Article 5 - APICS

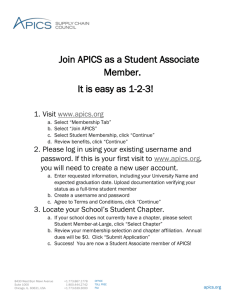

advertisement

Taking — and Passing — “the Test”: A Series on APICS Certification by Pete Stonebraker, Ph.D. CPIM Course-by-Course Strategies in Test Preparation (#2) Article #5 in the Series This is the fifth article in the Series on “APICS Certification”. In the first article, suggestions on appropriate test-preparation activities are discussed, and in the second article the foundations of the APICS body of knowledge are identified. In the third article, a number of very specific, tactical approaches to preparing for taking the test are identified. The fourth article considers specific test-taking strategies for the Basics of Supply Chain Management and the Strategic Management of Resources courses. This article similarly offers specific test-taking strategies for the remaining three modules of the CPIM program, the Master Planning of Resources, the Detailed Planning and Scheduling, and the Execution and Control of Operations modules. The fourth article in this series considers the “Entry Module” and the “Capstone Module” together because those modules both have a “global perspective” of the APICS body of knowledge. Alternatively, this article considers the “Business Process Modules”, which cover the core of manufacturing and distribution planning and decision-making processes. Master Planning of Resources (MPR) considers the mid- to long-range planning activities, while Detailed Scheduling and Planning (DSP) focuses the short- to mid-term planning activities, and Execution and Control of Operations (ECO) addresses the execution or delivery phase activities. This article will note several commonalities of the business process modules, then consider each separately. Again, the key focus of this article, as with the preceding articles in this series, is to identify direct and usable test-taking skills to improve test performance. The Business Process Modules Arguably, the single most important concept of the business process modules is the hierarchy of planning. This concept is called by a variety of names, including the Manufacturing Planning and Control System, and establishes a range of variously-named planning activities from the long-range to the short-range and execution time frames. The concept is based on several fundamental assumptions: 1) that there are interrelationships and interactivity of long-, mid-, and short-range planning activities and the execution of operations, 2) that the primary function of these activities is the balancing of available resources with demand requirements, or, stated differently, that scheduling and prioritization activities must be assessed by capacity validation activities, and 3) that longer run activities drive shorter-run activities, and good long- mid- and short-range planning reduces costs and avoids expediting during the execution phase. A second, and perhaps equally important, concept is the notion of integration. The hierarchy of planning is necessarily integrated in a variety of ways with external activities, through such mechanisms as sales and operations planning, distribution planning, financial planning and the like. This integration is mandated by the necessary cross-functional coordination and horizontal integration, as well as vertical integration, of the supply chain. For success, integration assumes openly communicated objectives and requirements across a variety of different functional and organizational perspectives. The assumption of this model is simply that we are all in the same boat, and that it is better pull together, rather than make waves. The third fundamental concept of the business planning module courses is that the planning hierarchy functions in corresponding ways in different production environments. Arguably, APICS materials are most focused toward the job shop environment, perhaps because of the emergence of many production systems from the job shop. But, these same concepts, with minor variations can be applied to a line and continuous, JIT, project management, and repetitive manufacturing. For example, the notion of lead-time management can be stated differently in a job shop (queue, set-up, run, wait, move), line and continuous (balancing), JIT (kanban), project management (network analysis), and repetitive (cycle time compression), but each of these approaches addresses lead-time offsetting and management. Master Planning of Resources Forecasting and error measurement is a key component of the MPR course. In fact, forecasting was, at one time, a stand-alone APICS CPIM course. Forecasting is, in most environments, the initial source of demand data, upon which long- and mid-range planning is based. An operations manager could easily identify some ten to twelve primary forecasting methods, and some four or five error evaluation methods; and when various weights, or factors, are included, the number of forecasting and error evaluation methods can increase to more than one hundred. The important conclusions here are that there are numerous forecasting and error evaluation methods, that method must be fit to the pattern of the data, and no method is best under all circumstances. Generally, level data are forecast and evaluated using one method, and trended data another, etc. The well-prepared test taker should be able to calculate simple forecasting and error evaluation models, to understand the basic concept underlying each model, and to note when a particular model would be appropriately used. In the MPR course, there are four types of specific planning activities, Sales and Operations Planning, Resource Planning, Master Scheduling, and Rough-cut Capacity planning. These activities are key to the balancing of demands against resources, and the test-taker should understand the basic concepts and methods of each. Certainly, level, chase, and compromise strategies, as well as load leveling should be considered. Additionally, the well-prepared test taker should be able to categorize these planning activities in several ways, such as time-frame, level of product planned, frequency of planning, etc. Product structure is a central component of the MPR course. In an effort to reduce the complexity of operations scheduling processes and amount of inventory, operations managers have moved toward modular product structures, assemble-to-order production environments, and repetitive (short cycle) type scheduling methods. These approaches permit the use of such techniques as the Final Assembly Schedule, Projected Available Balance, Available to Promise, and Production Forecasting. The well-prepared test taker should understand, be able to use, and calculate each of these techniques. A final key idea in the MPR course is the transition of a manufacturing order from a planned order, to a firm planned order, to a released order during free, flexible, and frozen time periods, based on planning and demand time fences. This is the primary responsibility of the Master Scheduler, and is a rather structured and complex process. The well-prepared test taker should understand the process and the conditions under which a variety of master scheduling decisions would be made. Detailed Scheduling and Planning Perhaps more than any other module, DSP focuses on inventory