rotation2finalreport

advertisement

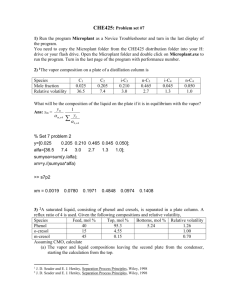

Brown Industries GGBL Building Ann Arbor, MI 48109-2136 DATE: November 11, 2002 TO: Richard Wagner, Plant Supervisor, Brown Industries FROM: Emma Wong, Team Leader, Brown Industries Mario Fabiilli, Staff Engineer, Brown Industries Jessica Garbern, Staff Engineer, Brown Industries SUBJECT: Final Report for the Methanol Recovery Optimization via Distillation: Rotation 2 REF: Distillation work plan (10/21/02) Rotation 1 final report (10/7/02) Fogler memo (9/3/02) Abstract To investigate the feasibility of recovering of 97 vol% methanol from Brown Industries waste streams (waste streams: 5-10 vol% methanol), we needed to characterize our packed bed distillation column, assess and expand the flooding correlation provided by Rotation 1, and develop a model to predict the column performance. We quantified the effects of feed flow rate and feed temperature on product (methanol distillate) concentration (xD) and mass transfer coefficient (KOG). We determined that as the feed rate increased, the x D increased while KOG decreased. However, we found no correlation between feed temperature and x D or KOG. We determined that there was no correlation between reflux ratio and flooding and found that the correlation from Rotation 1 is accurate. To develop our model, we assumed the constant molar overflow assumption is valid for this system because the latent heats of vaporization of methanol and water are comparable (water: 35210 kJ/mol; methanol: 40657 kJ/mol). Our Excel model predicts column performance by taking inputs of reflux ratio, reboiler power, feed weight fraction, feed temperature, and distillate weight fraction and determining the optimum flow rate at which to run the column to satisfy these conditions. To account for changes in K OG at different column conditions, a correlation relating the KOG to feed flow rate and reflux ratio was determined using Polymath (KOG = 2123.5·(feed flow rate)-0.933·(reflux ratio)-0.552). The model also predicts whether or not flooding will occur using the Rotation 1 flooding correlation. This model can be used to determine the appropriate operating conditions to purify the methanol waste stream. Finally, we evaluated the online, tray distillation column designed by the University of Tennessee. We conclude that the simulation is good and relatively easy to use; however we also recommend a few changes we feel would improve the usability of the column. 1 Introduction Manufacturing processes at Brown Industries currently produce aqueous waste streams containing 5-10 vol% methanol. If concentrated to at least 97 vol% methanol, these waste streams can potentially be sold to outside vendors for a profit. On September 3, 2002, Dr. Fogler requested that we investigate the feasibility of this methanol recovery process using the packed-bed distillation column in the Brown Industries Lab. To help us meet the objectives for Rotation 2, we used operational limits proposed by Rotation 1 on the pilot-scale methanolwater distillation column. Dr. Fogler also requested that we evaluate the online tray distillation column designed by the University of Tennessee-Chattanooga. We set the following objectives to meet these goals: Quantify the effect of feed flow rate and feed temperature on product concentration (x D) and mass transfer coefficient (KOG). (See Appendix A for variable definitions.) Assess the effect of changing reflux ratio on flooding. Evaluate the proposed flooding correlation from Rotation 1. Determine whether the constant molal overflow assumption or the enthalpy-concentration method is valid for this distillation column. Develop a model to predict column performance that incorporates the following relevant parameters: – Feed flow rate – Reflux ratio – Reboiler power – Changes in the mass transfer coefficient – Flooding Evaluate the online, tray distillation column designed by the University of Tennessee. This report details our completed work for Rotation 2. Theory and Data Analysis Distillation is used to separate components in liquid solution. The separation is based on the different boiling points of the components in the mixture. When the liquid mixture is heated, a vapor forms, and the distribution of the components in the liquid and vapor phases will be different because of the different boiling points. Vapor leaving the top of the column, called distillate, is condensed. Part of the distillate is returned to the column as reflux, which allows liquid to flow back down the column and creates the opportunity for mass transfer between phases. The remaining distillate is removed as product. A reboiler also vaporizes some of the falling liquid while the remaining liquid exits the column as bottoms. Feed Conditions Feed flow rate can affect mass transfer by causing either laminar or turbulent flow in the column. At lower flow rates, the flow is laminar, which limits contact between the liquid and 2 vapor phases, leading to relatively low mass transfer. However, at higher flow rates, the flow becomes turbulent, which improves mass transfer between phases. Feed temperature affects the quality of the feed stream, where quality is the ratio of the amount of heat needed to vaporize one mole of feed at the entering conditions to the molar latent heat of vaporization of the feed. For a saturated liquid feed, q=1, while for a saturated vapor feed, q=0. The quality of the feed affects the slope of the operating lines, as the enriching and stripping operating lines intersect on the q-line (see “Constant Molal Overflow – McCabe Thiele Method” for more details). To quantify the effect of feed flow rate and feed temperature on the product concentration and mass transfer coefficient, we constructed the following plots of our experimental data: Feed flow rate versus product concentration Feed flow rate versus mass transfer coefficient Feed temperature versus product concentration Feed temperature versus mass transfer coefficient See Appendix B for detailed calculations involving KOG. Flooding Flooding occurs when the gas flow rate in the column is so great that the downward flow of liquid is hindered. If the gas flow rate is great enough, the liquid may actually rise up the column and exit in the distillate. We chose to examine reflux ratio because this value affects flow rates within the column, and may have an effect on flooding. Rotation 1 has shown that at small reflux ratios (i.e. producing a minimal increase in liquid flow compared to the feed rate), increased reboiler power is necessary to cause flooding at lower flow rates compared to higher flow rates. This may be because at low flow rates for a given reboiler power, there is less liquid falling down the column; thus an increased gas flow rate is necessary to result in a large enough liquid buildup to cause flooding. There are several methods to develop a flooding correlation for a distillation column. We used an empirical correlation to predict flooding as a function of feed flow rate, similar to Rotation 1. See Appendix C additional