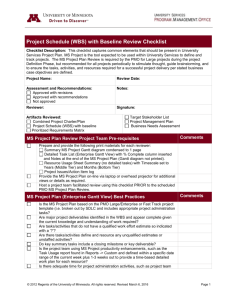

The Work Breakdown Structure (WBS)

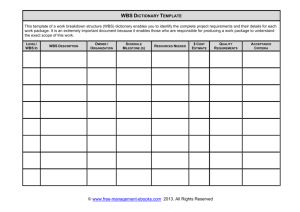

advertisement

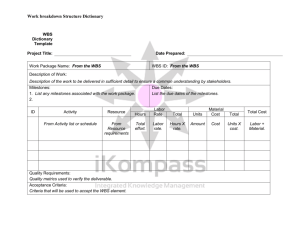

Work Breakdown Structure (WBS) Work Breakdown Structure A Product-Oriented Family Tree that Establishes the Framework for Correlating Program Planning, Scheduling, Cost Estimating, Budgeting, Contracting, Configuration Management, and Performance Reporting Work Breakdown Structure • Developed Early in the Conceptual Phases of the Program but no Later than the Proposal Phase • Kept Current, Evolving with Changes in the Program • Driven by Risk - the Higher the Risk, the Lower the Level • Developed for any program regardless of size and complexity • Links SOW, Schedule, and PMB for program management Special Considerations • Each hardware Element Includes all Effort Associated with; • Hardware Design • Software • Procurement • Manufacturing • Unit Test • Use Specific Terminology, Not Generic Terms • Meaningful Product or Management Oriented Indentures • Not Required to Go to Same Level in all Areas • Recurring and Non-Recurring are Types of Cost Not WBS Levels • Cost Accumulation/Cost Requirements • Establish Cost History • Customer Requirements; Levels, Breakouts, etc. WBS Development Process Gather Data & Review Select Initial WBS Framework Expand WBS Develop RAM Review & Reconcile Obtain Approval Review Documentation Gather and Review Data • RFP • RFQ • CLINS • SOW • CDRLS • Hardware/Software Def. Specifications Drawing Tree BOM • IMP/IMS • Major Interfaces Document Structures and Requirements • Excel Workbook Analyze Relationships • List Structures in Columns and • List Requirements in Columns • List Reference Data in Columns Group Like Elements •Specifications • List Groupings in WBS Column •Drawing Tree •Etc. Review Documentation Statement of Work LXAA Review Documentation 3.1 Program Management NGOS shall organize, coordinate and control all program activities to insure the correct and timely delivery of all materials and services specified in this contract. 3.8 Data Management 3.9 Configuration Management 4.1 Outboard Array Group NGOS shall provide two complete array groups, one per shipset. This hardware shall meet the requirements of the LXAA Performance Specification and CDP. The first array unit of shipset 1 will be delivered for full A/V testing at Lake Seneca and will be returned to NGOS after the test for refurbishment. 4.2 Outboard Cable Assembly NGOS shall design, qualify and deliver the outboard cable assemblies. Qualification testing shall be in accordance with the applicable sections in the PPD xxxxxxxxxxxx, Fiber Optic, Fiber Optic/Electrical Hybrid Hull Penetrator. NGOS will hold a critical design review of the cable assembly prior to cable build. 4.3 Installation & Checkout Spares NGOS shall recommend and provide pricing for installation & checkout spares for installation of the Outboard Array Group. Review Documentation Contract Between Lockheed Martin Naval Electronics & Surveillance Systems Manassas, Va, U.S.A. 20110-4157 1. ACCEPTANCE 1.1 Factory Inspection and Test and Factory inspection, test and acceptance for item 001 and 002 shall take place at the Seller's and/or Seller's subcontractors' facilities in the United States of America in Northrop Grumman (NOCS) accordance with the Seller's Factory Acceptance procedures. Factory acceptance of the Baltimore, Maryland U.S.A. 21203 paragraph 3.2, on the Certificate of Factory Acceptance (Exhibit 2); all other items will line item 001shall be indicated by the Buyer's and Seller’s signatures, as required under be accepted by the Sellers Quality representative. For Line Items 001 and 002, following discussions with the Buyer, the Seller shall For the Delivery of LXAA Shipset 1&2notify the Buyer in writing fifteen (15) days in advance of the scheduled inspection and test to allow the Buyer time to attend. In the event that Buyer informs Seller at least ten (10) days prior to the date of the scheduled inspection and test that Buyer is unable to attend, Buyer and Seller shall mutually agree on an acceptable alternate date for such inspection and test to be conducted within