advanced metals

advertisement

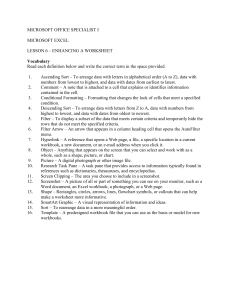

ADVANCED METALS / MACHINE OPERATIONS SYLLABUS Advanced Metals is designed to expose students to the basic operations, skills, and procedures used in production metalworking. The course content is designed to allow student exploration through lectures, demonstrations, and hands-on labs. Course content: - Introduction of class / explanation of content * Explanation of the course structure (hands-on approach to learning) * Overview of course projects and fees * Rules and Procedures permission slips - Careers in Metal Working * What careers involve Metalworking * Salaries, Schooling, Degrees, Conditions, Nature of Work - Unit 3 Safety *Workbook Unit 3 - Unit 2 Introduction to Metals * The Importance of Metals * Properties of Metals * Classification of Metals * Workbook Unit 2 - Unit 6 Kinds of Steel *Plain Carbon / Alloy Steels * % of Carbon Ranges * Workbook Unit 6 - Unit 8 Metal Designation and Identification * Steel Numbering System * Spark Test (DEMONSTRATION) * Workbook Unit 8 - Unit 49 Holding Work Pieces for Machining * Holding Devices and Accessories * Fixtures * Drill Jigs * Workbook Unit 49 - Unit 50 Lubricants and Cutting Fluids * Oils * Grease * Other Lubricants * Methods of Application *Cutting Fluids *Cutting Fluid Selection *Methods of Applying Cutting Fluids *Workbook Unit 50 - Unit 51 Stock Cutoff Machines * Hacksaws * Band Saws * Cold Saws * Abrasive Cutoff Saws * Stock Cutoff Operations * Workbook Unit 51 - Unit 52 Band Sawing and Machining *Vertical Band Saws * Cutting Speeds * Blade Tension * Blade Selection * Workbook Unit 52 - Unit 53 Drilling Machines * Drill Press * Multiple Spindle Drill Press * Radial Drill Press * Turret Press * Parts * Drill Press Size * Workbook Unit 53 - Unit 54 Drills, Sleeves, Sockets, and Chucks * “Drill Bits” * Sleeves * Sockets * Chucks * Workbook Unit 54 - Unit 55 Drilling * Cutting Speeds * Applications * Workbook Unit 55 - Unit 56 Other Drill Press Operations * Reaming * Countersinking * Counterboring * Spot Facing * Tapping * Boring * Workbook Unit 56 - Unit 58 The Metalworking Lathe * Lathe Types * Lathe Sizes * Lathe Parts * Workbook Unit 58 - Unit 59 Methods of Holding Workpieces in a Lathe * Noses * Chucks * Holding Between Centers * Workbook Unit 59 - Unit 60 Lathe Cutting Tools, Toolholders, Cutting Speeds, and Feed Selection * Cutting Tools Materials * Tool Holders * Cutting Speeds * Workbook Unit 60 - Unit 63 Straight Turning, Facing, and Boring * Straight Turning * Facing * Boring * Workbook Unit 63 - Unit 62 Drilling, Reaming, Countersinking, and Counterboring in a Lathe * Parts * Procedures * Workbook Unit 62 - Unit 64 Taper Turning * Compound Rest * Tailstock * Taper Attachment * Workbook Unit 64 - Unit 68 Milling Machines * Types of Milling Machines * Parts and Adjustments * Feed and Direction * Safety * Workbook Unit 68 - Unit 69 Workpiece Holding Devices and Accessories * Vises * Heads * Arbors, Collets, Adapters, and Holders * Workbook Unit 69 - Unit 70 Milling Cutters * Cutter Types * Cutter Materials * Fluids * Workbook Unit 70 - Unit 71 Cutting Speeds and Feeds for Milling * Speed Calculations * Feed Rate * Workbook Unit 71 - Unit 72-75 Milling Procedures * Workbook Unit 72-75 Lab Rotations SHEET METAL - Units 12, 13, 17, 24, 29, 30, & 31 SMAW WELDING - See instructor for Units MIG WELDING - See instructor for Units LATHE TURNING – Units 58,59,60,61,62,63,66 PLASMA TORCH - See Instructor for Units BAND SAW – Unit 52 MILLING – Units 68, 69, 70, 71, 75 CNC / POWDER COATING – Units 90, 91, 92 OXYGEN / ACETYLENE WELDING – See instructor for Units THREADING – Units 20 and 21 METAL TREATING – Units 38, 39, 40, and 41 PRODUCTION RUNS – See Instructor for Units EVALUATION OF STUDENT ACHIEVEMENT: Evaluation will be done by grading homework assignments, tests, and quizzes. Evaluation will also be done through the grading of projects. Each project will follow a strict grading rubric. CURRICULUM The first day of each school week will be devoted to a series of ten Caterpillar instructional units. The second day will be followed with a quiz over the assigned unit and then lab work will resume. These units were created to instruct students on industrial processes that relate with the instructional lab units. Each student is responsible for completing the assignments. If a student is absent on any day it is their responsibility to obtain the material that they missed. OPEN LAB TIME The 1201 lab will be open before and after school. Contact your instructor for open lab dates and times. FEES Each student will be charged a $25.00 lab fee that will pay for shop materials such as welding rods, welding gases, tooling apparatus, course project metal, and finishing supplies. This fee DOES NOT cover the amount of money needed for items such as locks, welding gloves, helmets, and safety glasses. Students will be responsible for obtaining a pair of safety glasses that are Z 87 approved. Safety glasses will be sold for $4.00 by the Technology Dept. If a student would like to buy welding gloves and / or helmets they can also be purchased through the Technology Dept. Welding gloves are $6.00 and welding helmets are $35.00. Locks can be purchased through the NCWHS main office. GRADING SCALE: 100 – 90 A 89 – 80 B 79 – 70 C 69 –60 D 59 or lower F COURSE SUPPLIES LIST: 1. Tape Measure (8’ – 12’) 2. Safety Glasses (Can be purchased in class for $4.00) 3. Spiral notebook and folder 4. NCWHS “Master” combination lock (must be purchased in the main office for $5.00) INSTRUCTOR: John Mackinson Office Number: 1201A E-mail: MACKINSJ@unit5.org