flooding correlations and Appendix D for detailed flooding calculations. We plotted the reboiler power at which flooding occurred versus feed flow rate (see Results - Flooding). Above this line results in flooding, while below this line indicates normal (non-flooding) operation. Constant Molal Overflow (McCabe-Thiele Method)4 We compared our data to predictions made by the McCabe-Thiele method to determine whether or not this method accurately simulates this distillation column. This method provides a graphical means of modeling the operation of a distillation column and can also be used to determine distillate composition or feed flow rate for a given set of conditions. The McCabe Thiele method assumes the following: 3 Equal latent heats of vaporization for all components Negligible differences for the sensible heat Constant molal overflow in each section of the column Because the McCabe-Thiele method assumes constant molar overflow (Equation 1), this results in straight operating lines. Vn+1 + Ln-1 = Lv + Ln (1) With this assumption, the following equations for the enriching section operating line (Equation 2), stripping-section operating line (Equation 3), and q-line (Equation 4) can be derived, respectively4. y n1 x R xn D R 1 R 1 (2) y Lm Wx xm w Vm1 Vm1 (3) y x q x F q 1 q 1 (4) For a liquid feed, the slope of the q-line increases as feed temperature increases until it reaches saturation (vertical q-line). If additional heat is added beyond saturated liquid, the feed becomes a mixture of liquid and vapor and the slope of the q-line ranges from 1 to 0. The qline, enriching operating line, and stripping operating line all intersect at a single point. Enthalpy-Concentration Method4 The enthalpy-concentration method accounts for differences in latent heats for each component, heats of solution or mixing, differences in sensible heats of the components, and does not assume constant molal flow. This results in curved operating lines. We determined whether this method is necessary for this system by comparing the latent heats of vaporization of methanol and water. This method would only me necessary if the latent heats are significantly different. Equation 5 gives the enriching-section operating line and Equation 3 gives the stripping-section operating line. y n1 Ln Dx D xn Vn1 Vn1 (5) A trial and error solution must be used to simulate a column with this approach. This method is detailed in Appendix E4. 4 Distillation Model We adapted a model provided by Rotation 1 to predict the performance of this column. This model is both experimentally and theoretically derived, where theory was used to construct the McCabe-Thiele plot, and empirical data was used to calculate the mass transfer coefficient. A detailed description of this model is found in Appendix F. This model allows us to account for changes in the mass transfer coefficient due to changes in column conditions, as well as predict when flooding will occur. Equipment2 The distillation apparatus we used to perform pilot-scale separation processes is shown in Appendix G. The 30-inch tall packed-bed distillation column contains 1/4-inch Pro-Pack stainless steel random packing within a 3-inch inner-diameter glass pipe. The apparatus has two available feed tanks: a smaller tank for use during recycle-mode and a larger tank for use during production-mode. We used the column in production-mode to remove the possibility that the hot bottoms being returned to the recycle feed tank could change our results due to additional feed preheating. The preheater heats the feed, which then enters the column in the top, middle, or bottom feed port. The vapor exits the top of the column to be condensed then sent to a distillate receiver. The distillate is returned to the column as reflux, returned to the feed tank during recycle-mode, or collected in a distillate tank during production-mode. A bottoms waste stream is removed from the reboiler and is either returned to the feed tank during recycle-mode or held in a bottoms tank during production. Additionally, Appendix H contains a MSDS for methanol. Throughout the distillation column there are seventeen thermocouples to record temperatures and four volumetric turbine flow meters to record feed, reflux, distillate, and bottoms flows. All of these values are recorded on a computer through LabTech Control software. For additional equipment operation instructions, see equipment manual2. A gas chromatograph (GC) was used to analyze and determine the composition of various streams. Samples of approximately 1 ml were removed with a syringe from the feed tank or sample ports in the apparatus, transferred to a 1 ml Eppendorf tube, and quickly capped. Then, using an injection syringe, a 0.2 l sample was placed in sample port B of the GC. The SOP for operating the GC was followed2. Because the GC has a high degree of error, it was calibrated before each use with the standard samples. The online distillation column at the University of Tennessee – Chattanooga is a 12-tray column. The operators can change the feed pump setting, reflux percentage, and reboiler power. Four real time images of the column are present on the user interface. Additionally, real time temperature profiles are given for each of the trays, feed, distillate, and reflux. 5 Experimental Design There are five independent variables with the Brown Industries distillation column: Feed flow rate Feed temperature Feed concentration Reboiler power Reflux ratio Dependent variables consist of temperatures and compositions of the distillate and bottoms streams, as well as the properties calculated from these values, including the mass transfer coefficient. Table 1 highlights the runs that we completed in order to determine the effects of feed flow rate and feed temperature on product concentration and hence the mass transfer coefficient. Table 1 – Experimental Runs Run 1 2 3 4 5 6 7 8 9 Feed Flow Rate (mL/min) 131 326 530 146 330 533 150 350 550 Feed Temperature (C) 25.0 23.6 24.2 35.0 35.0 35.0 45.0 45.0 48.7 Colored blocks indicate sets of runs, where the colored variables were varied while the others were held constant. The maximum feed rate and temperature were chosen based on maximum values reported by Rotation 1. During these runs, the feed concentration, feed location, reboiler power, and reflux ratio were set at 5.5 0.9 vol%, middle, 50% and 4.7, respectively. To continue the flooding study initiated by Rotation 1, we varied feed flow rate and reflux ratio according to the runs outlined in Table 2. For each run, the reboiler power was adjusted until flooding was observed, according to the methodology of Rotation 1. Table 2 –Runs to Determine Flooding Conditions Run 10 11 12 13 Feed Flow Rate (mL/min) 67 152 350 597 Reflux Ratio 36.7 59.4 38.8 48.6 6 Since Rotation 1 conducted runs at a reflux ratio of 6.7, we decided to operate at higher reflux ratios. We predicted that this variable would most affect the gas flow rate inside the column, and hence cause flooding. The feed temperature, concentration, and location were set to 56.5 12.1C, 5.5 