chemical cleaning of auxiliary boiler

advertisement

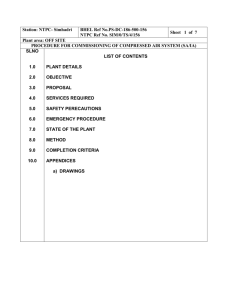

Station : NTPC - Simhadri BHEL Ref No. PS-DC-186-500-0015 NTPC Ref No. SIM/1/TS/1/011 Sheet 1 of 14 Plant Area : BOILER CHEMICAL CLEANING OF AUXILIARY BOILER SL.NO. LIST OF CONTENTS 1.0 PLANT DETAILS 2.0 OBJECTIVE 3.0 PROPOSAL 4.0 SERVICES REQUIRED 5.0 SAFETY PRECAUTIONS 6.0 EMERGENCY PROCEDURES 7.0 STATE OF THE PLANT 8.0 METHOD 9.0 COMPLETION CRITERIA 10.0 APPENDICES A. TECHNICAL SPECIFICATIONS B. SAFETY CLEARANCE CERTIFICATE C. MECHANICAL PLANT ITEM COMPLETION LIST & ELECTRICAL PLANT AND C&I PLANT ITEM COMPLETION LIST Station : NTPC - Simhadri BHEL Ref No. PS-DC-186-500-0015 NTPC Ref No. SIM/1/TS/1/011 Sheet 2 of 14 Plant Area : BOILER CHEMICAL CLEANING OF AUXILIARY BOILER 1.0 PLANT DETAILS STATUS The Steam generator is of natural circulation. Water tube design. arranged for pressurized firing. Basically it is a two drum vertical bent tube arrangement with water cooled furnace walls combined with the convective boiler bank surface. The complete steam generator is of the bottom supported design resting on concrete pedestals. The upper and lower drums are connected by the bank tubes. The steam drum is provided with efficient internals for steam separation. The unheated down comers are located in the rear half of boiler side wall ensures adequate circulation in the boiler. The boiler bank tubes are arranged in line for the best heat absorption. Minimum draft loss and easy tube inspection and cleaning. Required accessibility is provided at the side of the boiler bank convective surface. Adequate peep holes are provided to watch the flame. Feedwater is fed into the upper drum and circulation is maintained in the boiler bank through the downcomers. From the bottom drum water flows through the heat absotbing furnace tubes and back into the steam drum. After separation of moisture in the internals, the saturated steam flows through superheaters and to SH outlet steam collecting header from where the main steam is tapped off. The main fuels are Heavy Fuel Oil and Light Diesel Oil. The firing system consists of one no oil burner with register located in the front wall to carry MCR capacity with either of the fuels. The fuel oil is steam atomized: light oil is air atomized. High Energy Arc (HEA) ignitor is used for lighting up the burner. A flame scanning system is provided to monitor the flame condition in the furnace. Signatures NTPC BHEL Station : NTPC - Simhadri BHEL Ref No. PS-DC-186-500-0015 NTPC Ref No. SIM/1/TS/1/011 Sheet 3 of 14 Plant Area : BOILER CHEMICAL CLEANING OF AUXILIARY BOILER 1.0 PLANT DETAILS STATUS The HFO system consists of HFO day tank, 2 x 100% fuel oil pressurizing pumps with heaters, controls, piping, valves and fittings. The LDO system consists of LDO day tank with 1 x 100% LDO pressurizing pump with required controls piping. Valves and fittings. The boiler is equipped with a deaerator and feed pumps to supply deaerated feed water at 105 Deg. C to the boiler. Blow down system with blow down tank, HP and LP chemical dosing system comprising tanks, pumps, piping valves and fittings are also provided. The boiler is equipped with two Radial FD fans (2x60%) with electric motor drive. The boiler and auxilaries will be complete with the required accessories associated equipment, fittings and valves, integral piping systems etc. Complete air and flue gas ducting upto and including steel chimney will be provided along with the required expansion joints, damper and supporting steel work. Refractory and thermal insulation, outer and inner casing materials will be provided as required. Signatures NTPC BHEL Station : NTPC - Simhadri BHEL Ref No. PS-DC-186-500-0015 NTPC Ref No. SIM/1/TS/1/011 Sheet 4 of 14 Plant Area : BOILER CHEMICAL CLEANING OF AUXILIARY BOILER 2.0 OBJECTIVE 2.1 The objective of this commissioning schedule is to clean the internal surface of the steam generating portion and heating surface (Economiser) using specified chemicals. STATUS Signatures NTPC BHEL Station : NTPC - Simhadri BHEL Ref No. PS-DC-186-500-0015 NTPC Ref No. SIM/1/TS/1/011 Sheet 5 of 14 Plant Area : BOILER CHEMICAL CLEANING OF AUXILIARY BOILER 3.0 PROPOSAL STATUS The objectives are achieved by carrying out the following testing proposals. 