ch6

advertisement

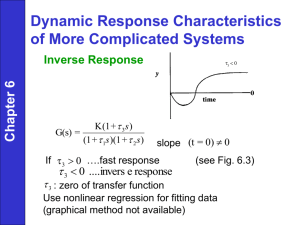

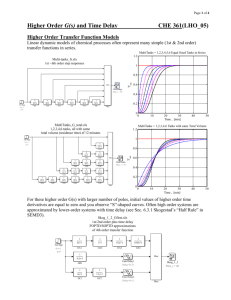

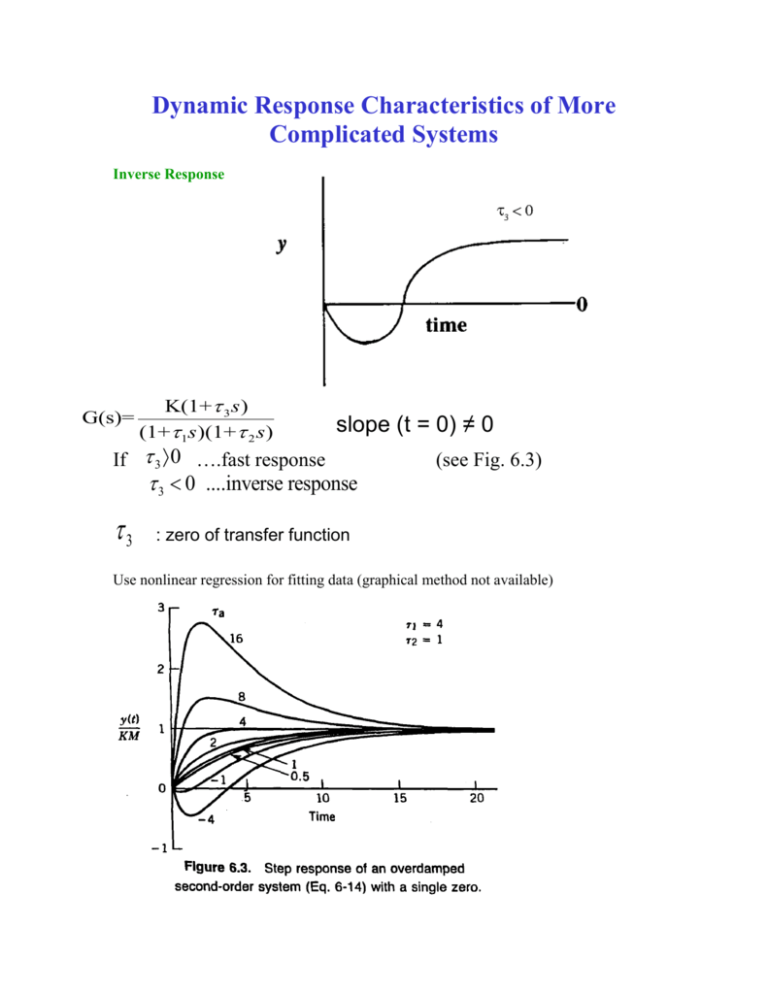

Dynamic Response Characteristics of More

Complicated Systems

Inverse Response

G(s)=

K(1+ 3 s )

(1+ 1s )(1+ 2 s )

slope (t = 0) ≠ 0

If 3 0 ….fast response

3 0 ....inverse response

3

(see Fig. 6.3)

: zero of transfer function

Use nonlinear regression for fitting data (graphical method not available)

For inverse response

G ( s)

K1 2 K 2 1

0

K1 K 2

K

s ( 1s 1)( 2 s 2 2 s 1)

4 poles (denominator is 4th order polynomial)

(6 21)

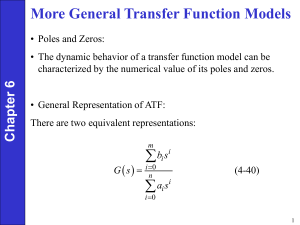

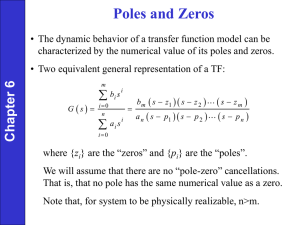

More General Transfer Function Models

•

•

Poles and Zeros:

The dynamic behavior of a transfer function model can be characterized by the

numerical value of its poles and zeros.

• General Representation of a TF:

There are two equivalent representations:

m

G s

bi si

i 0

n

(4-40)

ai si

i 0

G s

s zm

an s p1 s p2 s pn

bm s z1 s z2

(6-7)

where {zi} are the “zeros” and {pi} are the “poles”.

•

We will assume that there are no “pole-zero” cancellations. That is, that no pole

has the same numerical value as a zero.

