H. Scott Matthews

advertisement

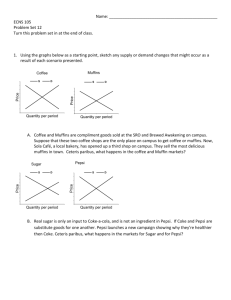

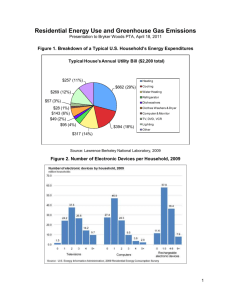

Challenges of Low-Carbon Organizations H. Scott Matthews Carnegie Mellon University 28 Jan 2010 Green Engineering Workshop Sustainable Engineering Many challenges Developing new technologies Assessing and requiring technologies Informing decision makers All critical, I focus on the latter two Metrics: Current Focus on Carbon Sustainability is far more than this Water, quality of life, equity, etc. We will need to tackle all of them, but need to start somewhere. Carbon focus a necessary evil? Relevant Domains CITY COUNTRY CAMPU SES CONSUMER BUSINESS Motivations and Questions to Answer Motivations Carbon Neutrality Commitments: 1000+ cities, 1000+ campuses, 1000+ companies Carbon Labeling, other retail efforts Carbon footprinting and accounting How can we achieve these? Available Tools Lots of “Calculators” Hundreds in active use; mostly consumers Climate Crisis Nature Conservancy carbonfund EPA WWF PBS 5t 66t 8t 22t 9t 15t Calculator “Aggregator” Estimated CO2 Emissions Carnegie Mellon University Campus (2007) THOUSAND TONS PER YEAR 200 100 26 Alternative Footprint View Carnegie Mellon Campus Emissions Corporate Carbon Tools As by WRI/WBCSD and others (standards) Focus on Scope 1 and 2 emissions General Results Average Product - Scope 1 + 2 only 26% of total carbon emissions (refineries ~35%) Two-thirds of products have less than 25% of their emissions in Scopes 1 + 2 i.e., emissions of a majority of products are indirect SOURCE: MATTHEWS, HENDRICKSON, WEBER, “THE IMPORTANCE OF CARBON FOOTPRINT BOUNDARIES”, ENVIRONMENTAL SCIENCE & TECHNOLOGY, VOL 42 NO 16, 2008. Electricity Scope 1+2 an outlier at 90% Sector Scope Averages Scope 3 Dominates, “Everything else” Other Emerging Tools Our Innovation: Product Carbon Calorimeter “TAKING THE GUESSWORK OUT OF PRODUCT CARBON FOOTPRINTING” Total GHGs embodied in product Detail by GHG Detail by Scope 1-3, Detail by Industry , Country of origin Use phase coming soon The “Surprise” This piece of equipment does not exist And can not exist Problem is policymakers (and others, including consultants and some in industry) presume that it already does Thus we need to question “calculators” and also their use Do We Understand The Problem? Number of Purchase Decisions / yr ~100s ~1 ~1 ~1000 Source: Weber and Matthews, Ecological Economics (66), 2008. ut primary “actors” for carbon in consumer product (food, misc) categorie Carbon Labels What was the question? Can we reliably do them? Can we verify them? Should Consumers Use Them? Tools Summary Calculators built to inspire the problem Dirty secrets None are “correct”, all are estimators No ground truth Seem to be missing the big picture We need new tools to make decisions Framework to Support City-Scale Decisions City Climate Action Plans (CAPs) Recall: 1000+ cities have signed Very few have plans (similar to campuses) Because they lack expertise to do more Two pieces: Inventory “a number” Action Plan “a list of activities” AVERAGE = 15 McKinsey GHG Cost Mitigation Curve $10/ton Distributed PV Power Limitations for state & city planning 0.5 1.0 1.3 1.3 1.5 2.0 Regional variability Capital costs Uncertainty Transparency Jurisdiction Split incentives $50/ton CO2 Reductions (billion tons per year) $10/ton 2.5 3.0 Power generation $50/ton Cellulosic biofuels for vehicles Buildings Industrial & waste Forestry & agriculture Transportation $100/ton LEDs in commercial buildings Ref: McKinsey as presented in Miller 2009 26 Existing Programs Nonuniform Totals 15 300 1,100 Ref: DSIRE 2009 27 21 tons eCO2/capita/yr 20 tons eCO2/capita/yr 9 tons eCO2/capita/yr Case Study: Pittsburgh Scenario: Replace with Retirement Objective & Constraint: Max GHG reductions given annual budget constraint Complete All Projects Significant Uncertainty 28 13 20 tons eCO2/capita/yr 16 tons eCO2/capita/yr 6 tons eCO2/capita/yr Case Study: Austin Scenario: Replace with Retirement Objective & Constraint: Max GHG reductions given annual budget constraint 29 14 Conclusions What are the costs & benefits of local building efficiency programs? Typical capital costs <$3/capita/ton/yr up to a 20% GHG reduction uncertainty program design? How 20-yrdoes surplus around impact $1,000/ton/capita Capital costs for GHG reductions $0 to $20/capita/ton/yr Savings of $300 - $400 NPV/ton expected for 10-50% reduction Uncertainty makes capital planning challenging BUT these were all technological fixes! Conservation much easier. 30 Lessons on the Challenge “It” is large and uncertain The expertise is lacking, but centralized Completely new tools are needed Thank You Questions? hsm@cmu.edu