3.1 By carrying out an effective boil-out, grease, oil and any protective coatings applied are removed from the interior pressure parts of the auxiliary boiler Signatures NTPC BHEL Station : NTPC - Simhadri BHEL Ref No. PS-DC-186-500-0015 NTPC Ref No. SIM/1/TS/1/011 Sheet 6 of 14 Plant Area : BOILER CHEMICAL CLEANING OF AUXILIARY BOILER 4.01 SERVICES REQUIRED STATUS All the required quantities of chemicals as given below should be made available prior to the commencement of the process. SPECIFICATION OF CHEMICALS & QUANTITY NAME OF CHEMICALS 1. Trisodium Phosphate (Na3PO4. 12H2O) 30 Kg (IS:573/1992) 2.Disodium Phosphate(Na2 HP O4.12 H2O) 15 Kg (IS:566/1991) 4.02 Supply of adequate DM water to be ensured 4.03 415 V Supply available 4.04 220 AC/Dc, 110V AC, Control Supply available (Which ever is applicable). 4.05 Instrument / Service Air Available 4.06 Flood Lights / Telephones / Walkie - Talkie are available 4.07 Ambulance / car for emergency / fire tender available 4.08 Drum level guage glass should be made available with lighting arrangement and tale-tale switch cum light arrangement 4.09 Sufficient quantity of Raw/Fire water to be ensured for the neutralisation of the alkali boil out effluent in line with A.P. pollution control Board Norms Signatures NTPC BHEL Station : NTPC - Simhadri BHEL Ref No. PS-DC-186-500-0015 NTPC Ref No. SIM/1/TS/1/011 Sheet 7 of 14 Plant Area : BOILER CHEMICAL CLEANING OF AUXILIARY BOILER 5.0 SAFETY PRECAUTIONS STATUS 5.1 SAFETY EQUIPMENTS : ENSURE THE AVAILABILITY OF 1. GUM BOOTS (Various Sizes) 6 Pairs 2. Rubber Gloves 6 Pairs 3. Rubber or Polythne Aprons 6 Nos. 4. Helmets 12 Nos. 5. Safety Goggles Plain Glass 6 Nos. 6. Face Mask (Transparent, Plastic) 4 Nos. 7. First aid box (containing dilute ammonium hydroxide, 50% sodium bicarbonate solution, eye loction, bandages, tincture of idodine, cotton, burnol etc. 8. Safety shower. EMERGENCY PROVISIONS 5.2 Flushing and washing water supplies 5.2.1 Ample supplies of flushing and washing water supplies shall be provided at all possible points of discharge, spillage or escape of chemicals. 5.2.2 Adequate provisions shall be made for emergency treatment of the eyes, comprising eye wash bottles, located conveniently to places where charging of chemicals are planned. 5.2.3 Telephone facilities shall be provided within a reasonable distance of the place where chemicals are being used Signatures NTPC BHEL Station : NTPC - Simhadri BHEL Ref No. PS-DC-186-500-0015 NTPC Ref No. SIM/1/TS/1/011 Sheet 8 of 14 Plant Area : BOILER CHEMICAL CLEANING OF AUXILIARY BOILER 6.0 EMERGENCY PROCEDURES 6.1 The testing team should be aware of the operating procedures of fire extinguishers to be used for quenching minor or major fires 6.2 The testing team should be aware of the procedure to be followed in case of accident involving personnel injury. STATUS Signatures NTPC BHEL Station : NTPC - Simhadri BHEL Ref No. PS-DC-186-500-0015 NTPC Ref No. SIM/1/TS/1/011 Sheet 9 of 14 Plant Area : BOILER CHEMICAL CLEANING OF AUXILIARY BOILER 7.0 STATE OF THE PLANT 7.1 Auxilary Boiler erection must have been completed as per approved scheme in respect of all ie. machanical, electrical and C&I area. 7.2 Hydraulic test of boiler should have been completed to the required parameter. Pl. specify the HYD. Test Pressure. 7.3 Preboiler system circuits should be available for operation. 7.4 For alkali boilout, minimum essential instruments required for boiler light up are made available 7.5 Boiler should be ready for regular operation as per Q & M instructions. 7.6 Sampling system should be ready. 7.7 Ensure free access to all equipment. 7.8 Ensure the readiness of fire fighting system as envisaged in the design. 7.9 Ensure the availability of fire tender near the boiler area. STATUS Signatures NTPC BHEL Station : NTPC - Simhadri BHEL Ref No. PS-DC-186-500-0015 NTPC Ref No. SIM/1/TS/1/011 Sheet 10 of 14 Plant Area : BOILER CHEMICAL CLEANING OF AUXILIARY BOILER 8.0 METHOD STATUS ALKALI BOIL OUT 8.1 The boiler (steam generating surfaces and economiser) is filled with an alkaline solution containing 500 ppm of disodium phosphate dodeca hydrate, and 1000 ppm of Tri sodium phosphate do deca hydrate and then fired to raise the pressure to 10 kg/ cm2, following the specified operational procedures. 