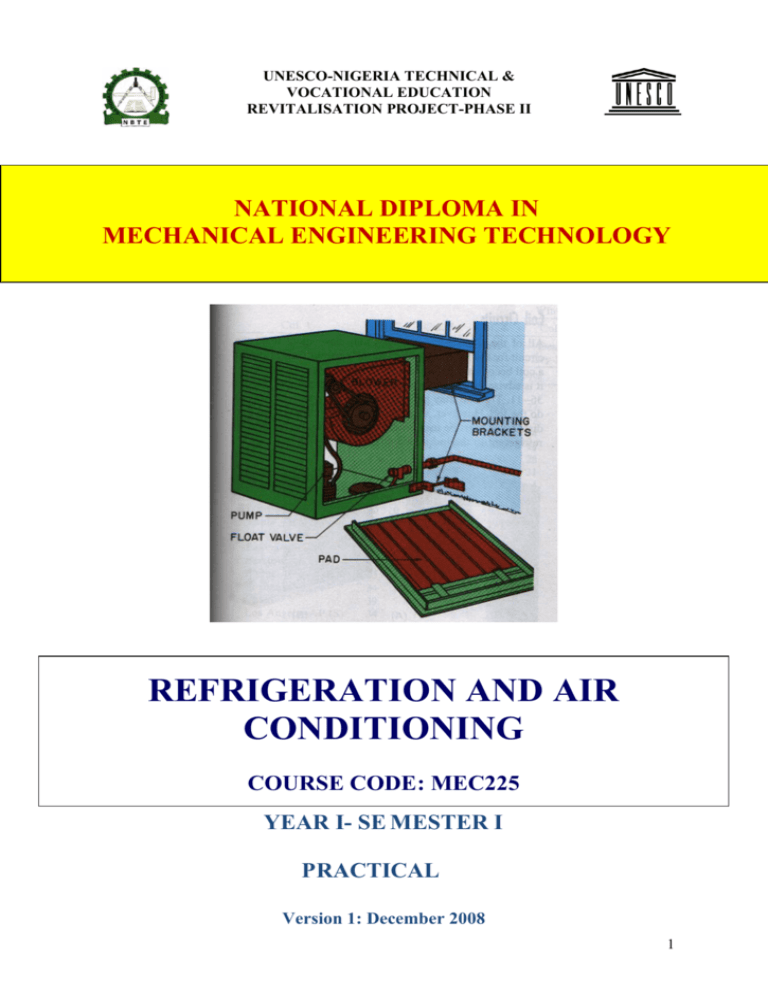

REFRIGERATION AND AIR CONDITIONING

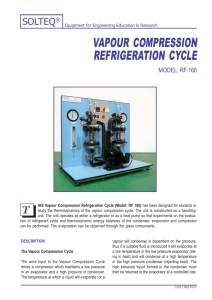

advertisement

UNESCO-NIGERIA TECHNICAL &

VOCATIONAL EDUCATION

REVITALISATION PROJECT-PHASE II

NATIONAL DIPLOMA IN

MECHANICAL ENGINEERING TECHNOLOGY

REFRIGERATION AND AIR

CONDITIONING

COURSE CODE: MEC225

YEAR I- SE MESTER I

PRACTICAL

Version 1: December 2008

1

Table of Contents

Week 1:

To assess the mechanism of cold state production

Week 2:

To determine pressure-temperature relationship using refrigerator

Week 3:

To identify and sketch various components of vapour compression refrigeration

system.

Week 4:

Measurement of properties of air

Week 5:

To determine the coefficient of performance of the Air-conditioning test unit

Week 6:

Measurement of heat transfer rate and estimation of coefficient of performance of a

vapour compression refrigeration cycle.

Week 7:

Measurement of heat transfer rate and estimation of coefficient of performance of a

vapour compression refrigeration cycle

Week 8:

To determine the coefficient of performance of the Air-conditioning test unit

Week 9:

To determine the coefficient of performance of the Air-conditioning test unit

Week 10:

TROUBLE SHOOTING: Self-contained Mechanical Refrigerators

Week 11:

TROBLE SHOOTING: Air handling Units - General

Week 12:

TROBLE SHOOTING: Thermostatic Expansion Valves

Week 13:

TROBLE SHOOTING: Chilled-Water Air handling Units

Week 14:

TROBLE SHOOTING: Air handling Units - Electric Heating Coils

Week 15:

TROBLE SHOOTING: Condensing Units (General)

Week one

Title: Cold State concepts.

Aim: To assess the mechanism of cold state production.

Apparatus:

Conical flask, methylated spirit, trough, thermometer.

Method:

Pour a small quantity of methylated spirit into your palm and allow to vapourise.

Note your feeling on your palm.

Now pour a given quantity of the methylated spirit into a conical flask or beaker.

Pour water in a trough and measure the temperature or

Feel the coldness of the water

Place the conical flask with the content into the water in the rough until all the

spirit vapourises.

Feel the measure the new temperature of water in the trough.

Observations: Note your observation.

Discussion:

Discuss this test and the phenomenon of vapourisation associated with the cold

state achievement

Title:

Concept of cold making

Aim:

To show the direction of heat flow

Apparatus:

Beaker, ice blocks, thermometer stirrer.

Method:

Pour water into a beaker half full.

Measure the temperature of the water and record.

Add some cubes of ice blocks into the water.

Stir the mixture gradually or shake the mixture for a period of three minutes.

Measure the temperature of the mixture.

Record the new temperature

Observation: Note your observations.

Discussion:

Discuss this phenomenon

Title:

Concept of cold making

Aim:

To measure the quantity of heat transfer between two bodies at different

temperatures.

Apparatus:

Conical flask or beaker, ice blocks, water, thermometer.

Method:

Weigh the flask or beaker.

Add a quantity of water, weigh the beaker and water and record.

Measure the initial temperature of water and record.

Add a known mass of ice blocks and stir together until all the ice blocks melt.

Take the thermometer reading of the final temperature of the mixture and record.

Observations/

Result:

Record all the measurements of mass and temperature.

Calculation:

Calculate the quantity of heat transfer from water to ice blocks.

Discussion:

Discuss this test and state the quantity of heat transfer.

Title:

Concept of cold making

Aim:

To show the effect of pressure on temperature.

Apparatus:

(i) Ice block measuring 150 x 75 x 75mm

(ii) A length of string of 500mm

(iii) Weighing hangers 2no.

