INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL Volume 2, No 1, 2011 © Copyright 2010 All rights reserved Integrated Publishing Association CASE STUDY ISSN ­ 0976­4259 Enterprise Resource Planning (ERP) of Canteen using USA Principle: A case study Gadakh. V. S 1 , Mawale. M. B 2 1­ Department of Mechanical Engineering, Amrutvahini College of Engineering, Sangamner, Ahmednagar, Maharashtra– 422 608, India 2­ Kavikulguru Institute of Technology & Science, Ramtek, Maharashtra ­ 441 106, India gadakh_vijay@mec.vnit.ac.in ABSTRACT In today’s scenario, the solution to some system with the aid of Enterprise Resource Planning (ERP) software point of view is very common. Generally it is applicable where the resources are plenty and evaluation of these resources are quite complex. But if the resources are less then it is not affordable to the system due to cost criteria of the software. The ultimate goal of any system is to manage the resources by any means. In this work, a case study of service & process industry i.e. VNIT College Canteen is considered for ERP implementation using Understand­Simplify­Automate (USA) Principle. Keywords: ERP, USA Principle, TRIZ, Product Development. 1. Introduction To survive and grow in a present competitive global market scenario, it is necessary for the industry to continue delivering consistently high quality products and services to its customers. In today’s competitive world when the industries are talking about the global market, the resources handled by an industry are tremendous. For any enterprise, to be successful it is very important that how efficiently these resources are planned. Today for any industry it is observed that if the resources are available in plenty, it is tendency of human beings to waste them. So at one end we are using computers in the technical field to make ourselves perfect in the engineering field, but if one pays no attention in making the best use of whatever is produced this computer implementation has any meaning. The available ERP package includes SAP, AG, Baan, People Soft etc. These softwares are widely used in the large scale or even medium scale industries. But how to manage the resources of a small scale industry? The objective ERP covers the effective use of management resources to improve the efficiency of the organization. So in this work, a case study of service & process industry i.e. VNIT College Canteen is considered for Enterprise Resource Planning (ERP) implementation (Gadakh, V. S, 2008). Here we have applied the principle of USA for the improvement of Canteen. USA principle means: 1. Understand the existing process 2. Simplify the process 3. Automate the process

183 INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL Volume 2, No 1, 2011 © Copyright 2010 All rights reserved Integrated Publishing Association CASE STUDY ISSN ­ 0976­4259 The USA principle is a common sense approach to automation projects. It is so general that it is applicable to nearly any automation project. Going through each step of the procedure for an automation project is not necessary (Groover, M. P, 2007). In a canteen the resources involved are as: i.e. 3P’s 1. People 2. Process 3. Product Our aim in implementation of this principle is to optimize these resources, with existing availability of the funds. That is to plan the best possible use of whatever is available. The following data were collected from the canteen. 2. Understand the existing structure of an organization The purpose of the first step in the USA approach is to comprehend the current process in all of its details. One may use basic charting tools such as operation process chart and flow process chart. As these tools provide a model of the process that can be analyzed and searched for weaknesses (& strengths). Similarly, mathematical models of the process may also be useful to indicate relationship between input parameters and output variables. 1. People working At present the organization having 8 to 9 persons inclusive of Cooks, Waiters, Cleaners and the Owner. 2. Nature of Industry Service & process­industry (canteen) 3. Material The raw material is procured from market. The material procurement is carried out depending upon the type of the material required by the organization. The items with shorter shelf life are procured on a daily basis this includes green vegetables, milk and milk products like curd etc. The other items with probably longer life such as bread, eggs etc are procured alternate day and items like the groceries and other consumables like oil spices condiments flour are procured monthly. 4. Arrangement or layout It is the hub of entire activity; therefore it must be spacious enough to accommodate extra cooks during the rush hours. The space for cooking is restricted with the ‘L’ shape of the kitchen all the items are haphazardly arranged. The seating arrangement for the customers is also in a very haphazard manner. Therefore it is very difficult for the waiters to serve the customer and this is a major hurdle for late servings for the customer order.

184 INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL Volume 2, No 1, 2011 © Copyright 2010 All rights reserved Integrated Publishing Association CASE STUDY ISSN ­ 0976­4259 5. Storage The raw material and other partially processed food items need to be stored properly to avoid the wastage in general and use the existing resources to their fullest capacity. 6. Salaries The salaries offered to the people working here ranges from Rs.1, 500 to 4,500. The salaries were depends upon the nature of work done. 7. Problem of customer arrival It is a Canteen; therefore there is no fixed time of arrival of customer. Therefore there is a major problem of material order. Sometimes the cook has to make some foodstuff 2 to 3 times or sometimes he may even not have to make them at all. That means there is no fixed analysis of demand and supply. The rush hour is observed between 7.00 AM to 10.00 AM and during the lunch break and in the evening right from 4.00 PM up to the closing time. e. g. sometimes the cook have to make 2 to 3 sets of samosas depending upon the seasonal changes or sometimes nobody eats samosas. 8. Market Rate The rates which are displayed there in the canteen are of six to seven years back. During this period the raw material prices like existing prices of vegetable oil and vegetables and other related items have swollen up. The rates are fixed by the tender while at the start of the contract. 3. Simplfy the process Once the existing process is understood, then search can begin for ways to simplify. This step involves a checklist of questionnaire about the existing process. Based on the above data collected we have tried to suggest the improved way to utilize the existing resources in a more efficient manner.

· The raw material which is used for the producing the items must be stored properly in the shelves with suitable kind of shelving done. There can be designed suitable shelves just at the height of the cook above his worktable. So that everything is well within his reach and he can do his work standing at one place only i.e. ergonomics consideration?

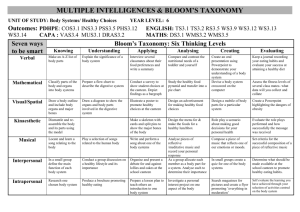

185 INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL Volume 2, No 1, 2011 © Copyright 2010 All rights reserved Integrated Publishing Association CASE STUDY ISSN ­ 0976­4259 Figure 1: Existing Layout of the Kitchen Figure 2: Proposed Layout of the Kitchen

186 INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL Volume 2, No 1, 2011 © Copyright 2010 All rights reserved Integrated Publishing Association CASE STUDY ISSN ­ 0976­4259 · The existing capacity of the seating arrangement proves quite inadequate in handling the number of crowd at that place so the layout of the place needs to be well designed with the seating and the other arrangements to be made in systematic way as mentioned below. It is observed that there are three doors to the canteen, so the best possible options would be to arrange the seating arrangements within the four quadrants of the premises. This would provide enough space for the waiters to move within the tables to serve the customers in a more proper and efficient way. Figure 3: Modified seating arrangement

· In the organization the categorization of the staff is to be done based on their need of work, like: 1. Cook 2. Waiter 3. Cleaner When this type of categorization is done it will be more useful for the owner to distribute the wages.

· The organization is in bad need of a refrigerator of larger capacity (preferably a deep freezer) which is required for the storage of perishable food items. The existing refrigerator proves to be small in size and with growing demand of the people incoming the orders also increase. Therefore a single refrigerator proves quite inadequate.

187

INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL Volume 2, No 1, 2011 © Copyright 2010 All rights reserved Integrated Publishing Association CASE STUDY ISSN ­ 0976­4259 · Self service can be implemented so that the customer will collect his/her order from the counter itself which may results in the reduction of employee (at least two numbers). 4. Automate the process Once the process has been reduced to its simplest form, then automation can be considered. As previously discussed, going through each step of the procedure for an automation project is not necessary. So, this step can be a future scope of the project. The proposal is to have an automated token system, and to implement self service inside the canteen. This would work as follows. As soon as the customer has paid the money, he would get a token no and he would sit in his place. As soon as the order is ready him/her number would be announced on the respective counter and he would have to go to the counter and collect his order. This would avoid a long queue in front of the counter. This would help greatly to reduce the no of employees and the service quality can be improved. With the introduction of this system it is possible to know the exact number of customers arriving at each day, date and thus it is possible for us to calculate the trend of the customer inflow. Also this system allows faster service to the customer as the cooks get to know the order instantly as soon as he receives the token from the customer no time is lost in preparing the order. Then the system performance can be further improved by having more than one cooks who would work simultaneously on more than one order. Figure 4: Digital Token System­Future Scope 5. Conclusion In this study the implementation of ERP by using USA principle is considered. The aim in implementation of this principle is to optimize the resources, with existing availability of the funds. That is to plan the best possible use of whatever is available. The USA principle is a

188

INTERNATIONAL JOURNAL OF APPLIED ENGINEERING RESEARCH, DINDIGUL Volume 2, No 1, 2011 © Copyright 2010 All rights reserved Integrated Publishing Association CASE STUDY ISSN ­ 0976­4259 common sense approach to automation projects. It is so general that it is applicable to nearly any automation project. Here it is to be mentioned that going through each step of the procedure for an automation project is not necessary. Acknowledgements The authors would like to thank owner of the VNIT College canteen for providing sufficient details. Authors special thanks to Prof. A. M. Kuthe for his constant help and support for making such kind of work. 6. References 1. Gadakh, V. S., and Mawale, M. B. ((2008),Lecture notes on Product Design and Development. M. Tech. CAD/CAM, 3rd sem, VNIT Nagpur, 2. Groover, M. P. (2007), Automation, Production Systems, and Computer­Integrated Manufacturing. Pearson Prentice Hall, 2 nd Edn. pp 33­34.

189