0.9 vol%, and middle, respectively. Though there appears to be large variations in the feed temperature and reflux ratio between runs (due to difficulty maintaining steady state), we found that these fluctuations were insignificant and had no effect on determining a correlation for flooding or confirming the data found by Rotation 1. Further details can be found in the results and discussion sections. The online distillation column at the University of Tennessee can test three independent variables: feed pump setting, percent reflux, and reboiler power. Table 3 outlines the runs we completed while evaluating this column. We chose to examine the effect of feed pump setting on the methanol distillate composition. Distillate composition was determined by using the temperature of the top tray of the column and assuming that the vapor is at the saturation point on each tray. Due to equipment difficulties, we were unable to complete additional runs we had planned to examine the effects of reflux and reboiler power on distillate composition. Table 3 –Runs completed with UTC simulator Run 14 15 16 17 Reflux (%) 80 80 80 80 Reboiler Power (W) 2000 2000 2000 4000 Feed Pump 1 3 5 3 Results We performed runs using the experimental procedures described above to obtain the following results. Effect of Feed Flow Rate on Product Concentration and Mass Transfer Coefficient Figures 1 and 2 respectively illustrate the dependence of methanol distillate (product) concentration and the mass transfer coefficient on feed rate for feed temperatures of 25C, 35C, and 45C. Feed concentration, feed location, reboiler power, and reflux ratio were 5.5 0.9 vol%, middle, 50% and 4.7, respectively. Linear fits relating product concentration and the mass transfer coefficient to feed rate are displayed in Equations 6 - 11. 7 Product Concentration (vol% MeOH) Figure 1 – Product Concentration vs. Feed Rate 100 90 80 70 60 50 40 30 20 10 0 100 25C 45C 35C Linear (35C) Linear (45C) Linear (25C) 200 300 400 500 600 Feed Rate (mL/min) 25C: (vol%) = 0.0013 · F + 0.1378 with R2 = 0.98 35C: (vol%) = 0.0012 · F + 0.1214 with R2 = 0.99 45C: (vol%) = 0.0010 · F + 0.2236 with R2 = 0.95 (6) (7) (8) Figure 2 – Kog vs. Feed Rate 25C 12.00 45C KOG (mol/cm) 10.00 35C Linear (35C) 8.00 Linear (25C) Linear (45C) 6.00 4.00 2.00 0.00 100 200 300 400 500 600 Feed Rate(mL/min) 25C: Kog = -0.0186 · F + 10.758 with R2 = 0.99 35C: Kog = -0.0238 · F + 13.918 with R2 = 0.95 45C: Kog = -0.0147 · F + 9.4990 with R2 = 0.99 (9) (10) (11) 8 Effect of Feed Temperature on Product Concentration and Mass Transfer Coefficient Figures 3 and 4 respectively show product concentration and the mass transfer coefficient as a function of feed temperature, where Equations 12 -17 show the correlations obtained for feed flow rates of 150, 350, and 550 mL/min, respectively. Figure 3 – Product Concentration vs. Feed Temperature 100 Product Concentration (vol% MeOH) 90 80 70 150 60 350 50 550 40 Linear (150) 30 Linear (350) 20 Linear (550) 10 0 0 10 20 30 40 50 Feed Temperature(°C) 150 mL/min: (vol%) = 0.3211 · TF + 23.654 with R2 = 0.46 350 mL/min: (vol%) = -0.0457 · TF + 54.317 with R2 = 0.07 (13) 550 mL/min: (vol%) = -0.2729 · TF + 91.995 with R2 = 0.75 (14) (12) Figure 4 – Kog vs. Feed Temperature 9 12.00 KOG (mol/cm) 10.00 150 350 550 Linear (550) Linear (350) Linear (150) 8.00 6.00 4.00 2.00 0.00 0 10 20 30 40 50 Feed Temperature(C) 150 mL/min: Kog = 0.1238 · TF + 4.5584 with R2 = 0.42 350 mL/min: Kog = -2·10-5 · TF + 4.53 with R2 = 6·10-7 550 mL/min: Kog = -0.0144 · TF + 0.8247 with R2 = 0.49 (15) (16) (17) Flooding Figure 5 highlights flooding conditions that were obtained by Rotation 1 (reflux ratio of 6.7) and Rotation 2 (average reflux ratio of 46). Conditions at and above these points will result in column flooding. Flooding correlations at both reflux ratios relating feed flow rate and reboiler power are given in Equations 18 and 19, respectively. Appendix I contains additional graphs relating vapor flow rate to reboiler power and feed rate. Figure 5 – Flooding Conditions 10 100 Reflux ratio = 6.7 Reflux ratio = 46 Reboiler power (%) 95 90 85 80 75 70 0 200 400 600 800 Feed rate (mL/min) Rotation 1 (Reflux ratio = 6.7): Reboiler power = -0.0483·(feed flow rate) + 101.43, with R2 = 0.9956 (18) Rotation 2 (Reflux ratio = 46): Reboiler power = -0.0499·(feed flow rate) + 102.31, with R2 = 0.9948 (19) University of Tennessee Distillation Column: Feed Pump Setting versus Product Concentration The data that was collected from the distillation column at the University of Tennessee is plotted in Figure 6. 11 Figure 6 – Product Concentration vs. Feed Pump Speed 100 y = -5.125x 2 + 49.5x - 27.375 R2 = 1 Product Concentration (vol% MeOH) 90 80 70 60 50 40 30 20 10 0 0 1 2 3 4 5 6 Feed Pump Speed Discussion We evaluated our experimental results according to our proposed objectives. In addition, we identified sources of error in our data and evaluated the report submitted by Rotation 1. Effect of Feed Flow Rate on Product Concentration We found a linear, positive correlation between the feed flow rate and the product concentration. This trend agrees with theory because as feed flow rate is increased, the flow rate increases in turbulence. Mass transfer is improved with a more turbulent flow resulting in increased distillate composition of product. Due to equipment problems, we were unable to measure distillate composition when the flow rate was high enough to cause flooding to occur. However, we would expect that distillate composition would continue to increase with increasing flow rate until flooding. During flooding, the contact between the liquid and vapor phases is dramatically decreased, therefore, we would expect mass transfer and hence distillate composition to be decreased as well. Effect of Feed Flow Rate on Mass Transfer Coefficient (Kog) We found a linear, negative correlation between the feed flow rate and mass transfer coefficient, which is also consistent with theory. This is because the mass transfer coefficient as derived by6 is actually a resistance to mass transfer. Thus, as mass transfer capability increases, the mass transfer coefficient should decrease. 