(iv) A set of weights

(v) Stool

Method:

Place the ice bock on the stool.

Attach the string to the weighing hanger.

Place the string over the ice block.

Add some equal weighs in the weighing hangers.

Allow the assembly to stay for 10 minutes.

Repeat this with different weights.

Observation: Note your observation on the interration between string and ice block.

Discuss:

Discuss this test.

WEEK 2

TITLE:

To determine pressure-temperature relationship using refrigerator II

APPARATUS:

Refrigerator demonstration unit, thermometers, water (cool and

warm)

THEORY:

RII is a refrigerator with chemical name, tichloroflouromethane, and formula, cd3F.

The boiling point is 23.80C (74.90F). At – 150C (50F) suction and 300C (860F)

condensing temperatures, the following parameters are obtained:

Condensing pressure

3.5psig

hy per ITR

0.94

cmf per ITR

36.54

COP

5.03

The colour code for RII is orange and the UL hazard class is 5a. The

refrigerant has a faint, non-flamable and a low pressure refrigerant used mainly in

large low speed centrifuges. It is an excellent solvent much used to wash out

systems contaminated by motor burnants. It is supplied in low pressure drums or

cylinders pressurized with nitrogen as a propellant.

The full physical properties of refrigerants can only be detailed in extensive

and complicated tables and charts which are not easy to understand. Exhaustive

details are not however important to the installation or service engineer or

technician whose needs are concentrated on converting gauge pressures into

temperature or into gauge pressures of each of the refrigerants with which he

works.

Simple temperature to pressure relationships are detailed in the attached

table. The table being the temperature/pressure relationships for various refrigerant

and is straight forward in its practical application. If the installation technician is

balancing an R12 system to run at a saturated temperature of -290C (-200F), he

aims at a gauge reading of 0.6psig. if his discharge gauge reading is 136.4psig, the

table will tell him that the condensing temperature is 43.30C (1100F).

PROCEDURE

1. Charge the refrigerant into the system and allow to reach the desired

quantity.

2. Condition the evaporator and condenser to work at the same temperature by

allowing warm water into the evaporator and cool water into the condenser.

3. When an equilibrium temperature is reached, vary the water flow rate and

record the observed corresponding temperature and pressure.

4. Tabulate the results obtained from the experiment over a practical range and

plot the graph of pressure-temperature relationship.

PRECAUTION

State the necessary precautions taken in the course of carrying out the experiment.

RESULTS/OBSERVATION/GRAPHS:

Tabulate the results obtained and state any unique observation made during the

experiment. Present your results in graphical form and briefly interpret or analyze

it.

RECOMMENDATION AND CONCLUSION

State the reference of this test and highlight specific industrial application of this

test. How can this be used to explain the characteristics and effects of using one

refrigerator in place of another for a domestic refrigerator or window air

conditioner.

Week 3

Title:

Refrigeration components

Aim:

To identify and sketch various components of vapour compression refrigeration

system.

Method:

Pick from the numerous components, provided, sketch, label and briefly describe

each of them.

Discussion:

Discuss the function of each of the components/parts sketched.

WEEK 4

TITLE:

Measurement of properties of air

OBJECT: To determine the relative humidity, humidity ratio, vapor density,

degree of saturation, enthalpy, and dew-point temperature of air by the

use of a sling psychrometer and a psychrometric chart.

APPARATUS:

Sling psychrometer or stationary-bulb psychrometer, mercurial

barometer, psychrometric chart.

Drawing

THEORY:

Liquids, vapours, and gases occur in a great variety of mixtures in fuels, products

of combustion, refrigeration systems, steam boilers, and condensers and in

atmospheric air. Mixtures of air and steam are by far the most common of the gasvapour mixtures. Steam boilers deliver steam containing small amounts of air, and

when this steam is condensed, the problem of air removal arises. Steam turbines,

condensers, and evaporators that operate below atmospheric pressure will admit air

through any leakage areas, and this air must be removed. Since most fuels contain

5 to 25 per cent of hydrogen, products of combustion in furnaces and engines are

gas-steam mixtures. Water cooling by evaporation in air requires the computation

of air-steam mixtures in spray ponds, cooling towers, evaporative condensers for

refrigeration, etc. Humidification and dehumidification of air I all phases of air

conditioning require a variety of computation procedures of air-steam mixtures.

Since humidity affects the behavior of so many commercial materials such as

wood, paper, textiles, paint, tobacco, pastes, and doughs, the control of

atmospheric moisture is a major problem in industrial as well as home air

conditioning. Because air and low-pressure steam behave approximately as ideal

gases, the perfect-gas laws form the basis for most calculations. The ratio of the

constituents of the air-steam mixture may be expressed in either weight or volume.

METHOD:

The accuracy of the wet and dry-bulb thermometers should be noted before the

wick is moistened by reading both thermometers in an air stream when dry. No

difference in reading should be visible in a good instrument. Moisten the wet-bulb

wicking and whirl at about 150 rpm; then read wet bulb first. Whirl, read, whirl,

read until the lowest possible wet-bulb reading is obtained. Use clean water;

distilled water is preferred. Do not touch the wet bulb, as the slightest oily deposit

on the wicking will cause errors. Read mercurial barometer.

CONCLUSION

1. How did you get the relative humidity of the air? The humidity ratio, the

vapor density, the degree of saturation, the enthalpy, and the dew-point

temperatures?

2. What temperature is a measure of sensible heat, total heat and moisture

content?

i.

The psychrometry is the branch of engineering science that deal with the

study of Moisture air. Moisture air consists of dry air mixed with water

vapour or humidity. It also includes the study of behaviour of dry air and

water vapour mixture under various conditions.

ii.

The earth’s atmosphere is a mixture of gases including nitrogen (N 2),

oxygen (O2), argon (Ar), and carbon dioxide (CO2); yet for the purpose of

psychrometry, it is considered to be a mixture of dry air and water vapour

only.

iii.

The dew point temperature is the temperature of air recorded by a

thermometer, when the moisture 9water vapour) present in it begins to

condenser. In other words, the dew point temperature is the saturation

temperature (tsat) corresponding to the partial pressure of water vapour (P v),

it is usually denoted by tdp.

Since PV is very small, therefore the saturation temperature by water vapour at PV

is also low (less than atmospheric or dry bulb temperature).

This is water vapour in air exists in the superheated state and the moisture air

containing moisture in such a form (i.e. in the superheated state) is said to be

unsaturated air.

This condition is shown by point A on T-S chart as shown below. When the partial

pressure of water vapour (PV) is equal to the saturation pressure (PS); the water

vapour is in dry condition and the air will be saturated air.

If a sample unsaturated air containing superheated water vapour is cooled at

constant pressure, the partial pressure (PV) of each constituent remains constant

until the water vapour reaches the saturation state as in point B. at this point B the

first drop of dew will be forward and hence the temperature at point B is called

dew point temperature. Further cooling will cause condensation of water vapour.

From the above illustration, the dew point temperature is the temperature at which

the water vapour begins to condenser.

Dry bulb temperature is the temperature of air recorded by a thermometer

when it is not affected by the moisture present in the air (td or tdb)

Wet bulb temperature is the temperature of air recorded by thermometer

when its bulb is surrounded by a wet cloth exposed to air.

Psychrometer: There are many types of psychrometer but the sling

psychrometer is a common one and is widely used. It consists of a dry bulb

thermometer and a wet bulb thermometer mounted side by side in a

protective casing attached to a handle by a swivel connection so that the case

can be easily rotated. The dry bulb thermometer is directly exposed to air

and measures the actual temperature is covered by a wick thoroughly wetted

by distilled water. The temperature measured by this wick covered bulb of a

thermometer is the temperature of liquid water in the wick and is called wet

bulb temperature.

The sling psychrometer is rotated in the air for approximate one minute after

which the readings are taken from both thermometers. This process is

repeated several times to ensure that the lowest possible wet bulb

temperature is recorded.

WEEK 5

OBJECTIVE:

To determine the coefficient of performance of the Air-conditioning test unit when

acting as:i.

A cooler

ii.

A heat pump

EQUIPMENT

Plint and partners versatemp air-conditioning TE/94/1902, flowmeter, cromption

wattmeter, thermometers.

Student to draw a schematic diagram of the arrangement.

PROCEDURE

Students to write this up as per instructed

THEORY

Conventionally, the air-conditioners is described as a cooler when it is extracting

heat from the surrounding air and rejecting it to the cooling water; and it is

described as a heat pump when it is extracting heat from the water and transferring

it to air.

(i)

The coefficient of performance of the air-conditioning when acting as a

cooler is given by

CPR =

q1

W

Where q1 = heat extracted from air

= mass flow rate of air x Enthalpy drop of air in passing through airconditioner.

Mass flow rate of air can be calculated from the pitot tube mounted in the

discharge duct;

But

Pa

=

RT

P

Where

R

=

287

Pa

=

atmospheric pressure in N/m2.

The velocity of the air U, corresponding to the velocity head H1 cm H2O as

measured in the pitot tube is given by

U2

=

98.1 H1

2

From these, it can be found that the mass flow rate of the air

m1

=

0.00332

H1 Pa

kg/sec.

T2

Where T2 = temperature of the air leaving air – conditioner (0K)

q1 =

m1 CP (T1 – T2)

Where T1 = temperature of air entering air-conditioner

CP = specific heat of air at constant pressure

= 1.005 kj/kg 0K.

W = Power input by fan + compressor + heat gained by water in cooling

refrigerant.

Heat gained by cooling water

=

m2 CP (T5 – T4)

Where CP = 4.19 kj/kg 0K.

From the rotameter the volume of circulating water can be observed and hence the

mass; take the density of water as:(ii)

The coefficient of performance of the air-conditioner when acting as a

heater.

CPH =

q2

w

where q2 = energy gained by air in passing through air-conditioner.

W = power input to fan + compressor + heater

EXPERIMENTAL DATA

TEMPERATURE OF INCOMING AIR.

TEMPERATURE OF OUTGOING AIR

PITOT TUBE DEFLECTION

POWER INPUT TO FAN

POWER INPUT TO COMPRESSOR

POWER INPUT TO HEATER

TEMPERATURE OF WATER AT INLET

TEMPERATURE OF WATER AT OUTLET

RATE OF FLOW OF WATER

BAROMETRIC PRESSURE

CONCLUSION

i.

From standard calculations, the maximum coefficient of performance of

the air-conditioner as a cooler was found to be 6.2.

Compare and

contrast this with your results.

ii.

The maximum coefficient of performance of this air-conditioner as a

heater was also found to be 4.78. Compare and contrast this with your

results.

WEEK 6

TITLE: Measurement of heat transfer rate and estimation of coefficient of

performance of a vapour compression refrigeration cycle.

APPARATUS:

Hilton’s refrigeration demonstration unit.

DRAWING:

See attached schematic diagram of the refrigeration

demonstration unit.

THEORY: The compressor used in this demonstration unit is a diaphragm

compressor of the oil free type which has proved suitable for

this application for the following reasons.

a)

It is unlikely to be damaged by mal-operation of the

equipment (e.g. liquid carry over from the evaporator).

b)

The volumetric efficiency falls fairly rapidly as the

pressure ratio is increased which clearly demonstrates the

reduction

of

refrigerator

performance

under

these

conditions.

c)

The system does not have to be contaminated with oil for

lubrication purpose.

The evaporator is constructed from a thick walled glass cylinder

machined brass end plates. The refrigerant R11 can be see to boil as heat

is transferred from a coil of copper tube through which water flows. A

combination pressure/vacuum gauge indicates the pressure.

The condenser is a similar glass cylinder in which the higher pressure

vapor can be seen to condense as heat is transferred to a similar coil of

copper tuning through which water flows. Thermometers and a

combination pressure/vacuum gauge are provided as in the evaporator.

A float operated needle is situated in the bottom of the condenser. The

valve controls the refrigerant liquid flow rate to match the rate of

condensation at all operating conditions.

PLANT DATA

Refriger/ant – R11 CC13F

quantity – 400-500ml

Compressor: Diaphragm type gas compressor. ¼hpmotor.

Rotational speed – 1425rpm. Volumetric flow at intake

conditions for a pressure ratio of 2:1 = 1.238liter/s

CONDENSER:

Glass cylinder 66.6mm bore. 200mm long.; 4.2mm thick. Copper

tubing 6.35mm diameter.

Heat transfer area (mean) Ac = 0.032 Heat transfer to or from surroundings

= 0.8 (tc-ta) Watts.

EVAPORATOR: Similar dimensions to condenser.

Lett tc – Refrigerant saturation temperature in condenser

= 250C

Pc – Refrigerant saturation pressure in condenser

= 1bar

tc – Refrigerant saturation Temperature in evaporator

= 50 C

pe – Refrigerant saturation pressure in evaporator

= 0.20bar

mc – Water flow rate through condenser

= 20kg/hr

tw – Water temperature at inlet to condenser

tx – Water temperature at outlet from condenser

me – Water flow rate through evaporator

tu – Water temperature at inlet t evaporator

tu – Water temperature at outlet from evaporator

ta – Ambient air temperature

Ac – Heat transfer area condenser

Ae – Heat transfer area evaporator

Be experiment it has been found that the heat exchange rate between the

evaporator or condenser and the atmosphere has been established as 0.8watts

per degree K difference between the saturation temperature and ambient

temperature.

There are three significant energy transfer rates in the refrigeration cycle –

1. The positive heat transfer rate to the refrigerant as it is evaporated

Qe.

2. The negative heat transfer rate as the refrigerant is cooled and

liquefied in the condenser Qc.

3. The negative work transfer rate W to the refrigerant as it passes

through the compressor.

According to the First Law of Thermodynamics, in a cycle, the net heat

transfer is equal to the work transfer, thus

W = Qe – Qc

Qe = Heat transfer rate from (Water + Atmosphere)

Qc = me Cp (tu – tv) + 0.8 (ta – te)

Qc = Heat transfer rate to (Water + Atmosphere)

Qc = mc Cp (tx – tw) + 0.8 (tc – ta)

Coefficient of performance (based on work transfer to refrigerant

COP = Qe/W

Measurement of heat transfer coefficient during evaporation and

condensation:The overall heat transfer coefficient (U) is the heat transfer rate per unit area

of heating surface, when a temperature difference of one degree exists

between the hot and cold fluids. In the case of a heat exchanger, the

temperature difference is the log mean temperature difference which is the

case of the condenser is

LMTDc =

and in the case of the evaporator is

LMTDc =

The heat transfer rate to the water at the condenser

Uc =

Similarly at the evaporator

Ue =

METHOD:

1. Ensure that the refrigerator contains sufficient refrigerator liquid to cover

Evaporator cooling coil under working conditions.

2. Open up water control valves on both evaporator and condenser to high

rate of flow at between (10 - 20) 0C.

3. Switch on compressor and leave for about 10 minutes.

4. Adjust the water flow rates and if necessary the cold water temperatures

to obtain the desired evaporator and condenser pressures.

5. The evaporator and condenser pressures and temperatures are noted and

the rates of boiling and condensation are observed visually.

6. The evaporate water flow rate is considerable reduced and the unit again

allowed to stabilise. The temperatures and pressures are again noted as

well as the rate of boiling and condensation. The condenser pressure can

be controlled b adjustment of the water flow rate.

7. Computer for the COP and heat transfer coefficients during evaporation

and condensation using two sets of readings of pressures and

temperatures (two different water flow rates).

8. Keep the evaporator saturation temperature constant b adjustment of the

evaporator water flow rate and inlet temperature and run a series of tests

at 4, different condenser pressures (controlled by variation of condenser

water flow rate). The related.

9. With the tabulated values found in step 8, construct a performance curve

for the refrigeration Unit using Refrigerating Effect (Watts) vs. condenser

Saturation Temperature (0C) for a constant Evaporator Saturation

Temperature.

CONCLUSIONS:

1. Are the heat transfer coefficients at the condenser and evaporator

constant at different pressures and temperatures?

2. What is the relation between the refrigerating effect and the pressure

ration (condenser pressure/ratio? pressure)? To get the largest

refrigerating effects from a given unit, what should be the pressure ratio?

3. What do you think are the reasons why R11 refrigerant is used in this

demonstration unit?

WEEK 8

TITLE: Measurement of heat transfer rate and estimation of coefficient of

performance of a vapour compression refrigeration cycle.

APPARATUS:

Hilton’s refrigeration demonstration unit.

DRAWING:

THEORY: The compressor used in this demonstration unit is a diaphragm

compressor of the oil free type which has proved suitable for

this application for the following reasons.

a)

It is unlikely to be damaged by mal-operation of the

equipment (e.g. liquid carry over from the evaporator).

b)

The volumetric efficiency falls fairly rapidly as the

pressure ratio is increased which clearly demonstrates the

reduction

of

refrigerator

performance

under

these

conditions.

c)

The system does not have to be contaminated with oil for

lubrication purpose.

The evaporator is constructed from a thick walled glass cylinder

machined brass end plates. The refrigerant R11 can be see to boil as heat

is transferred from a coil of copper tube through which water flows. A

combination pressure/vacuum gauge indicates the pressure.

The condenser is a similar glass cylinder in which the higher pressure

vapor can be seen to condense as heat is transferred to a similar coil of

copper tuning through which water flows. Thermometers and a

combination pressure/vacuum gauge are provided as in the evaporator.

A float operated needle is situated in the bottom of the condenser. The

valve controls the refrigerant liquid flow rate to match the rate of

condensation at all operating conditions.

PLANT DATA

Refriger/ant – R11 CC13F

quantity – 400-500ml

Compressor: Diaphragm type gas compressor. ¼hpmotor.

Rotational speed – 1425rpm. Volumetric flow at intake

conditions for a pressure ratio of 2:1 = 1.238liter/s

CONDENSER:

Glass cylinder 66.6mm bore. 200mm long.; 4.2mm thick. Copper

tubing 6.35mm diameter.

Heat transfer area (mean) Ac = 0.032 Heat transfer to or from surroundings

= 0.8 (tc-ta) Watts.

EVAPORATOR: Similar dimensions to condenser.

Lett tc – Refrigerant saturation temperature in condenser

= 250C

Pc – Refrigerant saturation pressure in condenser

= 1bar

tc – Refrigerant saturation Temperature in evaporator

= 50 C

pe – Refrigerant saturation pressure in evaporator

= 0.20bar

mc – Water flow rate through condenser

= 20kg/hr

tw – Water temperature at inlet to condenser

tx – Water temperature at outlet from condenser

me – Water flow rate through evaporator

tu – Water temperature at inlet t evaporator

tu – Water temperature at outlet from evaporator

ta – Ambient air temperature

Ac – Heat transfer area condenser

Ae – Heat transfer area evaporator

Be experiment it has been found that the heat exchange rate between the

evaporator or condenser and the atmosphere has been established as 0.8watts

per degree K difference between the saturation temperature and ambient

temperature.

