Analysis of Silver in an Alloy

advertisement

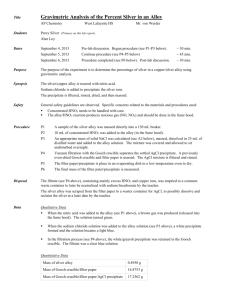

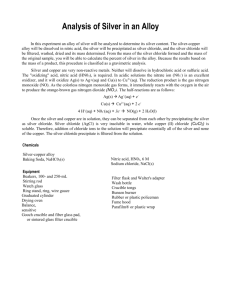

Analysis of Silver in an Alloy Introduction In this experiment an alloy of silver is analyzed to determine its silver content. The mass of the silvercopper alloy is measured. The alloy is then dissolved in nitric acid, the silver is precipitated as silver chloride, and the silver chloride is filtered, washed, dried and its mass determined. From the mass of the silver chloride formed and the mass of the original sample, the percent of silver in the alloy can be calculated. Because the results are based on the mass of a product, this procedure is classified as a gravimetric analysis. Silver and copper are very non-reactive metals. Neither will dissolve in hydrochloric acid or sulfuric acid. The “oxidizing” acid, nitric acid (HNO3), is required. In acidic solutions the nitrate ion, (NO3-) is an excellent oxidizer, and it will oxidize Ag(s) to Ag+(aq) and Cu(s) to Cu2+(aq). The reduction product is the gas nitrogen monoxide (NO). As the colorless nitrogen monoxide gas forms, it immediately reacts with the oxygen in the air to produce the orange-brown gas nitrogen dioxide (NO2). The half-reactions are as follows: Ag(s) → Ag+(aq) + eCu(s) → Cu2+(aq) + 2e+ 4H (aq) + NO3-(aq) + 3e- → NO(g) + 2H2O(l) Once the silver and copper are in solution, they can by separated from each other by precipitating the silver as silver chloride. Silver chloride (AgCl) is very insoluble in water, while copper (II) chloride is soluble. Therefore addition of chloride ions to the solution will precipitate essentially all of the silver and none of the copper. The silver chloride precipitate is filtered from the solution, dried, and its mass determined. Chemicals Silver-copper alloy Baking Soda, NaHCO3(s) Nitric Acid, HNO3, 6M Sodium chloride, NaCl(s) Equipment Beakers, 100- and 250- mL Stirring rod Watch glass Ring stand, ring, wire gauze Graduated cylinder Drying oven Balance, sensitive Gooch crucible and fiber glass pad, or sintered glass filter crucible Filter flask and Walter’s adapter Wash bottle Crucible tongs Bunsen burner Rubber policeman Fume hood Parafilm© Procedure Prepare a Filter Crucible To filter the solution, either a Gooch crucible or a sintered glass filter crucible will be used with a filter flask. Refer to Figure 1 below to see how the crucible, Walter’s adapter, and filter flask are assembled. If you use a Gooch crucible, clean it, place a fiber glass filter pad in the crucible and pull distilled water through the assembly to be sure the filter pad is seated tightly on the bottom of the crucible. If you are using a filter crucible, clean it and rinse it with distilled water using suction. Place the Gooch or sintered Adapted from “Laboratory Experiments for Advanced Placement Chemistry”; Vonderbrink; Flinn Scientific Inc; 2001 Analysis of Silver in an Alloy glass filter crucible in a clean beaker and dry it in an oven at 110°C. When the crucible is dry, cool it, and determine its mass using a sensitive balance. Be careful to handle the crucible so that no fingerprints will be present. Crucible Walter’s Adapter Filter flask Connect to aspirator on faucet Figure 1. filter flask with crucible and adapter Find the Mass of the Alloy Obtain a sample of silver alloy that is between 0.1 and 0.5 g. Determine its mass precisely on a sensitive balance. Dissolve the Silver Put the alloy in a clean 100-mL beaker, and carefully pour 10 mL of 6M nitric acid over it. Cover the beaker with a watch glass so none of the solution spatters out. It may be necessary to gently heat the solution so that the alloy dissolves. Allow the alloy to totally dissolve. Precipitate the Silver Calculate the amount of sodium chloride that would be necessary to precipitate the silver in your sample, assuming that the sample is 100% silver. Use a balance sensitive to +/- 0.01 g to weigh out two times the amount of sodium chloride. Dissolve the sodium chloride in 25 mL of distilled water. Remove the watch glass from the first beaker, and rinse any moisture on the bottom of the watch glass back into the beaker with your wash bottle to be sure that no silver is lost. To precipitate the silver as silver chloride slowly add the sodium chloride solution to the dissolved silver. Stir with a stirring rod, and use distilled water to rinse any solution clinging to the rod back into the beaker. Gently heat (without boiling) the solution for about 15 minutes. This will cause the precipitate particles to grow larger so they are easier to filter. Alternatively, cover the beaker with Parafilm© or plastic wrap and allow it to stand overnight. This will also allow the particles to grow larger. Filter the Silver Chloride Attach the filter crucible to a suction flask. Pour some distilled water through the filter with suction to be sure that the filter pad firmly seals the bottom of the Gooch crucible. In your wash bottle, add 2 mL of 6 M HNO3 to 150 mL of distilled water. Label your wash bottle appropriately. Use this as a rinse. The addition of the acid to the rinse water helps to keep the precipitate from “Peptizing,” or forming extremely small particles that will run through the crucible. Wash the precipitate into the crucible with the dilute nitric acid solution. Be sure to get every particle! A rubber policeman on a stirring rod can be used as a squeegee to clean the sides of the beaker. Rinse the precipitate several times with the wash solution. Adapted from “Laboratory Experiments for Advanced Placement Chemistry”; Vonderbrink; Flinn Scientific Inc; 2001 Analysis of Silver in an Alloy Dry the Silver Chloride and Determine Its Mass Put the crucible with silver chloride in a clean beaker, cover it with a watch glass, and let it dry in the oven at 110 °C for at least 30 minutes. When it is dry and cool, find its mass on the analytical balance. If you have time, dry it an additional 30 minutes and again determine its mass to see if it reached a constant value. Calculate the Percent Silver in the Alloy From your data, determine the percent of silver in your sample. Disposal The solid silver chloride and the filter pad may be placed in the waste container in the back. The solution is to be placed in the Waste Beaker on the front table. Place the crucible on the front table. Discussion Questions 1. Explain how the percent of silver would be affected by the following: a. The alloy was not allowed to dissolve completely. b. The silver chloride was not completely dry when weighed a final time. c. Fingerprints added mass to the original sample. d. Too much sodium chloride was used. e. Not enough sodium chloride was used. f. The precipitate was not washed thoroughly. 2. Why don’t we use hydrochloric acid to both dissolve and precipitate the silver? Adapted from “Laboratory Experiments for Advanced Placement Chemistry”; Vonderbrink; Flinn Scientific Inc; 2001