seven (7) days of the date originally set. In the event the Buyer does not attend by the end of the seven (7) day extension, the signing by the Seller of the Certificate of Factory Acceptance by an authorized representative of Seller's Quality Assurance Department shall constitute acceptance. Group Like Elements SOW WBS Specifications LXAA Program Systems Engineering 4 Production Tasks 4.1 Outboard Array Group Cable Assembly 4.2 Outboard Cable Assembly Factory Acceptance Test 4.4 Factory Acceptance Test 4.5 Test Reports 7 Program Management 7.2 Master Program Schedule Outboard Array Build Program Management Program Manager Program Planning and Control 7.4 SDRL Requirements 1. ACCEPTANCE 1.1 Factory Inspection and Test WBS Development Process • RFP • RFQ • CLINS • SOW • CDRLS • Hardware/Software Def. Specifications Drawing Tree BOM • IMP/IMS • Major Interfaces Gather Data & Review Select Initial WBS Framework Expand WBS Develop RAM Review & Reconcile Obtain Approval Work Breakdown Structure • Best Business Practice – Standardized WBS Approach Enhances Life Cycle Traceability – Assist in Parametric Estimating WBS Templates Aircraft System - Platform/Subsystems Electronic/Automated Software System Development - One Level Below the LRU Level Production Missile System - Ordnance Systems Weapon System: Vehicle & Payload - Munitions & Firing/Launching Mechanism Ship Systems - Platform & Subsystems Space Systems - Platform & Subsystems Surface Vehicle Systems - Platform & Subsystems (Added detail available in Military handbook 881) Standard WBS Templates Electronic/Automated Software Systems Development Work Breakdown Structure and Definitions A Electronic/Automated Software System AA Prime Mission Product (PMP) AAA Major Assy 1 - Specify Product/LRU/Config item (CI) etc AAAA AAAB AAAC AAAD AAAE AAAF AAAG (Item 1) - Design/Development of Hardware (Item 1) - Hardware (Item 1) - Applications Software (Item 1) - Subsystem Software (Item 1) -Integration, Assy, Test & Checkout (Item 1) - Product Follow Subassembly 1 - Specify Product/SRU/CI, etc AAAGA AAAGB AAAGC AAAGD AAAGE AAAGF AAAH (Sub Item 1) - Design/Development of Hardware (Sub Item 1) - Hardware (Sub Item 1) - Applications Software (Sub Item 1) - Subsystem Software (Sub Item 1) -Integration, Assy, Test & Checkout (Sub Item 1) - Product Follow Subassembly 2 - Specify Product/SRU/CI, etc AAAHA AAAHB AAAHC AAAHD AAAHE AAAHF (Sub Item 2) - Design/Development of Hardware (Sub Item 2) - Hardware (Sub Item 2) - Applications Software (Sub Item 2) - Subsystem Software (Sub Item 2) -Integration, Assy, Test & Checkout (Sub Item 2) - Product Follow WBS Development Process • RFP • RFQ • CLINS • SOW • CDRLS • Hardware/Software Def. Specifications Drawing Tree BOM • IMP/IMS • Major Interfaces •Templates Gather Data & Review Select Initial WBS Framework Expand WBS Develop RAM Review & Reconcile Obtain Approval Expand WBS Define Line Items Level 1 Level 2 Level 3 ... Using “Grouping of Like Elements” Excel Worksheet Define WBS • Work Downward - Level by Level, Section by Section • Define “Prime Mission Hardware” Based on Hardware Family Tree • Define All Other Breakouts Based on Logical Groupings of Like Activities • Eliminate Non-Applicable Template Elements • Ensure All Contract Effort is Accounted for Key Consideration: • Level of Detail - How Far Down? Level of Detail Required Levels of Detail Factor Least Most Risk: •Technical •Cost •Schedule Low Risk Historical •New Product •Parametric Estimating One of a Kind Product Size of Program: •$ •# of Tasks Small Management Visibility Requirement More Experienced Staff Less Experienced Staff Built Product Before Never Built Product Before High Risk Follow-on Business Large LWWAA Program HF Sail Array LXAA consists of : of: LWWAA consists • Six array units • Eight acoustic modules per array unit • - Fifty-six elements per acoustic module Two AN/WLY-1 ROC Sensors per array unit - One high and one low frequency sensor HF Chin Array AN/WLY-1 LF ROC Sensor AN/WLY-1 HF ROC Sensor Corner #1 Transition (2) One of 8 Fiber Optic Acoustic Modules Center Transition (4) Short Faring Assembly (w/ 4 VIMs) Corner #2 Transition (2) Cable Covers (2) Toe Piece Long Fairing Assembly (w/ 7 VIMs) WBS - Example Occasionally the customer will dictate the WBS Structure to be used on a program: WBS WBS 92G110 or Description 1.1.2.1.3 Program Management However, this WBS Structure doesn’t fit within the accounting system of your company: AA Program Management The solution is simple with most software, you can create a primary WBS field and link it to a alias field for reporting to the customer: 92G110 Links to AA Program Management WBS - Reporting Level WBS A AA AB AC AD AE AF AG B D S T Description LXAA Program Program Management Data Management Business Management Systems Engineering Technical Support Configuration Control Shipyard Installation Support Cable Assembly Outboard Array Build Test & Evaluation ILS Support Alias 92G100 92G110 92G120 92G200 92G211 92G231 92G300 92G340 92G343 92G610 92G700 WBS - Managing Level DA or 92G343 - Port Forward Array Assembly (SS#1) AN/WLY-1 LF ROC Sensor AN/WLY-1 HF ROC Sensor Corner #1 Transition (2) One of 8 Fiber Optic Acoustic Modules Center Transition (4) Short Fairing Assembly (w/ 4 VIMs) Corner #2 Transition (2) Long Fairing Assembly Cable Covers (2) Toe Piece (w/ 7 VIMs) WBS - Managing Level A LXAA 92G100 AA Program Management AAA Program Manager AAAA Production Readiness Review AAB Operations Support (OPM) AAC Technical Publications AB Data Management 92G110 ABA Data Manager 92G120 AC Business Management ACA Business Manager ACB PP&C ACC Financial Reporting ACD Contracts AD Systems Engineering 92G211 92G211 AE Technical Support 92G231 AF Configuration Control AG Shipyard Installation Support 92G300 B BA BB BCX BDX Cable Assembly Cable Assembly SS#1 Cable Assembly SS#2 Raw Cable Connectors 92G340 D Port Forward Array Assembly (SS#1) DA DB DC DD DE E EA-EE F EA-EE G EA-EE H EA-EE J EA-EE S SA SB Array Assembly 92G343 Short Fairing Assembly 92G343 92G343 Long Fairing Assembly Painting/Coating 92G343 92G343 Test & Evaluation Stbd Forward Array Assembly (SS#1) 92G343 Same as DA-DE Port Mid Array Assembly (SS#1) 92G343 Same as DA-DE Stbd Mid Array Assembly (SS#1) 92G343 Same as DA-DE Port Aft Array Assembly (SS#1) 92G343 Same as DA-DE Stbd Aft Array Assembly (SS#1) 92G343 Same as DA-DE ILS Spares Ship Set #1 Ship Set #2 92G700 92G700 Develop WBS Index Define Line Items Level 1 Level 2 Level 3 ... Develop WBS Index • Add WBS Structure to “Grouping of Like Elements” Worksheet • Matrix That Relates all Contract Elements and Requirements Develop WBS Dictionary Define Line Items Level 1 Level 2 Level 3 ... Develop WBS Index • Add WBS Structure to “Grouping of Like Elements” Worksheet • Matrix That Relates all Contract Elements and Requirements Develop WBS Dictionary • Listing that Summarizes Specific Activities Included in Each WBS Line Item WBS Dictionary D Port Forward Array Assembly DE Test & Evaluation DEA Factory Acceptance Test DEB Installation & Checkout Northrop Grumman will conduct Factory Acceptance Tests (FATs) in its facilities on the equipment it provides. The LXAA PMO, at its option and expense, may witness any of the FAT’s. Northrop Grumman shall provide knowledgeable personnel to install, Test, and adjust the LXAA equipment supplied by Northrop Grumman. Northrop Grumman field personnel, consisting of engineers and Expert technicians will receive, unpack, inventory, install, inspect, checkout, and integrate the LXAA Array Assembly. All tools, safety equipment, test equipment, and material handling equipment required for this work will be provided by Northrop Grumman on a temporary import basis. The installation will be performed according to all drawings and standard workmanship practices. WBS Development Process • RFP • RFQ • CLINS • SOW • CDRLS • Hardware/Software Def. Specifications Drawing Tree BOM • IMP/IMS • Major Interfaces •Templates •Define levels •WBS Index •WBS Dictionary Gather Data & Review Select Initial WBS Framework Expand WBS Develop RAM Review & Reconcile Obtain Approval Responsibility Assignment Matrix (RAM) Organization Breakdown Structure • Correlates the Program Management Organization Structure with the WBS Work Breakdown Structure x x x x x xx x x x • Purpose: To Identify/Assign Responsibility for