There are three significant energy transfer rates in the refrigeration cycle –

1. The positive heat transfer rate to the refrigerant as it is evaporated

Qe.

2. The negative heat transfer rate as the refrigerant is cooled and

liquefied in the condenser Qc.

3. The negative work transfer rate W to the refrigerant as it passes

through the compressor.

According to the First Law of Thermodynamics, in a cycle, the net heat

transfer is equal to the work transfer, thus

W = Qe – Qc

Qe = Heat transfer rate from (Water + Atmosphere)

Qc = me Cp (tu – tv) + 0.8 (ta – te)

Qc = Heat transfer rate to (Water + Atmosphere)

Qc = mc Cp (tx – tw) + 0.8 (tc – ta)

Coefficient of performance (based on work transfer to refrigerant

COP = Qe/W

Measurement of heat transfer coefficient during evaporation and

condensation:The overall heat transfer coefficient (U) is the heat transfer rate per unit area

of heating surface, when a temperature difference of one degree exists

between the hot and cold fluids. In the case of a heat exchanger, the

temperature difference is the log mean temperature difference which is the

case of the condenser is

LMTDc =

and in the case of the evaporator is

LMTDc =

The heat transfer rate to the water at the condenser

Uc =

Similarly at the evaporator

Ue =

METHOD:

1. Ensure that the refrigerator contains sufficient refrigerator liquid to cover

Evaporator cooling coil under working conditions.

2. Open up water control valves on both evaporator and condenser to high

rate of flow at between (10 - 20) 0C.

3. Switch on compressor and leave for about 10 minutes.

4. Adjust the water flow rates and if necessary the cold water temperatures

to obtain the desired evaporator and condenser pressures.

5. The evaporator and condenser pressures and temperatures are noted and

the rates of boiling and condensation are observed visually.

6. The evaporate water flow rate is considerable reduced and the unit again

allowed to stabilise. The temperatures and pressures are again noted as

well as the rate of boiling and condensation. The condenser pressure can

be controlled b adjustment of the water flow rate.

7. Computer for the COP and heat transfer coefficients during evaporation

and condensation using two sets of readings of pressures and

temperatures (two different water flow rates).

8. Keep the evaporator saturation temperature constant b adjustment of the

evaporator water flow rate and inlet temperature and run a series of tests

at 4, different condenser pressures (controlled by variation of condenser

water flow rate). The related.

9. With the tabulated values found in step 8, construct a performance curve

for the refrigeration Unit using Refrigerating Effect (Watts) vs. condenser

Saturation Temperature (0C) for a constant Evaporator Saturation

Temperature.

CONCLUSIONS:

1. Are the heat transfer coefficients at the condenser and evaporator

constant at different pressures and temperatures?

2. What is the relation between the refrigerating effect and the pressure

ration (condenser pressure/ratio? pressure)? To get the largest

refrigerating effects from a given unit, what should be the pressure ratio?

3. What do you think are the reasons why R11 refrigerant is used in this

demonstration unit?

WEEK 8

OBJECTIVE:

To determine the coefficient of performance of the Air-conditioning test unit when

acting as:i.

A cooler

ii.

A heat pump

EQUIPMENT

Plint and partners versatemp air-conditioning TE/94/1902, flowmeter, cromption

wattmeter, thermometers.

Student to draw a schematic diagram of the arrangement.

PROCEDURE

Students to write this up as per instructed

THEORY

Conventionally, the air-conditioners is described as a cooler when it is extracting

heat from the surrounding air and rejecting it to the cooling water; and it is

described as a heat pump when it is extracting heat from the water and transferring

it to air.

(i)

The coefficient of performance of the air-conditioning when acting as a

cooler is given by

CPR =

q1

W

Where q1 = heat extracted from air

= mass flow rate of air x Enthalpy drop of air in passing through airconditioner.

Mass flow rate of air can be calculated from the pitot tube mounted in the

discharge duct;

But

Pa

=

RT

P

Where

R

=

287

Pa

=

atmospheric pressure in N/m2.

The velocity of the air U, corresponding to the velocity head H1 cm H2O as

measured in the pitot tube is given by

U2

=

98.1 H1

2

From these, it can be found that the mass flow rate of the air

m1

=

0.00332

H1 Pa

kg/sec.

T2

Where T2 = temperature of the air leaving air – conditioner (0K)

q1 =

m1 CP (T1 – T2)

Where T1 = temperature of air entering air-conditioner

CP = specific heat of air at constant pressure

= 1.005 kj/kg 0K.

W = Power input by fan + compressor + heat gained by water in cooling

refrigerant.

Heat gained by cooling water

=

m2 CP (T5 – T4)

Where CP = 4.19 kj/kg 0K.

From the rotameter the volume of circulating water can be observed and hence the

mass; take the density of water as:(ii)

The coefficient of performance of the air-conditioner when acting as a

heater.

CPH =

q2

w

where q2 = energy gained by air in passing through air-conditioner.

W = power input to fan + compressor + heater

EXPERIMENTAL DATA

TEMPERATURE OF INCOMING AIR.

TEMPERATURE OF OUTGOING AIR

PITOT TUBE DEFLECTION

POWER INPUT TO FAN

POWER INPUT TO COMPRESSOR

POWER INPUT TO HEATER

TEMPERATURE OF WATER AT INLET

TEMPERATURE OF WATER AT OUTLET

RATE OF FLOW OF WATER

BAROMETRIC PRESSURE

CONCLUSION

i.

From standard calculations, the maximum coefficient of performance of

the air-conditioner as a cooler was found to be 6.2.

Compare and

contrast this with your results.

ii.

The maximum coefficient of performance of this air-conditioner as a

heater was also found to be 4.78. Compare and contrast this with your

results.

WEEK 9

OBJECTIVE:

To determine the coefficient of performance of the Air-conditioning test unit when

acting as:i.

A cooler contd

ii.

A heat pump contd

EQUIPMENT

Plint and partners versatemp air-conditioning TE/94/1902, flowmeter, cromption

wattmeter, thermometers.

Student to draw a schematic diagram of the arrangement.

PROCEDURE

Students to write this up as per instructed

THEORY

Conventionally, the air-conditioners is described as a cooler when it is extracting

heat from the surrounding air and rejecting it to the cooling water; and it is

described as a heat pump when it is extracting heat from the water and transferring

it to air.

(i)

The coefficient of performance of the air-conditioning when acting as a

cooler is given by

CPR =

q1

W

Where q1 = heat extracted from air

= mass flow rate of air x Enthalpy drop of air in passing through airconditioner.

Mass flow rate of air can be calculated from the pitot tube mounted in the

discharge duct;

But

Pa

=

RT

P

Where

R

=

287

Pa

=

atmospheric pressure in N/m2.

The velocity of the air U, corresponding to the velocity head H1 cm H2O as

measured in the pitot tube is given by

U2

=

98.1 H1

2

From these, it can be found that the mass flow rate of the air

m1

=

0.00332

H1 Pa

kg/sec.

T2

Where T2 = temperature of the air leaving air – conditioner (0K)

q1 =

m1 CP (T1 – T2)

Where T1 = temperature of air entering air-conditioner

CP = specific heat of air at constant pressure

= 1.005 kj/kg 0K.

W = Power input by fan + compressor + heat gained by water in cooling

refrigerant.

Heat gained by cooling water

=

m2 CP (T5 – T4)

Where CP = 4.19 kj/kg 0K.

From the rotameter the volume of circulating water can be observed and hence the

mass; take the density of water as:(ii)

The coefficient of performance of the air-conditioner when acting as a

heater.

CPH =

q2

w

where q2 = energy gained by air in passing through air-conditioner.

W = power input to fan + compressor + heater

EXPERIMENTAL DATA

TEMPERATURE OF INCOMING AIR.

TEMPERATURE OF OUTGOING AIR

PITOT TUBE DEFLECTION

POWER INPUT TO FAN

POWER INPUT TO COMPRESSOR

POWER INPUT TO HEATER

TEMPERATURE OF WATER AT INLET

TEMPERATURE OF WATER AT OUTLET

RATE OF FLOW OF WATER

BAROMETRIC PRESSURE

CONCLUSION

i.

From standard calculations, the maximum coefficient of performance of

the air-conditioner as a cooler was found to be 6.2.

Compare and

contrast this with your results.

ii.

The maximum coefficient of performance of this air-conditioner as a

heater was also found to be 4.78. Compare and contrast this with your

results.

WEEK 10

TROUBLE SHOOTING: Self-contained Mechanical Refrigerators

Symptom

Possible cause

A) Power at point but unit will a) Thermostat improperly set or

not start

defective

b) Compressor overloads open circuit

c) Wiring defect

B) Compressor hums and trips

on overload

a) Low voltage

b) Defective capacitor

c) Defective relay (not closing)

d) Defective compressor

C) Compressor short-cycles

e) Liquid refrigerant in compressor

a) Defective compressor overload

b) Thermostat defective

c) Condenser airflow restricted.

d) Air in system

Remedial action

a) Reset or test and replace thermostat

b) Test, repair or replace Klixon

c) Check wiring for connections and continuity; adjust as

necessary

a) Check voltages at power point and at terminal box

b) Test and replace if necessary

c) Check relay operation and replace if necessary

d) Check for mechanical operation - replace if piston etc.

is jammed

e) Fit crankcase heater and/or accumulator

a) Test, repair or replace Klixon

b) Test, replace if necessary

c) Check cleanliness of condenser - remove any

obstructions to correct airflows

d) Test, purge, repair leak and recharge system

e) Check liquid line for damage and replace if necessary

f) Replace strainer/drier and capillary tube

e) Liquid-line damage

g) Replace capillary tube and strainer/drier

f) Liquid-line filter blocked (filter

frosts over)

g) Capillary tube blocked or damaged

(frost back along capillary possible)

TROUBLE SHOOTING: Self-contained Absorption-Type Refrigerator

Symptom

A) No or poor cooling

efficiency

Possible cause

Remedial action

a) Gas jet burner or heating element

defective

b) Thermostat defective

c) Door gasket faulty or door not sealing

properly (condensation around door,

evaporator coated with watery ice)

d) Loss of refrigerant charge (faint smell

of ammonia)

e) Poor condensing efficiency

a) Strip, clean and check correct operation; replace wick

etc. if required

b) Check operation, replace if necessary

c) Check door seal and gasket fit - replace as necessary

d) Fit new cooling system

e) Check condenser for cleanliness and remove any obstructions to

free airflow

10.4 Walk-in Refrigerators

Symptom

A) Temperature high - coil

heavily frosted

Possible cause

a) Defective door gasket

(condensation around door)

b) Inadequate defrost cycle

c) Excessive loading

Remedial action

a) Check, replace if necessary; investigate loading methods

b) Examine time clocks, heating elements and

safety controls or reverse cycle defrost valves

as fitted; if all is in order, check that coil is free

from frost at end of cycle (time) and speed of ice

build-up (frequency) and reset controls as

necessary

c) Investigate pattern of usage and control settings if product is held

near its freezing point

WEEK 11

TROBLE SHOOTING: Air handling Units - General

Symptom

A) Evaporator fan motor runs - no

cooling or heating

B) Evaporator fan motor runs insufficient cooling or heating

C) Excessive noise

Possible cause

a) Controls not properly set

b) Defective thermostat

c) Starting sequence interlocks not

completed

d) System wiring defect

e) Safety control open circuit

a) Blocked evaporator airflow

b) Defective evaporator fan or fan drive

a) Pipes vibrating and making metal to

metal contact

b) Evaporator fan touching blower

housing

c) Fan shaft out of alignment

d) Fan drive defect

e) Fan out of balance

f) Anti-vibration isolators worn or

defective

g) Faulty installation - unit not

properly level

Remedial action

a) Check and reset

b) Check and reset

c) Locate and correct wiring or control defect

x

d) Locate and remedy fault

e) Locate and remedy cause of control operation

a) Check grilles for obstructions, condition of cooling coil and air

filter; clean and adjust as

necessary

b) Check fan tight on shaft and rotates freely; inspect belt tension and

condition; adjust or

replace as necessary

a) Adjust pipe positions

b) Reposition and tighten fan(s) on shaft

c) Test, replace if necessary

d) Check belts for wear, tension and alignment; check bearings and

pulleys

e) Rebalance or replace

f) Replace as necessary

g) Check levels, adjust or correct as necessary

A) Evaporator fan runs

compressor will not start

B) Evaporator fan runs Insufficient cooling Compressor runs

continuously

C) Evaporator fan runs Insufficient cooling compressor short-cycles

a) Compressor electrical interlocks not

completed

b) Compressor safety control open

circuit

c) Defective compressor

c) Check, and replace if necessary

a)

b)

c)

d)

a)

b)

c)

d)