management, including classifications of inventory, types of demand, order review processes, lot-sizing decisions, safety stock, and inventory valuation. These concepts and calculations are the basis for numerous test questions. The well-prepared test-taker should be able to identify the various definitions and methods of inventory management, categorize them as to where and when used, and to do simple calculations. Arguably, the single most central scheduling and inventory management concept of APICS during its some 40+ years as a society has been MRP. MRP and CRP were previously separate modules, and a major component of the APICS mission in the early days was the training of personnel to prepare the punch card data for MRP systems of the day. Though current systems are much more complex, the basic MRP logic and screen or hard-copy presentations (the matrix) have not substantively changed. MRP defines a Master Production Schedule, and CRP validates or suggests adjustment of that schedule. The well-prepared test-taker should be able to identify the processes, evaluate the outcomes, and do the calculations of these models. Supplier relationships and procurement management are newer topics in the APICS body of knowledge, and suggest the importance of integrated supply chains. However, the fundamentals of dealing with external suppliers are little different than dealing with internal activities. Note that the internally-used ELS calculation is a minor variant of the externally-used EOQ calculation, and that the MRP planned order release process treats internal and external sources in generally corresponding ways. Thus, most processes and calculations of supplier management may be learned as minor variations of previously studied internal system management. Execution and Control of Operations Arguably, the most important concept of the ECO course is to balance three objectives: customer service, inventory investment, and scheduling efficiency. These items are called the “execution variables”, and involve a trade-off of inventory and scheduling costs versus customer service objectives. A variety of techniques have been developed to assist the operations manager to address this tradeoff, including JIT, lean manufacturing, short-cycle manufacturing and others. The well-prepared test-taker should understand the trade-offs of different decisions and how the application of different methods affects the overall tradeoff decision. A second important model of the ECO course is the plan, execute, measure, and correct model. This integrates the planning and execution shop floor activities with the measurement and correction models of quality control and continuous improvement. More specifically, this process includes, among others, shop packet information, scheduling priority rules, and shop reporting. The wellprepared test-taker should be able to use various of these methods and to understand where they would be best used, and what limitations or problems these methods have. Quality and continuous improvement initiatives is clearly a third central component of the ECO course. The materials include some ten to twelve different concepts and continuous improvement tools, such as the Taguchi Loss function, team management techniques, the Shewhart cycle, SPC, etc. Each of these approaches can be characterized by a minimum of three-to-five descriptors, as to how it functions, where it is used, etc. The well-prepared test-taker should be able recognize and differentiate these approaches. Conclusions In conclusion, this series of articles has been based on two premises. 1) That the APICS CPIM certification tests can be successfully completed by 90% or more of test-takers if they take a roughly 25 hour course and supplement that course with some 25 additional hours of self-preparation, and specifically focusing on several key knowledge and test-preparation skills. 2) That test-question preparation is not rocket science. The test question preparation committees use several techniques to develop examination questions which, if understood by test-takers, can clearly improve test-taking performance. These premises are valid in any testing process, including academic evaluation, practitioner certification, or even drivers license testing. Certainly, knowledgeable instructors and APICS-certified practitioners could supplement the key points in this series of articles. Some might find additional points to concentrate on, while others might reorder the emphases presented here. As such, this series of articles does not offer an infallible or absolute set of guidelines. Rather, it may serve as an initial point for further discussion of the test-preparation process. I would encourage the further development of this dialog because it benefits the testdevelopment process as well as the test-taking process, and ultimately, it benefits APICS and the American manufacturing and distribution community. To prospective test-takers, I wish you the very best in your preparation activities. Be patient with yourselves; achieving APICS certification is a notable career milestone and should not be expected to be accomplished rapidly, or without some notable effort and preparation. But, through this effort, you will personally and professionally benefit from the better understanding of the body of knowledge. Your job performance will be enhanced, your company will be more competitive, and your likelihood for promotion or career advancement will be improved. I would also encourage your suggestions on the substance of these suggestions, and would appreciate any other comments that you would like to pass on. Please e-mail me at Stonebraker1@comcast.net. * Pete Stonebraker is a Professor of Operations Management at Northeastern Illinois University. He received his Ph.D. in Operations Management from Arizona State University in 1981, and has managed various types of operations during a 22-year military career. Dr. Stonebraker teaches in the areas of statistics, operations management and operations research, and operations strategy. His courses in operations management and operations strategy have been recognized with national and international awards. In 1995, Pete was the recipient of a USIA grant to teach Production Management in Russia, and spent six months in the Siberian city of Ekaterinburg. He has authored seven books and over sixty academic and practitioner-focused articles, and consulted with both small and Fortune 500 companies in manufacturing, distribution and retailing. Pete has been a member of the Chicago Chapter since 1985 and was the Chapter VP for Membership for six years and a member of the Chapter Board of Directors for ten years. He was recently appointed as an external advisor to the APICS Body of Knowledge Council. He prepared the APICS Master Planning CPIM materials, has presented at national APICS conferences, and was recently the instructor for the pilot Strategic Management of Resources Course. He has taught all of the CPIM courses in various formats to in-house and two-day groups. His most recent book, Operations Strategy: Focusing Competitive Excellence, (with Keong Leong of The Ohio State University) was published by Allyn & Bacon and is the primary text for the Strategic Management of Resources course.