case study - B2B Marketing Communications

advertisement

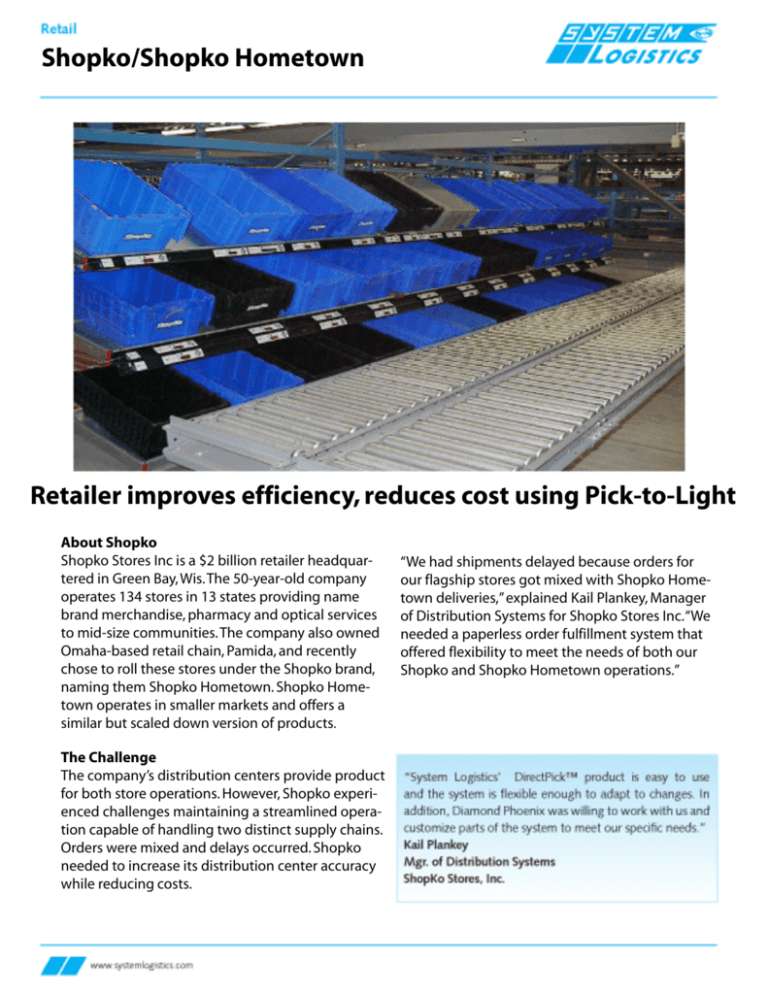

Shopko/Shopko Hometown Retailer improves efficiency, reduces cost using Pick-to-Light About Shopko Shopko Stores Inc is a $2 billion retailer headquartered in Green Bay, Wis. The 50-year-old company operates 134 stores in 13 states providing name brand merchandise, pharmacy and optical services to mid-size communities. The company also owned Omaha-based retail chain, Pamida, and recently chose to roll these stores under the Shopko brand, naming them Shopko Hometown. Shopko Hometown operates in smaller markets and offers a similar but scaled down version of products. The Challenge The company’s distribution centers provide product for both store operations. However, Shopko experienced challenges maintaining a streamlined operation capable of handling two distinct supply chains. Orders were mixed and delays occurred. Shopko needed to increase its distribution center accuracy while reducing costs. “We had shipments delayed because orders for our flagship stores got mixed with Shopko Hometown deliveries,” explained Kail Plankey, Manager of Distribution Systems for Shopko Stores Inc. “We needed a paperless order fulfillment system that offered flexibility to meet the needs of both our Shopko and Shopko Hometown operations.” Shopko/Shopko Hometown The Process Shopko considered several options and providers before making a decision. In-house attempts to resolve the problem failed, so the company looked to order fulfillment providers for solutions. None seemed to meet all the retailer’s needs that included adaptability, self-configurable, and a robust selection of reporting tools. “Several vendors offered a solution to our challenge,” Plankey said. “However, every vendor’s solution failed to meet our requirements until we talked with System Logistics. The Solution System Logistics showed Shopko how to design a paperless order fulfillment system that delivered the flexibility required to pick orders for Shopko and Shopko Hometown stores simultaneously. The DirectPick™ Pick-to-Light system provided an intuitive, self-configurable solution. Vendor containers travel along the conveyor to a put station. Operators remove items from the containers, placing them in designated totes on a rack. The put lights indicate the quantity of items for each tote. When a tote is full, the operator pushes the tote through the rack where it is placed on another conveyor headed to shipping and ultimately to stores. The reporting tools in the system allow Shopko to monitor and measure productivity. This makes it easy for on-the-fly changes and advance planning. The Results Since its installation, the DirectPick™ Pick-to-Light system helped Shopko achieve a 99.69% accuracy in shipments. Furthermore, the reporting tools combined with the excellent metrics allow Shopko to measure the improvements in accuracy and efficiency. Finally, because the system is flexible and self-configurable, Shopko is confident in its ability to handle future growth.