Controls not properly set

Shortage of refrigerant

Compressor not pumping

TEV jammed open

e) Excessive heat load

f) Flash gas in liquid line - low ambient

temperature

a) Low voltage

b) Controls not properly set

c) Air in system

d) Inadequate condensing

e) Defective compressor contact or

windings

f) Compressor safety control open

circuit

g) Inadequate evaporator airflow

h) Liquid-line blockage

i) 'Over condensing' j)

Shortage of refrigerant

a) Locate and remove cause

b) Locate and remove cause

Check and reset

Check via sight glass - top-up charge, leak test

Test, replace if necessary

Strip, clean or replace

e) Check for structural or equipment causes

f) Fit head pressure controller

a) Check voltage at mains isolator and compressor

terminals with unit running

b) Check and adjust

c) Purge, repair leak, top up refrigerant charge

d) Check condenser fan operation and for freedom from

blockages

e) Check connections and operation - replace parts as

necessary

f) Check all control settings and operation, or locate

and remedy cause if external

g) Check for blockages of air filters, cooling coil, air

passages; check condition of fan and drive kit

h) Check condition of filter/drier, solenoid valve

and TEV; check that TEV phial is properly

secured and has not lost its charge

Fit head pressure controller

Check at sight glass, leak test, repair leaks if

found, top-up refrigerant

Air handling Units - Direct Expansion

Symptom

D) Low suction pressure

Possible cause

a) Expansion valve defect - seat or

superheat setting

b) Evaporator airflow incorrect

c) Shortage of refrigerant

d) 'Over condensing' - low ambient

temperature

e) Incorrect control setting

f) Partial obstruction of liquid line

g) Flash gas in liquid line - no leaks in

system

Remedial action

a) Systematically check TEV operation, clean or replace or adjust as

necessary

b) Check fan tightness, drive kit condition, absence of restrictions to

airflow

c) Check at sight glass, leak test, repair leaks, top up with refrigerant

d) Fit head pressure controller

e) Check control settings and operation

f) Check condition of filter/drier and solenoid valve

g) Check height of liquid-line risers and degree of sub cooling in

condenser

WEEK 12

TROBLE SHOOTING: Thermostatic Expansion Valves

Possible cause

Symptom

A) Low suction pressure high

superheat

S) Low suction pressure low superheat C) High

suction pressure

low superheat

D) Suction pressure

fluctuates ('Hunting')

a)

b)

c)

d)

e)

Low ambient temperature

Loss of refrigerant

Equalizer line blocked

Orifice blocked by wax, oil or dust

Superheat setting too high

a) Incorrect superheat setting

b) Valve seat held open by dirt, oil etc.

c) Equalizer line blocked

d) Bulb not properly fixed

a) Incorrect superheat setting

b) Uneven load at evaporator

c) Equalizer line restricted

d) Oil in suction line affecting

temperature sensed by valve bulb

Remedial action

a)

b)

c)

d)

e)

f)

Fit head pressure control

Trace and repair leak, recharge

Repair or replace line

Strip and clean valve; fit new filter/driers

Adjust setting

Replace valve power element

a) Adjust setting

b) Clean valve, fit new filter/drier

c) Clean or replace line

d) Check that bulb is securely clamped to suction line and

is not affected by other heat sources

a) Adjust setting

b) Check condition of distributor

c) Clean or replace line

d) Do not locate valve sensing element in a section of line

likely to form an oil trap

TROBLE SHOOTING: Solenoid Valves

Symptom

Possible cause

Plunger stuck by solids or oil

Valve body warped

Solenoid coil burnout

Faulty electric connections

Excessive refrigerant pressure

Remedial action

A) Valve will not open

a)

b)

c)

d)

e)

B) Valve will not close

C) Valve closes but flow

continues

a) Plunger stuck by solids or oil

b) Spring broken or stuck

c) Electrical fault

a) Strip and clean valve

b) Strip valve, replace spring

c) Check all contacts and electric connections

D) Valve noisy

a) Contaminants under valve seat

b) Seat or pin damaged

a) Strip and clean

b) Replace damaged item(s)

a) Incorrect assembly

b) Refrigerant noise

c) Flash gas in liquid line

b) Check and tighten components

b) Install discharge muffler

c) Check refrigerant charge and liquid-line

strainer/drier; check whether head pressure

control is necessary

d) Check coil sleeve for fit and overall valve

cleanliness

d) Electric hum

E) Coil burned out

a) High or low voltage

b) Wiring defect

c) Moisture entered coil

d) Plunger jammed

a)

b)

c)

d)

e)

Strip and clean valve

Replace body

Remedy cause and replace spring

Check all contacts and electric connections

Locate and remove cause

a) Check and remedy

b) Check all contacts and electric connections

c) Protect from drips and electrically seal all

connections

d) Strip and clean valve when fitting new coil

WEEK 13

TROBLE SHOOTING: Chilled-Water Air handling Units

Symptom

A) Insufficient cooling

Remedial action

Possible cause

a) Insufficient chilled water supplied to

cooling coil

b) Chilled-water flow switch open circuit cooling system inoperative

c) Restricted airflow over cooling coil

d) Excessive cooling load

e) Internal scaling of chilled water system

a) Incorrect control setting

B) Overcooling of space

b) Excessive chilled water flow rate

b)

Refer to

a) Check setting and operation of controls, and

Ch. 8

chilled water valve(s)

10.18

b) Locate reason for operation of safety control, and restart

system; if no other defect is apparent, check the flow switch

itself Systematically check through air filter condition, and

c) the cooling coil cleanliness; check fan operation, belt tension

and alignment, and shaft bearing condition

d) Check conditioned space for open doors, windows etc;

or for the use of additional heat generating equipment

e) Test pressure drops through cooling coil and

Ch. 8

water chiller; if it is excessive, clean entire

circuit chemically; recharge chilled water system

and add a charge of a scale-inhibiting chemical

a) Check and reset as necessary with particular reference to

thermostat, water valve linkage and valve operation

Check controls as at (a) above; test water

Ch. 8

volumes through coil and if necessary adjust

and rebalance system water distribution

WEEK 14

TROBLE SHOOTING: Air handling Units - Electric Heating Coils

Symptom

A) Insufficient or no heating

effect

Possible cause

a) Controls not properly set

b) Control defect

c) Restricted airflow over heating coils

d) Defective heating elements

e) Heater safety switch faulty or open

circuit

f) Unit wiring defect

g) Evaporator fan or fan drive defect

B) Overheating of space

a) Controls not properly set

b) Controls defective

Remedial action

a) Check and reset

b) Systematically check contacts and operation of operating controls;

adjust or replace items as required

c) Check air filters, cooling coil, supply and return grilles for freedom

from obstructions

d) Check all elements for electrical continuity and where necessary

e) Check safety switch for correct operation; if this is in order check

out and remove cause of operation; if defective, replace safety

switch

f) Check conductors, connections etc. against wiring diagram

g) Check fan tight on shaft and rotates freely; check tension,

alignment and condition of fan

motor belts, and tightness of pulleys; check

bearings

a) Check setting of thermostat etc.

