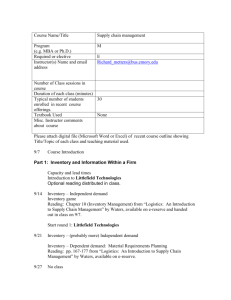

operations management, opmt 405

advertisement

OPERATIONS MANAGEMENT, OPMT 405 Instructor: Phone #: Fax #: E-mail: Office: Office hrs: TA: Professor George L. Vairaktarakis (216) 368-5215 (216) 368-6250 gxv5@po.cwru.edu Room 323 Peter B. Lewis by Appointment TBD COURSE DESCRIPTION Operations managers, ranging from supervisors to vice presidents, are concerned with the production of goods and services. More specifically, they are responsible for designing, running, controlling and improving the systems that accomplish production. This course is a broad-spectrum course with emphasis on techniques and information that are helpful to the practice of management in general and at any level. We will discuss commonly occurring application problems such as capacity planning, production scheduling, line balancing, inventory control, quality management, just-in-time concepts, etc. The field of operations management was originally concerned with manufacturing systems. But many of the same ideas apply, and the same trade-offs are present, in service organizations like health care, insurance, hotelmanagement, airlines and government related operations. Several manufacturing and non-manufacturing environments will be discussed explicitly, and the emphasis will be on the fundamentals of the operations function in an organization. Also we will explore the interface of operations management with other functional areas such as marketing, finance, accounting, etc. This course is not oriented toward specialists in operations management. Its goal is to introduce you to the environments and help you appreciate the problems that operations managers are confronted with. Then, we will typically discuss some system specifics and emphasize the principles and issues that play key role in their management. Course Materials The required texts are: - Course pack (CWRU Notes) Eliyahu M. Goldratt, The Goal, latest edition, North River Press, Inc., NY 10520. If you would like an additional reference, you might consider: Norman Gaither, Production and Operations Management, Latest edition, Duxbury press, Belmont, California 94002. COURSE REQUIRMENTS In this course every student needs to have: Working knowledge of EXCEL or comparable program Working knowledge of the STORM package on quantitative modeling 1 The course involves a combination of lectures and class discussions of readings and cases that are contained in the course pack. As described below, the workload consists of class participation, individual assignments, and a book review. The course grade will be based on the weights shown in parenthesis. Class Participation (10%) Students are expected to come to class prepared and actively participate in class discussions. Useful criteria for measuring effective class participation include: 1. Is the student absent too many times? Is the participant a good listener? 2. Are the points that are made relevant to the discussion? Are they linked to the comments of others? 3. Do the comments show evidence of analysis of the case? 4. Is there a willingness to participate? 5. Is there a willingness to test new ideas, or are all comments “safe” (e.g., repetition of case facts without analysis and conclusions)? 6. Do the comments clarify or build upon the important aspects of earlier comments and lead to a clearer statement of the concepts being covered and the problems being addressed? Skill Building Exercises (15%) There will be several skill building exercises (SBE) assigned during the course. These assignments focus more on applying the quantitative methods developed in class rather than developing qualitative insights. SBE’s are individual assignments. You are encouraged to work with other students in the class on the concepts presented in class but not on the SBE’s. Strikingly similar solutions will be given feedback, be left ungraded and filed for further consideration. Please turn in your SBE, properly stapled if more than 2 pages, at the beginning of the corresponding class session. Credit on homework will be proportional to both effort and correctness. Please note that late submission of homework is not acceptable. Critique of the Goal (15%) What is The Goal? The book claims to be many things. It claims to be about science and education, about progress, about global principles of manufacturing, and some of you might say that it is about a love story. For me the book is: (a) a fascinating description of an operations process, and for those of you without an operations background, an excellent opportunity to get an introduction to manufacturing environments, (b) an excellent example of how operations should be viewed: as a business function which can be understood with the use of a business language and not with the use of obscure technical terminology, and (c) a powerful demonstration that the most important, and in most cases only, prerequisite for becoming an operations manager is common sense and intellectual attraction to environments that exhibit complexity and variability. I recommend that you treat The Goal as a leisure activity and pace it over a few days. The danger is that some of you might find it such an irresistible reading that you may want to finish it overnight. After you read the book, answer the following questions. 1. 2. 3. 4. Provide the definitions of throughput, inventory and operational expense given in The Goal. How do they compare with the traditional definitions? Do you find them useful, and why? Provide the definition of a bottleneck machine. Develop your own simple example to demonstrate it to me. What are the production scheduling principles discussed in The Goal? Provide an explanation of the pitfalls, as discussed in The Goal, of using cost accounting data for manufacturing decision making. 2 The above is an individual assignment. It should not take more than two double spaced pages to answer the 4 questions. Littlefield Technologies Reports (10%) Littlefield Technologies is an online factory simulator. In a typical setting, students are divided into teams and compete against each other over several days. Student teams attempt to maximize their cash position by buying and selling capacity, adjusting lead time quotes, changing lot sizes and inventory ordering parameters, and selecting scheduling rules. Littlefield Technologies is used by more than two dozen business and industrial engineering programs to reinforce and motivate course material on queueing, capacity and utilization, inventory control and lead time management. The price per student is $15 per student per academic term for not-for-profit institutions. That entitles the institution to up to two simulations during the academic term. Each student needs to submit a check payable to “Responsive Learning Technologies” by Feb. 20, 2006 which will be sent by the instructor to Responsive Learning Technologies representatives. Information on how to register and play the game will be given by the instructor during the course. Further information and a demo of the game can be accessed via http://littlefield.responsive.net/littlefield/littlefieldHome.html. Guidelines for the group report each will be posted on Blackboard during the semester. Each report should be in the form of an executive summary. The key point to remember in writing the executive summary is to focus on important data, conclusions, and recommendations. An executive summary should be a managerial report that recommends a course of action assuming the reader is familiar with the problem. The reports should be no more than 3 pages plus appendices (computer output, graphs, charts, etc.). Your qualitative findings must be backed-up by quantitative findings when necessary. Midterm Exam (25%) The midterm exam will take place during the midterm week. The exam will include all the material covered in the course prior to the exam date. Final Exam (25%) The final exam will take place during finals week. This exam will include all the topics covered in class following the midterm exam. Grading: A curve will be used to determine each student’s final course grade. The curve will be determined based on the performance of the rest of the class. Attendance policy: I understand that other demands may require to miss a class, but with 8 or so class meetings, you should not be absent more than 1 time during the semester. In the event that you have to miss a class you should submit in advance any homework that has been assigned. Also, students should take the necessary steps to recover the missed lecture and assignments. Academic Integrity: All students in this course are expected to adhere to university standards of academic integrity. Cheating, plagiarism, and other forms of academic dishonesty will not be tolerated in the course. This includes, but is not limited to, consulting with another person during an exam, turning in written work that was prepared by someone other than you, and making minor modifications to the work of someone else and turning it in as your own. Ignorance will not be permitted as an excuse. If you are not sure whether something you plan to submit would be considered either cheating or plagiarism, it is your responsibility to ask for clarification. When your name appears on a group product for a class, you are responsible for the integrity of the work, even if you did not personally write the offending material. Either ask me about it or consult credible sources of information on the subject. Two useful internet sites are http://www.indiana.edu/~wts/pamphlets/plagiarism.shtml and http://www.unc.edu/depts/wcweb/handouts/apa.html. Please remember that you have agreed to Standards Regarding Academic Integrity (a copy of which can be found at http://weatherhead.case.edu/pdpao/policy/policyhome.html) which outlines your responsibility in greater detail. 3 ABRIDGED OUTLINE SESSION TOPIC MODULE 1 1. Jan 17 Operations Process Analysis Overview of syllabus, Introduction to OM, “Littlefield Technologies” (F2F) Measuring Capacity: Process Fundamentals Measuring Capacity: Kristen’s Cookie Company (VDO) Bottleneck Analysis and Congestion: Nat’l Cranberry Cooperative Assignment on Goal is due in-class on Jan 31. Bottleneck Analysis and Congestion: Nat’l Cranberry Cooperative continued (F2F) Skill Building Exercise 1 is due in class on Feb 14. 