Every Program Element of Work • Points Where WBS and OBS Intersect are Control Accounts Organization Breakdown Structure (OBS) LXAA Program Program Management Program Mgr Data Mgr PP&C Financial Reporting Contracts Assembly System Eng Mfg Engr. Subcontracts Manufacturing Facilities Construction Facilities Eng Arch & Eng Sub Subcontracts Field Engineers Spares Logistics Eng Subcontracts Manufacturing Site Accept Testing System Eng Field Eng Training Instructors Tech Data •Identifies the Way the People Who Will Accomplish the Work Have Been Organized •Developed to the Level of Responsibility/Accountability •Technical/Cost/Schedule •WSA Level The Control Account Definition: The Point at Which the Lowest Level of the WBS and the Lowest Level of the Organization Intersect Level at Which All Elements of Work are Managed & Technical, Cost, Schedule Performance, and Quality are Measured Responsibility Assignment Matrix (RAM) W BS ID PROGRAM R E Q U IR E M E N T S A AA AAA AAAA AC ACA D DA DB DC LX A A P ro g ram M an ag em en t P ro g ram M an ag er P ro d u ctio n R ead in ess R eview B u sin ess M an an g em en t B u sin ess M an ag er P o rt F o rw ard A rray A ssy A rray A ssem b ly S h o rt F airin g A ssem b ly L o n g F airin g A ssem b ly DD DE S SA SB P ain tin g /C o atin g T est & E valu atio n IL S S p ares S h ip S et #1 S h ip S et #2 P ro g ram M g t A ssem b ly J.S m ith T .W o o d s X X X X X F acilities S ite C o n stru ct S p ares T B .P eters C .R o g ers R .H X X X X X X X X X X X WBS Development Process • RFP - RFQ - CLINS - SOW • CDRLS - MP/IMS • Major Interfaces • Hardware/Software Def. Specifications Drawing Tree BOM Gather Data & Review •Templates •Define levels •WBS Index •WBS Dictionary Select Initial WBS Framework Expand WBS Review & Reconcile Obtain Approval •WBS •Organization •Control Account Develop RAM Reviews and Reconcile WBS • Compare WBS, WBS Index, WBS Dictionary and RAM • Ensure that All Elements of Work Have Been Accounted For • Responsibility Each Element of Work has Been Assigned - Control Account • Review with Program Manger and Control Account Managers for Concurrence • Identify Errors, Omissions and Changes • Determine Recognition of Responsibility WBS Development Process • RFP - RFQ - CLINS - SOW • CDRLS - MP/IMS • Major Interfaces • Hardware/Software Def. Specifications Drawing Tree BOM Gather Data & Review •Templates Select Initial WBS Framework •Define levels •WBS Index •WBS Dictionary Expand WBS •WBS •Organization •Control Account •Completeness •Responsibility Develop RAM Review & Reconcile Obtain Approval WBS Approval • Conduct a Final Review Meeting to Approve the WBS After Incorporating all Modifications Identified During Lower Level Reviews • Approval Signatures: – Proposal/Program Manager – Business Manager • Issue WBS, WBS Index, WBS Dictionary and RAM to Program Staff WBS Development Process • RFP - RFQ - CLINS - SOW • CDRLS - MP/IMS • Major Interfaces • Hardware/Software Def. Specifications Drawing Tree BOM Gather Data & Review •Templates Select Initial WBS Framework •Define levels •WBS Index •WBS Dictionary Expand WBS •WBS •Organization •Control Account •Completeness •Responsibility Develop RAM Review & Reconcile •Prog/Proposal Manager •Business Manager Obtain Approval WBS Links All Elements of the Program Pro duc t WBS A LXAA AA Program Management 92G100 AAA Program Manager AAAA Production Readiness Review AAB Operations Support (OPM) AAC Technical Publications D y r o t s i H Long Fairing Assembly 92G343 DC BID 2000 Cost 1850 Period of Performance 2 yr DA DB DC DD DE Port Forward Array Assembly (SS#1) Array Assembly Short Fairing Assembly Long Fairing Assembly Painting/Coating Test & Evaluation P so r e e nn l 92G343 92G343 92G343 92G343 92G343 Pe rfo rm an ce Long Fairing Assembly 92G343 DC BCWS 10 10 10 10 10 10 ACWP 5 10 20 BCWP 5 15 15 CV 0 +5 -5 SV -5 +5 +5 Summary WBS Should: • Organize project information in a logical format • It should be developed in the initial planning stages of the project • The purpose and use will: – Improve communications – Aid in collecting data – Aid in storing historical information in an easy to retrieve and understand format