b) Systematically check contacts and operation of

thermostat; adjust or replace as necessary

Air handling Units With Humidifiers

Symptom

A) Humidity too low

Possible cause

a) Controls not properly set

b) Defective control

c) Excessive scale in humidifier

d) Humidifier undersized for

operating conditions

e) System wiring defect

f) Cooling system defect

B) Humidity too high

a) Controls not properly set

b) Defective control

Remedial action

a) Check and adjust

b) Check control circuit operation and condition of electric

contacts, replace as necessary

c) Replace or descale, in accordance with

instructions for the specific type used

d) Recalculate needs and if necessary arrange for a booster

humidifier to be fitted

e) Check all wiring, contacts and fuses

f) Check air temperature off cooling coils; if it is too low

proceed as instructed, in section on direct expansion

or chilled-water coils, as applicable

a) Check and adjust

b) Check control operation, and state of electric contacts;

replace as necesary

WEEK 15

TROBLE SHOOTING: Condensing Units (General)

Symptom

Possible cause

A) Compressor motor will not a) No power at terminals start

b) Power arriving at motor terminals

B) Compressor short-cycles

a) Incorrect control or safety device

setting

b) Restrictions in liquid line

c) Shortage of refrigerant

d) Refrigerant overcharge

e) Insufficient cooling duty

C) Compressor runs

non-stop

f) Over condensing - flash gas in liquid

line preventing proper start-up

a) Excessive cooling duty

b) Incorrect operating control settings

c) Defective compressor refrigerant

suction/discharge valves

d) Faulty refrigerant flow

D) Suction line frosts back to

180compressor

a) Insufficient cooling duty

Remedial action

Refer to

a) Check mains supply, fuses, control settings and Ch. 12 terminals,

and interlocks

b) Check pressure and thermal overloads - adjust Ch. 12 them, or

trace and remove cause of operation; test motor insulation and

winding continuity, and freedom from mechanical seizure; if

necessary, replace compressor

a) Check and reset as necessary

b) Check solenoid valve, TEV, filter/drier and

10.7

piping itself

10.8

c) Check at sight glass, top-up charge, leak test,

Ch. 8 repair

leaks

d) Check discharge pressure variations during

Ch. 11

off-cycle, purge any air from high side of

condenser

e) Investigate load at evaporator; if necessary fit

10.15 hot gas

bypass system

f) Check temperature of air onto (or water into)

Ch. 6

condenser, and cooling requirements; if

necessary fit head pressure controller

a) Check and if possible remove cause of excess load (open

doors or windows etc. or use of extra heat-producing

appliances)

b) Check and reset as necessary

c) Test compressor pumping efficiency and

Ch. 11

maintenance of pressures during off-cycle;

replace if necessary

d) Check for leaks, defective TEV operation or

10.7

superheat setting, and phial fastening; check

10.8

solenoid valve operation and filter/drier

condition

a) Investigate load at evaporator; if necessary fit hot gas

bypass system

TROUBLE-SHOOTING

Condensing Units (General)

Possible cause

Symptom

a) Faulty external mountings

b) Unit jumped off internal spring

mountings

c) Damaged valve reeds etc.

d) Liquid slugging

I) Compressor excessively noisy

F) Head pressure too high

a) Overcharge of refrigerant

b) Air in system

c) Inadequate condenser

performance

a)

Shortage

of

refrigerant,

or restricted liquid line

Q) Head pressure too low

b) Insufficient cooling load

c) Over condensing

d) Hot gas bypass valve wrongly set

e) Defective compressor discharge

valve H) Suction pressure

too high a) Excessive cooling load

b) TEV setting or operation faulty

c) Defective compressor suction

valve

I) Suction pressure too low

a) Shortage of refrigerant, or

liquid-line restriction

b) Hot gas bypass valve not correctly set

c) Excessive pressure drop through

evaporator

d) Restriction at evaporator of air or water

to be cooled

Condensing Units (Air-cooled)

Remedial action

a) Check, replace as necessary

b) Replace compressor

c) Replace compressor

d) Check and adjust TEV superheat setting, and cooling duty at

evaporator; check evaporator free from restrictions

a) Purge off excess

b) Verify through check of pressure during off-cycle; purge air

c) Check flows of air or water and ensure that condenser

cooling surfaces are clean

a) Check at sight glass; and condition of strainer/drier, solenoid

valve and TEV 10.8

b) Check condition of evaporator and air filters in DX

(direct expansion) units

c) Check entering temperature of cooling medium; necessary fit hot

gas bypass system

d) Check and adjust

e) Check pumping efficiency, if necessary replace

a) Check evaporator duty

b) Check, adjust or replace TEV as necessary

c) Check pumping capacity and replace if, necessary

a) Check at sight glass; then if necessary conditions of filter/drier,

solenoid valve and TEV; top up, adjust or replace as necessary

b) Test and adjust as necessary

c) Check and adjust TEV superheat setting as necessary

d) Check air/water volumes over evaporator and

performance/condition of fans, filters, pumps etc;

clean or adjust as necessary

Symptom

Possible cause

Remedial action

A) Low discharge pressure

a) Low ambient temperature

a) Check settings and operation of head pressure

controller and dampers if fitted; adjust or replace as

necessary

B) High discharge pressure

a) High ambient temperature

b) Condenser airflow restricted

a) As at (a) above

b) Remove any obstructions to airstreams; check

condenser fins not choked by dirt, clean as necessary

c) Check condition and tightness of fan - belt tension,

alignment and wear - freedom of shaft - motor

operation

d) Check no short-cycling of air between adjacent units no exposure to heat from other equipment

c) Condenser fan drive defect

d) External influences