12 Effect of Feed Temperature on Product Concentration and Mass Transfer Coefficient Feed temperature did not have a significant effect on distillate composition or mass transfer coefficient. All of our runs were completed only within the fairly small temperature range of 25-45˚C. This is due partly to equipment difficulties, preventing us from collecting additional data at higher temperatures within the available time frame. Also, we chose 45˚C as the maximum temperature because at high flow rates (550 mL/min), we were unable to reach temperatures higher than 45˚C. Therefore, we maintained this temperature range to be consistent across all flow rates. Because this temperature range is so small, it is possible that there was just not a large enough difference to see any trend on a plot of feed temperature versus product concentration or mass transfer coefficient. Another possible explanation is that although at higher temperatures, there will be more vapor flowing through the enriching section of the column, it is uncertain what the composition of this vapor will be. While there may be increased total moles of methanol in the vapor phase, there will also be increased total moles of water. Thus we are unable to predict whether the product concentration should be significantly changed with different feed temperatures without further experimentation. We recommend that future experimentation include obtaining data at a wider range of temperatures for the low flow rate (150 mL/min). Also, the reboiler adds a large amount of heat to the system. It is possible that the effects of the changing feed temperature are insignificant compared to the heat provided by the reboiler. This may also explain the lack of correlation we found from our results between feed temperature and distillate composition (and mass transfer coefficient). Flooding We confirmed the findings of Rotation 1 that reboiler power and feed flow rate would have the greatest effect on flooding. We also extended the experimentation completed by Rotation 1 by testing the effect of reflux ratio on flooding. We found no difference in flooding conditions between reflux ratios of 6.7 and 46. The data found by Rotation 1 was compared to the Wilkes and Pro-pak flooding correlations (Appendix I). While the trends were similar, the actual numbers were not. Rotation 1 attributes this to the numerous assumptions (constant densities throughout column equal to the liquid and vapor densities at the top of the column, linear combination of the densities of the mixtures valid, liquid and vapor have equal molar compositions). A possible source of error in our data is in our definition of flooding. Flooding was defined as occurring when the liquid holdup reached 6 inches above the center feed, similar to Rotation 1. This definition is fairly subjective and is difficult to expand to other distillation columns without experimentation. Due to equipment limitations, we were unable to predict flooding as a function of pressure drop. However, a correlation based on pressure drop would be more useful if extending to other distillation columns. Therefore, we recommend in the future for users to attempt to determine a flooding correlation that is based on the pressure drop, p. 13 Constant Molal Overflow Assumption versus Enthalpy-Concentration Method We determined that the constant molal overflow assumption is valid for this distillation column. This is because the latent heats of vaporization for methanol and water are nearly equal (methanol: 40657 kJ/mol; water: 35210 kJ/mol). If this difference were significant, then if the enthalpy-concentration method were used, this would result in curved operating lines. We generated a T-x-y plot using a representative set of data with both the McCabe-Thiele method (constant overflow assumption) and the enthalpy-concentration method (Appendix J). Because these two graphs are very similar, with almost straight operating lines with the enthalpy-concentration method, this confirmed the validity of the constant molal overflow assumption. Distillation Model Rotation 1 provided a model to determine KOG using theoretical equations and to plot a McCabe-Thiele diagram. We adapted this model to determine optimum flow rate for a specified distillate composition. We also extended this model to better fit our data by first calculating values for KOG theoretically, then fitting our experimental data to a regression model using Polymath to determine KOG as a function of feed flow rate and reboiler power (Equation 20). Feed flow rate and reboiler power were chosen because they appeared to have the strongest effect on product concentration. KOG = 2123.5·(feed flow rate)-0.933·(reflux ratio)-0.552 (20) By fitting our data to a model, this allowed us to more realistically account for changes in KOG due to changes in the column conditions. This model takes inputs of reflux ratio, reboiler power, and distillate composition, and determines what flow rate the column should be set at to achieve this distillate composition. It will provide warnings if this column is not capable of reaching this distillate composition within the flow rates we tested (100-550 mL/min) or if flooding will occur. A detailed description of the model is found in Appendix F. Figure 7 compares experimental data (for Run 1) to data obtained using the model. This confirms the validity of this model because the experimental and theoretical values are comparable (within 25%) 14 Figure 7 – Experimental vs Model (for Run 1 Conditions) 1 Distillate Composition (vol%) 0.9 xd, model 0.8 xd, expt 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 0 100 200 300 400 500 600 Feed Flow Rate (mL/min) Evaluation of University of Tennessee-Chattanooga Online Distillation Column We assessed the usability of the online tray distillation column designed by the University of Tennessee, Chattanooga (UTC). Overall, we found the column easy to use and were impressed by the extensive real-time data available for us to download. We felt the following changes would facilitate use of this column for diverse users: Clarify the feed location on the diagram: The diagram looks as if the feed port is at the top of the column. In addition, it looks as if there are two other possible feed ports (in the middle and bottom). We were informed that the feed is currently at the middle, however. We thought the actual location of the feed should be made clearer on the diagram. Also, we were uncertain if it were possible to change the feed location if we contacted UTC or if the feed location can only be in the middle. Label and improve the lighting of the real-time pictures: We felt we would be able to understand the pictures better if they were labeled with which part of the column they are. Also, it is difficult to see the pictures unless either the room lights are on or the blinds are open. We felt that if it were possible, improved lighting would also help clarify the pictures. Provide a correlation to convert the feed pump scale to an actual flow rate: Currently, the feed flow rate is indicated only by a unitless integer scale. In terms of data analysis, we felt that it would be useful to either indicate what the actual flow rate is (in volume/time) on the interface or to have a correlation to determine actual flow from the unitless scale. Show reflux as reflux ratio rather than reflux percent (on the graphical control panel): Because many theoretical equations use reflux ratio rather than reflux percent, we felt it 15 would helpful to express this variable as reflux ratio to facilitate data analysis and when choosing what column settings to use. Provide a better visual and/or audio alert at automatic column shut-down after 15 minutes of use: An alert to inform the user that the column is shutting down would be helpful to prevent having to re-establish steady-state if the user did not press start immediately after automatic shut-down occurred. Show numerical values of additional temperatures