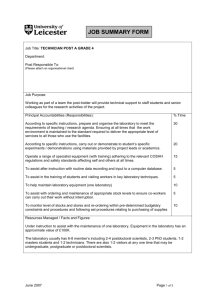

Technical officer

advertisement

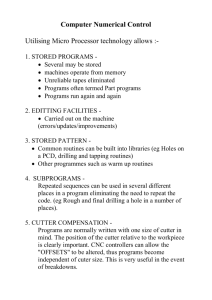

UTS POSITION DESCRIPTION UTS:ENGINEERING POSITION TITLE Technical Officer UNIT/FACULTY Engineering POSITION PURPOSE The Technical Officer is accountable for the provision of specialised Computerised Numerical Control (CNC) machining and manufacturing expertise for undergraduate and postgraduate laboratory classes and research projects in the laboratories of Mechanical and Mechatronics Engineering. DIMENSIONS The Technical Officer provides support for 9 laboratory areas for the Mechatronic and Intelligent Systems (MIS) group. There are approximately 400 students in the MIS field of practice. Each semester 36 laboratory classes are delivered for 11 undergraduate subjects and postgraduate electives as required. The Technical Officer will also provide technical support to capstone students and postgraduate research students as required. There have been up to 10 capstone students and at least 5 research students utilising the laboratories each semester. RELATIONSHIPS Supervision The Technical Officer is one of four staff members that report to the Manager, Manufacturing Processes and Research Laboratory. There are no positions that report to the Technical Officer. Collaboration and Communication Internally, the Technical Officer liaises with the Manager, Manufacturing Processes and Research Laboratory, academics and students to ensure the toolmaking needs of the laboratory are met. Externally, the Technical Officer communicates with suppliers to determine suitable stock and materials for maintenance purposes. MAJOR RESPONSIBILITIES The Technical Officer: Is responsible for delivering practical classes that demonstrate fundamental machining operations. This includes surface and cylindrical grinding, milling, turning and gear cutting. The students need to be able to shown the application of each operation in a production environment and the reasons for each operation. Directly supervises undergraduate and postgraduate students to assist with procedures and operations for CNC machining and metrology. The main priority is that the equipment is safely operated. The students must demonstrate process efficiencies, correct tool July 2006 1 paths, cutting speeds and feed rates, depending on the material, geometry, required tolerances and surface finishes. Completes required machining and toolmaking projects needed for practical classes and research and consulting projects in the laboratories. The machined products must meet the original specification, including required tolerances and surface finishes, within the agreed timeframes. Performs routine machine maintenance to ensure the practical classes and research projects are uninterrupted. This involves machine calibration, replacing or sharpening tool pieces, maintaining correct fluid levels and viscosities and keeping the machines clean and free of swarf. Assists in keeping the laboratories in a functional state. This requires reorganising equipment and materials, laboratory cleaning and housekeeping. Is accountable for ensuring that the Environment, Health and Safety (EHS) policies of the university are implemented and adhered to at all times. Knowledge of EHS procedures is essential for working in the laboratory environment. Ensuring appropriate certification of students is the most important safety consideration. Documentation of risk assessments, safe work method statements, material safety data sheets and operational procedures is also required. ENVIRONMENT AND POSITION CHALLENGES The Technical Officer must; Ensure toolmaking projects are completed in a timely manner, so as not to disrupt or delay student assessment. Maintain knowledge of current CNC machining and manufacturing technologies Adapt current technologies to technically diverse laboratory areas AUTHORITY TO ACT The Technical Officer works under general direction. The Technical Officer is guided by the Manager, Manufacturing Processes and Research Laboratory and relevant academic staff. Safety & Wellbeing responsibilities All staff must: Take reasonable care of, and cooperate with actions taken to protect, the health and safety of both themselves and others report all accidents, incidents and hazards to their supervisor as soon as is practicable Supervisors and managers of staff and facilities must do whatever is reasonably practical to ensure that both the workplace and the work itself are safe, in consultation with staff affected. July 2006 2 ORGANISATION CHART Please see attached. July 2006 3 APPROVALS Incumbent Supervisor (if required) Manager (minimum level Dean/Director) Name: Matthew Low Lothar Weber Title: Manager, Manufacturing Processes and Research Laboratory Technical Services and Assets Manager Signature: Date: July 2006 4