Part 12 - MEMS Packaging - Electrical and Computer Engineering

advertisement

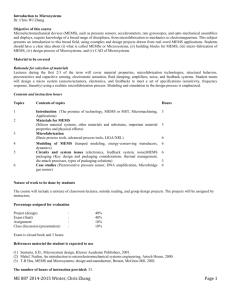

Fall 2008 EE 410/510: Microfabrication and Semiconductor Processes M W 12:45 PM – 2:20 PM EB 239 Engineering Bldg. Instructor: John D. Williams, Ph.D. Assistant Professor of Electrical and Computer Engineering Associate Director of the Nano and Micro Devices Center University of Alabama in Huntsville 406 Optics Building Huntsville, AL 35899 Phone: (256) 824-2898 Fax: (256) 824-2898 email: williams@eng.uah.edu High Volume MEMS: Devices, Stability, Packaging • • Place MEMS die onto dip chip package, wire bond, and vacuum seal Issues: – – – – • Dip chip packages are plastic Ceramic dip chip packages are difficult to seal Long term metal to metal packaging fails Difficult to achieve high vacuum for device performance and maintain it over years Solution: Encapsulate the MEMS device on chip then package the MEMS/IC chip using standard technologies Figures taken from: DMD commercial Success • • • Robust Manufacturing with high yield and single release process allows for fabrication of Texas Instruments DLPs Anodic Bond Package to transparent Pyrex 7740 Glass provides sufficient vacuum for DLP response Package is sealed over large area with wide bond seam to prevent long term failure Figures taken from: Motorola / Freescale Pressure Sensor • • • • • • • Single Crystal sensor mounted in injection molded thermoplastic case Machined cap Silicone oil (most tested oil in the history of mankind) No direct IC package integration. Simple wire bonds from the package are sufficient Process utilizes 25 years of experience in pressure sensors at Motorola Very little work in novel MEMS process development No vacuum sealing of MEMS component required Figures taken from: AMD Accelerometers • • • First integrated surface microdevice on the market (1993) Perhaps the largest market device in MEMS today Package does not include MEMS encapsulation. Entire die is vacuumed hermetically sealed in IC package Figures taken from: Motorola’s MMA Air Bag Sensor • • • • 3 layer poly process proven over multiple years of preproduction Complete IC integration Packaging still performed at the die level No independent MEMS encapsulation Figures taken from: SOI Based Optical MEMS by Analog Devices • • • • CNP and silicon bonding of multiple SOI wafers allows for complete IC integration of tilt mirror optics SOI integration allows for low voltage electronics and high voltage MEMS mirrors to be integrated directly on the same die Independence of MEMS is provided by multilayer device fabrication and bonding Encapsulation is still performed at the die level Figures taken from: Package Protection from Dicing • • • Dicing Problems with MEMS MEMS components can be easily damaged or destroyed by water and particles present during the dicing process This is overcome by a number of methods – – – Release is often performed after dicing Motorola and Bosch use glass frit is used to seal MEMS components prior to dicing then etched away after. TI DLPs required a different solution • • • • First mirrors are released Protective organic film placed on mirrors allows for normal cleaning processes Dicing occurs Singulated chips are mounted on ceramic packages prior to dry etching organic layers Figures taken from: Packaging MEMS that need Separate Encapsulation • • • • • Conventional MEMS devices are fabricated, packaged, and connected to IC control circuits for commercial use The more compatible the fabrication scheme is with IC processing, the easier the device is to integrate However, some devices such as the one pictured, are not directly compatible with IC processing at all In both cases, MEMS are manufactured, packaged, integrated either on chip or off chip with an IC, then packaged using dip chip technology and released to the market Problem: MEMS encapsulation is not simple or easy – – – • Issues with bond seams Issues with material compatibility Issues with vacuum Today: DARPA BAA call currently out to generate a low power MEMS based high vacuum device for integration directly into MEMS packages. Cost will probably be $2- 15M per team over 3 years depending on nature of team and requirements for industrial success • The Big Question: How does one get the MEMS component sealed from the remainder of the IC and device package while still providing sufficient interaction with the sensing environment????? Figures taken from: Various Bonding Mechanisms Figures taken from: Permeability of Materials for Packaging to Water • • • Although some polymers such as BCB are better than others, packaging with polymers does not provide a long term solution for commercial devices Glasses provide relatively long term seals if the width of the bond seam is sufficient. – bond seams are 0.25 -1mm wide Metals provide best long term hermiticity – Al-to nitride – Au eutectic: • 0.08 mm bond seam for 320oC • >0.25 mm bond seam for Temp below 250 um – AuIn eutectic: >0.3 mm bond seam BCB Polymer bonding • • Advantages – Low bond temp – No metals – Elastic (less worry about CTE mismatches) Disadvantages – Long term permeability of water – High vapor pressure – Poor mechanical properties Ideal upper limit: 1*10-9 mbar l/s Sealant used was Si3N4 Gold Compression Bonding • • • Au/Au eutectic: 0.08 mm bond seam for 320oC >0.25 mm bond seam for Temp at 220oC S.M. Spearing, C.H.Tau, M.A.Schmidt, “Gold Thermocompression Bonding,” AMMNS 2008 K. Entesari, G. Rebeiz, “Allow-loss microstrip Surface Mount K-band Package,” 36 European Microwave Conference, 2006. Anodic Bonding • • • • • • Bonds alkali glass such as Pyrex 7740 to Silicon Best performance when CTE of glass and substrate match Stresses induced by thermal strains can fracture device Reasonably hermetic Electrically insulated Common process conditions – – Figures taken from: 200-300 oC 200-1000 V (400-600 V is usually sufficient for 200 um seals) Silicon Fusion Bonding • • • • • • Bonding performed in EV520 at 600oC First bonded for 5 hrs – Razor used to test bond strength at side and base of wafer Second bond for 12 hrs – IR transmission measurements made – About 5 or 6 measurable voids in the wafer stack – Only 1 over the devices near the center of the wafer Next Steps: – Anneal in furnace for at least 2 hrs at 1100oC – Perform CSAM measurements – Dice stack Issues: voids and stress cracks in complex shapes No long term testing of hermeticity published to date Void/ Newton fringe Cracks in the pattern JDW/SNL DARPA-NAV PSG Packaging • • • Process developed in early 90’s Unable to meet long term cycling demands Very difficult to create high vacuum seal in PSG packages Figures taken from: Aluminum Packaging • • Figures taken from: High temperature processing of Aluminum films on SiO2 or Si3N4 yields hermetic seam between structures Bond strength is estimated to be 270 MPA which is stronger than the glass fracture strength Al-to-Si3N4 RTP bonding Figures taken from: Combining PSG and Glass-Al-Poly Figures taken from: Resonator Performance in MEMS Packaging Figures taken from: Previous Process uses Localized Polysilicon Heater to Create Bond Figures taken from: Failure of Rapid Thermal Processes Packages • • Predictions of the mean and standard deviation time to failure (MTTF) For worst case scenario 4 in 31 samples failed by the end of the test – 90% chance based on worst case that the package will fail in 0.57 years Figures taken from: Accelerated Lifetime Testing Figures taken from: Example of Failed Package • • • In all bond processes, localized stresses lead to cracks and defects The size of these defect regions varies based on the process capability of the bond scheme and the process development team Here one can see how stresses might originate and the type of failure that occurs over time Figures taken from: