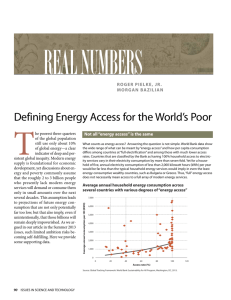

Worldwide Trends in Energy Use and Efficiency

advertisement