on the figure (eg. the top tray temperature and feed temperature): We thought it would be helpful to have numerical values of additional temperatures displayed on the column diagram. Although it would probably seem too cluttered if temperatures of all trays were provided on the screen, we thought it would be useful to have the temperature of the top tray to enable the user to determine the distillate concentration. It would also be helpful to have the feed temperature shown on the screen to more easily determine the feed quality. In general, we felt that this column was very well designed and clear to use. We found a second order correlation between feed rate and composition with the Tennessee column. This is in contrast to our experimental data collected in the Brown Industries lab. One possible reason for this might be that we do not know the actual flow rates with the Tennessee column and therefore it is difficult to determine whether we were operating at the same ranges. We operated our column at conditions well below flooding. If the Tennessee column were at or close to flooding at the higher flow rates, this would result in a leveling off of the composition-feed rate curve due to limited mass transfer. Also, to determine the distillate composition of the Tennessee column, we had to calculate the composition from the top tray temperature, rather than analysis by a GC. This may also have resulted in the difference between the Tennessee column and the Brown Industries data. Error In this rotation, we determined that the main source of error is in manually keeping the set point values constant on the distillation column. On the distillation column, the set point for the reflux ratio was hard to keep constant since the control was manual. Changes in the level of distillate collected in the receiver made it difficult to maintain steady-state; this may have affected our calculations. Another possible source of error is that because the feed tank was not continuously stirred, there may have been a separation of methanol and water due to their different densities (methanol: 0.79 g/cm3; water: 1 g/cm3). This would result in a non-constant feed concentration leading to error in the concentration measurements and error in the model. Lastly, the GC calibration and readings were inaccurate (+/- 2 vol% as determined by Rotation 1), and this would lead to inaccuracies in our calculations. Critique of Rotation 1 The final report provided by Rotation 1 was overall very thorough and detailed. Each objective was completed and presented in a planned and organized manner. Their error 16 analysis regarding the gas chromatograph was useful in determining the reliability and accuracy of the instrument. Rotation 1’s flooding analysis was quite comprehensive, especially their presentation of experimental versus theoretical (i.e. Wilkes) values. We found three aspects of Rotation 1’s report that could be improved. First, the experimental design regarding quantifying the effect of reflux ratio and reboiler power on the distillate composition seems to be rather limited in scope. The ranges for both independent variables are small and more useful correlations could have been developed for a wider range of values. Second, Rotation 1 claimed that no correlation existed between distillate composition and reboiler power. However, the reported higher reboiler power values (> 70%) are at or above flooding conditions. By removing these points, a correlation between these variables can be developed. Third, after analyzing the computer module that Rotation 1 developed to produce McCabe-Thiele plots, it seems that their program determines the number of stages to step off by determining how many stages are needed to reach the bottoms concentration (xw) calculated by the mole balance rather than using the calculated value for NOG. They did not include a check to ensure that the number of stages calculated by NOG equals the number of stages needed to reach the calculated xw. Therefore, their model would only be accurate if all parameters are set from empirical data, and they would not be able to determine if their empirical data is flawed using their model. Conclusions and Recommendations To conclude, we were able to complete all of our objectives. For the concentration and mass transfer coefficient, we found that as the feed rate was increased the concentration of methanol increased and the mass transfer coefficient decreased, and there was no correlation with feed temperature. Furthermore, we were able to correlate the feed flow rate and reflux ratio to the mass transfer coefficient using Polymath. We also determined that there was no correlation with reflux ratio to flooding and found that the correlation for flooding from Rotation 1 was accurate. We decided that we can use the molar overflow assumption for our model because the difference between the latent heats of vaporization of methanol and water is negligible. Therefore, we were able to create a model on Excel where the reflux ratio, reboiler power, feed weight fraction, feed temperature, and distillate weight fraction can be inputted, and the model will calculate the changes in the mass transfer coefficient, whether or not flooding will occur and the appropriate feed flow rate to be used. Lastly, when evaluating the online tray distillation column simulation from the University of Tennessee, we have determined that it is a good simulation, but there are some changes that can be made. After completing our objectives, we have several recommendations. First, we suggest that the column be run at a wider range of temperatures to find better correlations. Also, there should be a stronger feed preheater, so the feed will be able to enter the distillation column at the saturation point for higher flow rates. This would lead to a better correlation. Next, we suggest that the feed placement in the distillation column be evaluated. Additionally, the feed tank should be stirred more frequently to prevent separation of methanol and water due to the difference in the densities of the components. Also, when trying to determine when steady state has been reached, it should be determined by a constant level in the distillate receiver. We also recommend for the determination of a flooding in the column be based on the pressure drop, 17 p. To facilitate this p measurement, the data acquisition should be faster so the change in pressure can be read in smaller intervals. We also recommend that automatic controls be installed to adjust the reflux and the distillate flow rates to minimize the fluctuation that occurs when adjusting these values manually. This would prevent the inaccuracies in measurement and identifying when steady state has been reached. We also recommend that a better GC with less error be purchased in order to produce more accurate results. References 1 Simons, E., Soares, S., and L. Soland Distillation Final Report – Rotation 1 10/7/02 2 Brown Industries. ChE 460 Equipment Manual: “Technovate Pilot-Scale Distillation Column.” 2002. 