•

Review: n m in order to have a physically realizable system.

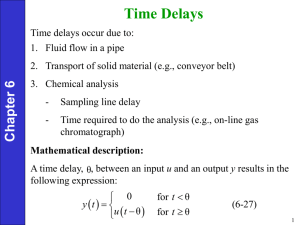

Time Delays

Time delays occur due to:

•

Fluid flow in a pipe

•

Transport of solid material (e.g., conveyor belt)

•

Chemical analysis

-

Sampling line delay

Time required to do the analysis (e.g., on-line gas chromatograph)

Mathematical description:

A time delay, θ, between an input u and an output y results in the following

expression:

0

y t

u t θ

for t θ

for t θ

(6-27)

G ( s) e s

Y (s)

U (s)

H1/Qi has numerator dynamics (see 6-72)

Approximation of Higher-Order Transfer Functions

In this section, we present a general approach for approximating high-order transfer

function models with lower-order models that have similar dynamic and steady-state

characteristics.

In Eq. 6-4 we showed that the transfer function for a time delay can be expressed as a

Taylor series expansion. For small values of s,

e θ 0 s 1 θ 0 s

•

(6-57)

An alternative first-order approximation consists of the transfer function,

e θ 0 s

1

eθ 0 s

1

1 θ0 s

(6-58)

where the time constant has a value of

• These expressions can be used to approximate the pole or zero term in a transfer

function.

Skogestad’s “half rule”

•

•

Skogestad (2002) has proposed an approximation method for higher-order models

that contain multiple time constants.

He approximates the largest neglected time constant in the following manner.

One half of its value is added to the existing time delay (if any) and the

other half is added to the smallest retained time constant.

Time constants that are smaller than the “largest neglected time constant”

are approximated as time delays using (6-58).

Example 6.4

Consider a transfer function:

G s

K 0.1s 1

5s 1 3s 1 0.5s 1

(6-59)

Derive an approximate first-order-plus-time-delay model,

G s

Keθs

τs 1

(6-60)

using two methods:

(a) The Taylor series expansions of Eqs. 6-57 and 6-58.

(b) Skogestad’s half rule

Compare the normalized responses of G(s) and the approximate models for a unit step

input.

Solution

•

The dominant time constant (5) is retained. Applying the approximations in

(6-57) and (6-58) gives:

0.1s 1 e0.1s

(6-61)

and

1

e3s

3s 1

1

e0.5 s

0.5s 1

(6-62)

Substitution into (6-59) gives the Taylor series approximation,

GTS s :

Ke 0.1s e 3s e 0.5 s Ke 3.6 s

GTS s

5s 1

5s 1

(6-63)

(b) To use Skogestad’s method, we note that the largest neglected time constant in

(6-59) has a value of three.

•

According to his “half rule”, half of this value is added to the next largest time

constant to generate a new time constant

τ 5 0.5(3) 6.5.

•

•

•

•

The other half provides a new time delay of 0.5(3) = 1.5.

The approximation of the RHP zero in (6-61) provides an additional time delay of

0.1.

Approximating the smallest time constant of 0.5 in (6-59) by (6-58) produces an

additional time delay of 0.5.

Thus the total time delay in (6-60) is,

θ 1.5 0.1 0.5 2.1

and G(s) can be approximated as:

GSk s

Ke 2.1s

6.5s 1

(6-64)

The normalized step responses for G(s) and the two approximate models are shown in

Fig. 6.10. Skogestad’s method provides better agreement with the actual response.

Figure 6.10 Comparison of

the actual and approximate

models for Example 6.4.

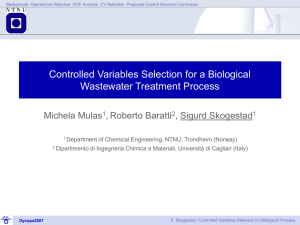

Multivariable Processes

many examples:

distillation columns,

FCC,

boilers,

etc.

Consider stirred tank with level controller

2 disturbances (Ti, wi)

2 control valves (A, B) manipulate ws, wo

2 measurements (T0, h)

controlled variables (T0, h)

change in w0 affects T0 and h

change in ws only affects T0

Three non-zero transfer functions

G11

T0 ( s )

Ws ( s )

G21

H (s)

Ws ( s )

G12

T0 ( s )

W0 ( s )

G22

H (s)

W0 ( s )

Transfer Function Matrix

T0 ( s) G11 G12 Ws ( s)

H ( s ) G

21 G22 W0 ( s)

From material and energy balances,

G11

K11

1s 1

G22

K 22

2s 1

G12

K12

( 1s 1)( 2 s 1)

Normal method, but interactions may present tuning problems.

In multivariable control, interactions are treated, but controller design is more

complicated.