8.2 Procedure Prepare the boil out chemical solution in demineralised water in a chemical mixing tank. The solution is formulated by dissolving the following proportionate quantities of chemicals, depending on the volume of the system to be cleaned. 1. 0.05% Na2 HPO4 2. 0.1 % Na3 PO4 12 H2O 12 H2O 8.3 Hold the solution prepared as above in the tank and homogenise the same by proper mixing the solution. 8.4 Start filling the Aux. boiler with demineralised water, until the water is seen little above the bottom of the upper drum. 8.5 Pour the chemical solution with the drum through the manhole by several increments. 8.6 Close the man hole cover and fill up with DM water upto normal operation level. Signatures NTPC Station : NTPC - Simhadri BHEL BHEL Ref No. PS-DC-186-500-0015 Sheet 11 of 14 NTPC Ref No. SIM/1/TS/1/011 Plant Area : BOILER CHEMICAL CLEANING OF AUXILIARY BOILER STATUS 8.7 Light up the boiler as per O & M instructions and gradually raise the pressure to 10 Kg/CM2 . Hold the pressure for four hours. Prescribe blow down every 2 Hrs. Once, after killing the fire; Duration of the blow down shall be for one minute Ensure that the drum level does not go out of gauge glass vision. 8.8 Repeat the operation of raising the pressure to 10 kg/cm2 and prescribing blow down every 2 hours (Total 4 Blow downs) after killing fire. 8.9 The boil out is declared completed when minimum 4 blow downs are completed. 8.10 Drain the boiler, when it is cooled, as per O & M instructions. Once the draining is completed, fill the boiler with demineralised water, through boiler fill pump. Back flush the superheaters with DM water containing 200 ppm hydrazine and pH 10.0 with NH3 till it overflows into the drum. Drain the boiler to the waste disposal system. Inspect the upper drum and manually clean, if any loose muck and sludge are present. 8.10 The effluent of alkali boil out shall be neutralised and disposed in line with A.P. pollution control Board norms. PH of the solution is lowered to less than 9.0 by sufficient dilution with raw / fire water. Signatures NTPC BHEL Station : NTPC - Simhadri BHEL Ref No. PS-DC-186-500-0015 NTPC Ref No. SIM/1/TS/1/011 Sheet 12 of 14 Plant Area : BOILER CHEMICAL CLEANING OF AUXILIARY BOILER 9.0 COMPLETION CRITERIA STATUS The completion criteria is time based boil out at 10 kg persg.cm for 10 hrs with intermittent blowdown at once in 2 hours with each blowdown for 1 minute Duration. Drum is inspected and all the loose muck and other dirts are cleaned ( Upper Drum ) Signatures NTPC BHEL Station : NTPC - Simhadri BHEL Ref No. PS-DC-186-500-0015 NTPC Ref No. SIM/1/TS/1/011 Sheet 13 of 14 Plant Area : BOILER CHEMICAL CLEANING OF AUXILIARY BOILER 10.0 APPENDICES a. TECHNICAL SPECIFICATION 1. Boiler : Natural circulation water tube design, bottom supported 2. Boiler Drum Drum ID Shell Length Material 3. 2897 mm 8258 mm 4242 mm Super Heater Tube O.D No.of Assemblies Heating Surface 5. 51.0 mm 15 13.75m2 Predicted Performance 1. 2. 3. 1. 2. 3. 5. 762(W) 8610 Furnace Width Depth Height 4. 1219(S) 8810 SA515 Gr 70 Flow SH Steam Combustion Air Flue Gas Tonnnes 55.0 61.0 65.0 Pressure Drum Operating Drum Design Steam Pressure at SHO outlet Kg/Cm2 (g) 21.4 25.0 18.0 Temperature 1. At SHO 2150 C Signatures NTPC BHEL Station : NTPC - Simhadri BHEL Ref No. PS-DC-186-500-0015 NTPC Ref No. SIM/1/TS/1/011 Sheet 14 of 14 Plant Area : BOILER CHEMICAL CLEANING OF AUXILIARY BOILER STATUS 6. Sl. No SAFETY VALVES LOCATION VALVE SET PRESSURE KSC VALVE TAG NO OPEN CLOSE % BLOW DOWN 1) DRUM SV1 25.0 24.0 4.0 2) DRUM SV2 25.8 24.7 4.3 3) SH SV3 20.5 19.6 4.4 REMARK% NOTE: Percentage blow down to be within 3% -5% of value lifting pressure 7. Water Valume in m3 1.Upper drum upto normal water level Upper drum flooded 2.Lower drum b. 3.9 11.3 4.2 3.water walls including Boiler bank tubes 18.7 4.SH system upto M.S.Stop valve 2.0 SAFETY CLEARANCE CERTIFICATE List of signatories required before running the system will be mutually decided at site. c. MECHANICAL /ELECTRICAL/C & I PLANT ITEM COMPLETION LIST The plant item completion list for the above areas will be mutually prepared at site by BHEL and NTPC. Signatures NTPC BHEL CHEMICAL CLEANING OF AUXILIARY BOILER PROGRESS REPORT : SG 16 JULY 2001