3 Wilkes, JO. Fluid Mechanics for Chemical Engineers. Prentice-Hall Inc. New Jersey. 1999. 4 Geankopolis, CJ. Transport Processes and Unit Operations, Third Edition. Prentice-Hall, Inc. New Jersey. 1993. 5 Perry, RH and Green, DW. Perry’s Chemical Engineers’ Handbook Seventh Edition. McGrawHill. New York. 1997. 6 Lecture 1-Distillation, Fogler lecture notes from September 9, 2002 18 Appendix A: Nomenclature Table Symbol cp D Hsol F gc H h Lm, Ln m Mg Ml n q qC qR R T Vm, Vn W x XLG y YLG Description Heat capacity Distillate flow rate Heat of solution Packing factor (Wilkes, 1999) Conversion factor, 32.2 Enthalpy of vapor Enthalpy of liquid Liquid flow rate in column Tray m in stripping section Gas mass velocity Liquid mass velocity Tray n in enriching section Quality of feed (q=1 when saturated liquid) Energy removed by condenser Reboiler duty Reflux ratio Temperature Vapor flow rate Bottoms flow rate Liquid mole fraction Independent variable on flooding curve Vapor mole fraction Dependent variable on flooding curve L g l Latent heat of vaporization Liquid viscosity Gas density Liquid density Density of water divided by density of liquid Units J/kg K mol/hr kJ/mol --lbm ft/lbf s2 btu/lbm or kJ/kg btu/lbm or kJ/kg mol/hr --lbm/ft2 s or kg/s m2 lbm/ft2 s or kg/s m2 ----btu/hr or kJ/h btu/hr or kJ/h --°C mol/hr mol/hr mol product/total mol liquid --mol product/total mol vapor (lbm/ft2 s)(cP0.2)/ [(lbm/ft3)2(lbm ft/lbf s2)] kJ/kg mol cP lbm/ft3 or kg/m3 lbm/ft3 or kg/m3 --- 19 Appendix B1: Explanation of Calculations McCabe - Thiele Diagram and Mass Transfer Coefficient We needed to calculate a mass transfer coefficient for all of our runs as well as generate a McCabe-Thiele diagram. The following shows how we carried out these calculations and a sample calculation. The sample calculation is based on the following conditions that were observed in lab: Reflux rate (ml/min) Distillate rate (ml/min) Feed concentration (vol%) Feed rate (ml/min) Top column temperature (°C) Feed temperature (°C) Reboiler Power % Distillate concentration (vol%) 99 21 5.1% 530 83.1 24.22 50 86.6% Table B.1: Data used in Sample calculations First, we needed to calculate the quality of the feed stream. In order to do this we used the following equation4. q Hv H f (B-1) Hv Hl Hv= Enthalpy of feed as a vapor at saturation temperature. Hf= Enthalpy of feed. Hl= Enthalpy of feed as a liquid at saturation temperature. To calculate Hv – Hf heat of mixing was neglected and the following equation was used. Tb Tb H v H f n H 2O C pH2O vH 2O nmethanol C pmethanol vmethanol T T f f H v H l n H 2O vH 2O nmethanol vmethanol (B-2) (B-3) C pH 2O = Heat capacity of water= 2.33 + 7.82E-3 * T + 3.77E-5 * T2 C pmethanol =Heat capacity of methanol= 4.188 - 5.69E-4 * T - 8.49E-6 * T2 vH 2O =Heat of vaporization of water=2481.8 - 1.821 * T- .004236 * T2 vmethanol =Heat of vaporization of methanol=1218.4- 1.3849 * T- .006402* T2 (Binarysee below) 20 For the Cp and v calculations T is in °C. Sample Calculations: For our system, using the equations above: 94.64b 94.64 H v H f n H 2O C pH 2O vH 2O nmethanol C pmethanol vmethanol 24.22 24.22 nmethanol= (converting volume fraction to mol fraction) .0234 nH2o= 1-.0234=.9766 (B-4) Hv-Hf= 2521.71 kJ/kg H v H l n H 2O vH 2O nmethanol vmethanol with T=94.64°C (from TXY diagram) Hv- Hl= 2231.6 kJ/kg Therefore, q= 1.13 We then used the values that we observed in lab for xD, D, L, F and xF to calculate xB, B and the slope and intercepts of all the operating lines as described below. To calculate B and xB we used the following equations derived from a mass balance. B= F-D xB (B-5) x f * F xD * D B (B-6) Since for all of our runs, the GC could not detect the concentration of methanol in the bottoms, we assumed that xB <.02 for all runs, and checked this to ensure a proper mass balance. Sample Calculation: For our system: First we converted the volume concentrations and fractions to molar concentrations and mol fractions. We assumed no change in volume in order to do this. B= 28.71 mol/min-.98 mol/min= 27.73 mol/min .0234 * 28.71 .78 * .9766 xB .0079molmethanol / moltotal 27.73 To calculate the equation for the q-line the following method was used: The equation for the q-line is4: x q y x F (B-7) q 1 q 1 21 We found the slope and intercept for this line using the calculated value of q, the experimental value of xF , and the equation above. Sample Calculation: q 1.13 Slope 8.63 q 1 1.13 1 intercept x F .0234 .18 q 1 1.13 1 (B-8) (B-9) To calculate the equation for the enriching line the following method was used: The equation for the enriching line is4: y x R x D R 1 R 1 (B-10) We found the slope and intercept for this line using the equation above, calculated values for R (R=L/D), and experimental values for xD. Sample Calculation: R 4.7 slope .82 R 1 4.7 1 intercept xD .0234 .13 R 1 4.7 1 (B-11) (B-12) To calculate the equation for the stripping line, the following method was used: The equation for the stripping line is4: y Lm B x xB Gm Gm (B-13) Lm q * F L (B-14) Gm ( L D) (1 q) * F (B-15) We found the slope and intercept for the stripping line using the equations above along with experimental values of xB, F and L and calculated values of q. Sample Calculation: Lm q * F L =1.13*28.71+5.48=37.92 mol/min Gm ( L D) (1 q) * F =(5.48+.9766)-(1-1.13)*28.71=7.79 mol/min 22 slope Lm 38.35 4.87 Gm 7.79 B 29.17 * xB * .00703 .03 (B-16) Gm 9.17 Once the equations for all the lines were generated, we checked to ensure that the lines intersected at the same point, then verify the placement of the feed and also to determine xa, the intersection of the stripping and enriching lines. We then plotted the lines on a Txy diagram (using an excel spreadsheet) in order to generate a McCabe Thiele diagram. intercept Sample Plot: McCabe Thiele Diagram 1 0.9 0.8 0.7 y 0.6 0.5 0.4 equilibrium data y1=x1 enriching line stripping line q-line stages 0.3 0.2 0.1 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 x Figure B.1: Sample McCabe Thiele Diagram Once a McCabe- Thiele diagram was generated, we found Nog using the following equation4: yD N og dy y *y (B-17) yB We found values of y and y* using the equations for the operating lines and the Txy diagram 1 respectively. We then used Simpson’s rule to integrate the area under the curve for v y. y y* For our data, we found a Nog value of 3.78. 