2. Jan 24 3. Jan 31 MODULE 2 4. Feb 7 5. Feb 14 Face-to-face (F2F) and Video (VDO) lectures 8. Mar 7 Managing Capacity Aligning Process Design & Business Objectives: McDonalds, Burger King (VDO) Capacity Planning for Service Processes (F2F) Skill Building Exercise 2 is due on Feb 28 in-class Managing a Capacity Constrained Service System: NYPD (VDO) The Economic Order Quantity (EOQ) model (F2F) Introduction to “Littlefield Technologies - Part 1” Littlefield Simulation group report due on Mar 14 in-class Review Session (VDO) 9. Mar 14 Midterm (open books/notes, F2F) MODULE 3 10. Mar 21 Supply Chain Management Dealing with Uncertainty (VDO) 6. Feb 21 7. Feb 28 Centralized versus Decentralized Inventories: Acme Widget 11. Mar 28 Implementing a Production and Inventory Policy: Blanchard Importing & Distributing (F2F) Skill Building Exercise 3 is due on Apr 11 in-class 12. Apr 4 MRP and Kanban (VDO) 13. Apr 11 Introduction to “Littlefield Technologies - Part 2” (F2F) Read: “Managing Customer Responsiveness at Littlefield Technologies” Littlefield Simulation group report due on Apr 25 in-class The Beer Game MODULE 4 Management of Quality 14. Apr 18 Introduction to Quality/The Tools of Quality (VDO) 15. Apr 25 Using Data to Diagnose a Quality Problem: Plastron Division (F2F) 16. May 2 FINAL EXAM (open books/notes, F2F) 4 COURSE READINGS and QUESTIONS MODULE 1: OPERATIONS PROCESS ANALYSIS SESSION 1: Overview of Syllabus, Introduction to Operations Management Readings: Syllabus, Process Fundamentals SESSION 2: Measuring Capacity Reading: Kristen’s Cookie Company Kristen’s Cookie Company 1. How quickly can Kristen fill an order for 1 dozen cookies? 2 dozen? 3 dozen? 2. What is the maximum rate at which Kristen can produce cookies if she makes batches of 1 dozen, 2 dozen, 3 dozen? What assumptions do you have to make? SESSION 3: Bottleneck Analysis and Congestion Reading: National Cranberry Cooperative National Cranberry Cooperative 1. Draw the process flow diagram showing the major process steps, inventories and flows. Indicate the capacity at each of the process steps. 2. In Exhibit 2 of the case it is shown that, over the 20 days from 9/20/ to 10/9, an average of 16,400 barrels per day are delivered. Assume that on average each truck carries 75 barrels, and that trucks arrive uniformly over a 12 hour period. Also assume that during this period, the trucks carry 70% wet berries and 30% dry berries. (a) Which operation(s) are bottlenecks? Note that both dry and wet berries can be run through the system at the same time. (b) How much overtime is required? (c) Why are the truck waiting times so high? 3. What alternatives are there for improving the operation? How would you evaluate them? On what basis would you compare them? 4. What major sources of uncertainty may affect the performance of RP#1? MODULE 2: MANAGING CAPACITY SESSION 4: Aligning Process Design and Business Objectives Readings: McDonald’s Corporation Burger King Corporation McDonald’s/Burger King Corporation Discussion Questions 1. For each case, draw a process flow diagram that reflects the major components of the current operations. Keep the diagrams simple. How do the two diagrams reflect the differences in competitive strategies? 2. What performance characteristics are relevant for these two operations? What implicit or explicit standards, if any are used? How is each system managed so as to achieve these standards? SESSION 5: Capacity Planning for Service Processes Reading: lecture notes SESSION 6: Managing a Capacity Constrained Service System Reading: NYPD Patrol System NYPD Patrol System 1. Assume that you have 18 cars to allocate for this tour. How many should you assign to each precinct? What is your objective? Are there alternative objectives that might be considered? 5 2. 3. Assuming now that there is no “budget” of cars, how many cars should be assigned to each precinct to achieve “good’ performance? Why might the actual delays experienced by callers to 911 be different from those predicted by the model that you have used? SESSION 7: Introduction to “Littlefield Technologies - Part 1” Readings: Littlefield Technologies: Overview Capacity Management at Littlefield Technologies MODULE 3: SUPPLY CHAIN MANAGEMENT SESSION 10: Centralized versus Decentralized Inventories Reading: Acme Widget SESSION 11: Implementing a Production and Inventory Policy Reading: Blanchard Importing and Distributing Inc. Blanchard Importing and Distributing Inc. 1. What is wrong with the way that the EOQ and ROP quantities have been determined for each of the five items mentioned in the case? 2. Assuming that an EOQ/ROP system is an appropriate way to run this system, how would you correct the EOQ/ROP quantities for the five items? How do the corrected figures compare with the quantities calculated in 1969 and with production volumes scheduled for the June 1972 bottling run? 3. What are the advantages and/or disadvantages of the formal EOQ/ROP system and the actual system used for scheduling bottling runs at Blanchard? Which system do you prefer? What improvements can be made? 4. What should Hank Hatch recommend to his boss, Toby Tyler? SESSION 12: MRP and Kanban Reading: Note on MRP SESSION 13: Introduction to “Littlefield Technologies - Part 2” Readings: Managing Customer Responsiveness at Littlefield Technologies The Beer Game MODULE 4: MANAGEMENT of QUALITY SESSION 14: Introduction to Quality/The Tools of Quality Reading: none SESSION 15: Using Data to Diagnose a Problem Reading: Plastron Division 6