23 We found Hog using the equation below H og H N og (B-18) Sample Calculation For our data H og H 76.2cm 20.16cm N og 3.78 We then calculated the mass transfer coefficient, Kog, using the following equation K og H og * G ' (B-19) Sample Calculation K og H og * G ' =20.16cm*0.074 mol/cm^2=1.50 mol/cm Source: “Binary Distillation Using Random Packing” http://www.ualberta.ca/CMENG/courses/che454/handouts/jan2002/dist.doc. University of Alberta. (Date accessed: September 20, 2002) 24 Appendix C: Flooding Correlations Wilkes A theoretical correlation to model flooding can be plotted with Equations C-1 and C-23. X LG Ml Mg G L M g2 Fl0.2 YLG g l gc (C-1) (C-2) The independent variable in Equation 1 is XLG, which is based on the relationship between the gas and liquid velocities. The dependent variable, YLG, is the square of the gas mass velocity multiplied by a constant that takes into account the fluid densities, the packing factor, and the liquid viscosity. On a plot of YLG versus XLG, the region above the curve predicts conditions when flooding occurs, while the region below the curve predicts normal conditions. Pro-Pak There is also a model found in the Pro-Pak packing material literature which relates the vapor velocity to flooding (Equation C-3). MG = 270(ρ1)0.58(ρ2)0.42 (C-3) 25 Appendix D1: Flooding Analysis and Sample Calculations In order to compare the flooding points to data from literature, a number of calculations were necessary. The following equations were used. Molar flow rate of gas (G): (D-1) G L D L is the liquid from the reflux and D is the distillate. Based on the top-column temperatures, the methanol concentration in the distillate and the reflux was determined from the T-x-y diagram. The volumetric flow rates of reflux and distillate were monitored. Conversion between molar and volumetric methanol fraction: 1 v MeOH x MeOH MWMeOH (D-2) MeOH MWMeOH is the molecular weight of methanol. ρMeOH is the density of liquid methanol Mass flow rate of gas (Mg): M G G xMeOH MWMeOH x H 2O MWH 2O xi is the mole fraction in the distillate and reflux. Molar flow rate of liquid (L): RG L 1 R R is the reflux ratio L R D Mass flow rate of liquid (ML): M L Lx MeOH MW MeOH x H 2O MW H 2O Mass fraction of MeOH (mMeOH): xMEOH MWMEOH mMeOH xMeOH MWMeOH xH 2O MWH 2O (D-3) (D-4) (D-5) (D-6) (D-7) Density of gas phase (ρG), assuming that density is independent of mixing and that each component fraction is at its saturation point: G mMeOH MeOH ( g ) mH 2O H 2O ( g ) (D-8) ρi(g) is the density for saturated vapor. 26 Density of liquid phase (ρL), assuming that density is independent of mixing and that each component fraction is at its saturation point: L mMeOH MeOH (l ) mH 2O H 2O (l ) (D-9) ρi(l) is the density for saturated liquid. Flooding correlation from Pro Pack manual: 0.58 0.42 (D-10) M G 270 L G To compare this predicted value to the actual experimental results, the densities used were calculated by using the measured mass fractions of methanol and water (see eq. D-8 and D-9) The results were multiplied by relevant constants to ensure that the units were the same Graphical correlation from Wilkes3 The independent variable on the graph is FLG G M FLG L M G L (D-11) The dependent variable (ywilkes’) is calculated from eq. (D-12) 2 0.2 M F l yW ilkes' G (D-12) G L g c F is packing factor, H 2O / L , μl is liquid viscosity and gc = 32.2 lbmft/lbfs2 (conversion factor). [MG] = lbm/ft2s, [ρi] = lbm/ft3 For these experiments: F = 372 ft-1 [1], μl = 0.3 cP (value for water) [2] Area of column (A): 2 1.5in 0.05 ft 2 A 12in / ft The inner diameter of the column is 3 in. (D-13) Sample calculations Table D.1 shows a set of data that is used in the sample calculations while Table D.2 is a list of used constants. Table D. 1: Experimental Data Top column temperature (ºC) 93.56 xMeOH L (ml/min) D (ml/min) 0.23 377.97 6.37 Table D.2: Table of used constants 3 Vapor densities (kg/m ) MeOH H2O 1.222 0.5975 Liquid densities (kg/m3) MeOH H2O 751.0 958.39 Molecular weights (g/mole) MeOH H2O 32.04 18.016 27 Molar gas flow rate G 16.67mole / min M G 16.670.23 32.04 0.77 18.016 0.354kg / min 0.265lb /( ft 2 s) calculating the final term by using the area of the column 377.97 R 59.3 6.37 59.3 16.67 L 16.4mole / min 1 59.3 M L 16.40.23 32.04 0.77 18.016 0.349kg / min 0.23 32.04 m MeOH 0.35 0.23 32.04 0.77 18.016 G 0.35 1.222 0.65 0.5975 0.82kg / m 3 0.051lb / ft 3 L 0.35 751.0 0.65 958.39 886.4kg / m 3 55.3lb / ft 3 Flooding correlation from Pro Pack manual (unit defined in manual): 0.58 0.42 M G 27055.3 0.051 791.6lb /( h ft 2 ) Graphical correlation Independent variable 0.348 0.814 FLG 0.0298 0.354 886.4 Dependent variable 958.39 0.264 2 372 0.30.2 886.4 yW ilkes' 0.245 0.051 55.3 32.2 28 Appendix E: Enthalpy-concentration method Equations E-1 and E-2 give the enriching section operating line and stripping section operating line, respectively y n1 y Ln Dx D xn Vn1 Vn1 Lm Wx xm w Vm1 Vm1 (E-1) (E-2) Equation E-3 is used to determine values for Vn+1 and Ln Vn1 H n1 (Vn1 D)hn V1 H1 LhD (E-3) V1 and Ln can be calculated if the reflux ratio is first set. H1 and hD can be determined by equations for the saturated vapor enthalpy (Equation E-4) and saturated liquid enthalpy (Equation E-5), respectively. H y A [ A c py A (T T0 ) (1 y A )[ B c pyB (T T0 )] (E-4) h xA c pA (T T0 ) (1 x A )c pB (T T0 ) H sol (E-5) Alternatively, this data can be obtained from an enthalpy-concentration plot which can be constructed by methods previously described4. A trial and error approach must then be used to determine Hn+1, which is necessary to plot the operating line. Details describing the use of the enthalpy-concentration method to find distillate composition can be found in Geankopolis4 and is summarized below: 1. Assume a value for xn. Assume Vn+1=V1=L+D and Ln=L. Use Equation E-1 to calculate yn+1, assumed. 2. Using calculated yn+1 and assumed xn, determine values for Hn+1 and hn by Equations E-4 and E-5, respectively. Using these values, determine Vn+1 by Equation E-3. Determine Ln by Equation E-6. Vn1 Ln D (E-6) 3. Using calculated values, determine yn+1 by Equation E-1. 4. If the calculated value of yn+1 does not equal yn+1, assumed, then use the calculated value for yn+1 and repeat steps 2 and 3. If the old calculated value for yn+1 is not close to the new calculated value for yn+1, assume another value for xn and repeat steps 1-4. 29 5. Plot the curved enriching-section operating line (Equation E-1) using the value for Hn+1 determined by the trial and error approach. The stripping-section operating line is given by Equation E-2 above. An enthalpy balance is done on the stripping section, given by Equation E-74. Vm1 H m1 (Vm1 W )hm q R Whw (E-7) An overall enthalpy balance on the entire system is given by Equation E-8. q R DhD WhW qC FhF (E-8) Using a similar trial and error method as described for the enriching-section, the strippingsection operating line can be determined. As described by Geankopolis4, first, assume a value for ym+1, then calculate xm with Equation E-2. Vm+1 and Lm are then calculated from Equations E-7 and E-9, respectively. Lm W Vm1 (E-9) Equation E-2 is then used to determine xm. This calculated value for xm is then compared to the assumed value for xm. If the values are close, then the calculated values for Vm+1 and Lm can be used in the stripping-section operating line. 30 Appendix E (cont.): Enthalpy-concentration chart data Data for Enthalpy-c oncentration c hart for methanol-w ater s ys tem Cp (J/mol K) kJ/mol Component BP (deg C) liq v apor latent heat of vap methanol (A) 64.6 81.1 44.1 40.657 w ater (B) 100 75.3 33.6 35.21 referenc e T: 64.6 xA yA xB 0 Tbp 1 0 0.25 0.25 0.5 0.5 0.5 0.75 1 x, y 0 0.25 0.5 0.75 1 0 0.25 0.5 0.75 1 0.75 1 h 100 64.6 79.5 93 73.1 85 68.5 74 64.6 0 h (liquid) H (vapor) Tie lines 2665.62 1143.575 664.7 310.635 0 37875.62 39719.425 39948.63 40165.785 40657 0.1 0.418 2056.802 39873.451 0.3 0.665 1047.8 39765.266 0.5 0.779 644.7 40222.766 0.7 0.87 381.448 40122.354 0.9 0.958 124.254 40574.476 0.02 0.134 2543.8564 38863.899 lambdaB H 2665.62 36686.18 37875.62 36686.18 39719.425 36686.18 39948.63 1143.575 664.7 310.635 36686.18 0 40165.785 40657 pure methanol Perry 's T-x -y data: Temp (C) x1 100 96.4 93.5 91.2 89.3 87.7 84.4 81.7 78 75.3 73.1 71.2 69.3 67.5 65.9 65.1 64.5 y1 y 1=x1 0 0.02 0.04 0.06 0.08 0.1 0.15 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 0.95 1 0 0.134 0.23 0.304 0.365 0.418 0.517 0.579 0.665 0.729 0.779 0.825 0.87 0.915 0.958 0.979 1 0.25 0.75 0.04541 0.442 0.1414 0.662 0.8925 0.25 0.75 0.5 0 0.02 0.04 0.06 0.08 0.1 0.15 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 0.95 1 31 Appendix E (cont.): Enthalpy-concentration chart for methanol-water Enthalpy concentration plot for methanol (A)-water (B) enthalpy of mixture (kJ/mol) 45000 40000 35000 30000 h (liquid) H (vapor) Tie lines 25000 20000 15000 10000 5000 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 xA, yA 32 Appendix E (cont.): Enthalpy concentration method calculation for Run 3 Vm+1,calc (mol/min) Lm, calc (mol/min) ym+1, calc (mol frac) yn+1, calc (mol frac) 0.11 0.20 0.37 0.54 0.71 0.80 0.88 0.97 hm (J/mol) Ln, calc (mol/min) 123 119 112 111 109 108 107 105 Hm+1 (J/mol) Vn+1,calc (mol/min) 143 139 132 131 129 128 127 125 qC (J) hn (J/mol) 2500 2400 1000 665 300 225 150 0 hF (J/mol) Hn+1 (J/mol) 38000 39000 39800 39900 40000 40250 40500 41000 hw (J/mol) hD (J/mol) -2364 -2364 -2364 -2364 -2364 -2364 -2364 -2364 hm (J/mol) H1 (J/mol) 40827 40827 40827 40827 40827 40827 40827 40827 Hm+1 (J/mol) F (mol/min) 550 550 550 550 550 550 550 550 F (mol/min) xD (wt frac) 0.866 0.866 0.866 0.866 0.866 0.866 0.866 0.866 qR (J) mD (mol frac) 0.785 0.785 0.785 0.785 0.785 0.785 0.785 0.785 xw (mol frac) D (mol/min) 20 20 20 20 20 20 20 20 W Vn+1=V1 (mol/min) 120 120 120 120 120 120 120 120 Vm+1 Ln (mol/min) 100 100 100 100 100 100 100 100 Lm xn 0 0.1 0.3 0.5 0.7 0.8 0.9 1 xm 0.131 0.214 0.381 0.547 0.714 0.797 0.881 0.964 ym+1 yn+1 Tref=64.6 deg C 0.008 0.024 0.055 0.087 0.119 0.151 0.167 0 0.1 0.3 0.5 0.7 0.9 1 100 100 100 100 100 100 100 630 630 630 630 630 630 630 530 530 530 530 530 530 530 0.00931 0.00931 0.00931 0.00931 0.00931 0.00931 0.00931 5E+06 5E+06 5E+06 5E+06 5E+06 5E+06 5E+06 550 550 550 550 550 550 550 36334 36426 36609 36793 36977 37160 37252 -2229 -2246 -2280 -2315 -2349 -2383 -2401 -3436 -3436 -3436 -3436 -3436 -3436 -3436 -2989 -2989 -2989 -2989 -2989 -2989 -2989 4862943 4862943 4862943 4862943 4862943 4862943 4862943 35500 36000 38500 39500 39800 39900 40000 2500 2400 1000 665 300 150 0 243 237 193 182 174 170 167 773 767 723 712 704 700 697 -0.02 0.30 1.10 1.93 2.81 3.67 4.14 33 Appendix F: Distillation Model (Excel) Distillation Model INPUTS Feed Flow Rate Distillate Flow rate Reflux Flow rate Feed wt fraction Feed temp Distillate wt fraction Reboiler Power Warning (flooding) Feed vol fraction Distillate vol fraction Quality Feed mol flowrate Distillate mol flowrate Reflux mol flowrate Feed mol fraction Disitillate mol fraction Reflux Ratio Bottoms Flow (mol) Bottoms concentration q-line slope intercept Bounds Value 100 20 100 0.05 25 0.6 50 0.061875 0.65274725 1.13 13.76 0.70 3.52 0.03 0.46 5.00 13.05 0.005611 Units ml/min ml/min ml/min g methanol/g total oC g methanol/g total % volmeth/totalvol volmeth/totalvol mol/min mol/min mol/min molmeth/totalmol molmeth/totalmol 8.80 -0.22 x Reboiler Power y 3.18 -0.01 x y 0.01 0.11 0.83 0.08 x G' HOG NOG xw, calcd by Kog abs(xwMB-xwKOG) optimum F min error, xw status yintersection 0.04 0.04 0.04 1.45 45.72 cm 31.47 cm 2.91 mol/cm 74.04 0.76 0.46 -39.64% x xtoy 0.05 0.46 0.46 0.84 Flooding Conditions 88.9203 % Experimentally Determined 4.893416061 mol/cm 0.11 0.11 0.11 top + bottom Nog2 Ve Hog Kog 1.91 76.20 cm 39.98 cm 3.70 mol/cm q-line y 0.27 0.46 0.092653935 mol/(min*cm^2) 52.81390443 cm 1.442801869 plates 0.23 -0.04 1 Nstages, expt correlation (integer) 0.119857108 0.114246 (error) 259.000000 mL/min 0.000014 molmeth/totalmol these conditions should work! (for error(xw) < 0.01) y 0.46 0.04 Reference: Density of methanol Density of water KOG 0.03 0.11 0.01 0.04 Enriching Line slope Intercept Bounds Distillation point slope enriching Rmin mol/min molmeth/totalmol 0.03 0.04 Stripping line slope intercept Bounds xintersection q-line/strip inter qline/enrich inter strip/enrich inter only top Nog Ve Hog Kog Top temperature equil y y from GC Error 0.46 0.11 0.79 g/cm^3 0.99 g/cm^3 34 Appendix F: Distillation Model (Visual Basic Code) Module 1 'TXY data ' This declares the array Dim txy(17, 3) Sub start() 'This procedure declares the array 'This section puts the TXY Data 'in the form (a,b) the a stands for the row number 'and the b stands for the column ' '**IMPORTANT***, this procedure will interpolate data within the 'table, it will not give data at the endpoints or extrapolate data 'Declares the T data txy(1, 1) = 100 txy(2, 1) = 96.4 txy(3, 1) = 93.5 txy(4, 1) = 91.2 txy(5, 1) = 89.3 txy(6, 1) = 87.7 txy(7, 1) = 84.4 txy(8, 1) = 81.7 txy(9, 1) = 78 txy(10, 1) = 75.3 txy(11, 1) = 73.1 txy(12, 1) = 71.2 txy(13, 1) = 69.3 txy(14, 1) = 67.5 txy(15, 1) = 65.9 txy(16, 1) = 65.1 txy(17, 1) = 64.5 'Declares the X data txy(1, 2) = 0 txy(2, 2) = 0.02 txy(3, 2) = 0.04 txy(4, 2) = 0.06 txy(5, 2) = 0.08 txy(6, 2) = 0.1 txy(7, 2) = 0.15 txy(8, 2) = 0.2 txy(9, 2) = 0.3 txy(10, 2) = 0.4 txy(11, 2) = 0.5 txy(12, 2) = 0.6 txy(13, 2) = 0.7 txy(14, 2) = 0.8 txy(15, 2) = 0.9 txy(16, 2) = 0.95 txy(17, 2) = 1 35 'Declared the Y data txy(1, 3) = 0 txy(2, 3) = 0.134 txy(3, 3) = 0.23 txy(4, 3) = 0.304 txy(5, 3) = 0.365 txy(6, 3) = 0.418 txy(7, 3) = 0.517 txy(8, 3) = 0.579 txy(9, 3) = 0.665 txy(10, 3) = 0.729 txy(11, 3) = 0.779 txy(12, 3) = 0.825 txy(13, 3) = 0.87 txy(14, 3) = 0.915 txy(15, 3) = 0.958 txy(16, 3) = 0.979 txy(17, 3) = 1 End Sub 'Converts a T value to an X value Function ttox(Tvalue) start trigger = 0 'initiallizes the values to dummy values x1 = 10 x2 = 0 t2 = 10 t1 = 0 ' loops down the rows x=2 For x = 2 To 17 If trigger = 0 Then If (Tvalue >= txy(x, 1)) Then t1 = txy(x, 1) t2 = txy(x - 1, 1) x1 = txy(x, 2) x2 = txy(x - 1, 2) trigger = 1 End If End If Next x ttox = (x2 - x1) / (t2 - t1) * (Tvalue - t1) + x1 ' interpolates the data and sends it back to the cell End Function 'Converts a temperature to a y value Function ttoy(Tvalue) start trigger = 0 36 'initiallizes the values to dummy values y1 = 10 y2 = 0 x2 = 10 x1 = 0 ' loops down the rows For x = 2 To 17 If trigger = 0 Then If (Tvalue >= txy(x, 1)) Then x1 = txy(x, 1) x2 = txy(x - 1, 1) y1 = txy(x, 3) y2 = txy(x - 1, 3) trigger = 1 End If End If Next x ' interpolates the equilibrium data and sends it back to the cell ttoy = (y2 - y1) / (x2 - x1) * (Tvalue - x1) + y1 End Function 'Converts x values to y values Function xtoy(xvalue) start trigger = 0 'initiallizes the values to dummy values y1 = 10 y2 = 0 x2 = 10 x1 = 0 ' loops down the rows For x = 2 To 17 If trigger = 0 Then If (xvalue <= txy(x, 2)) Then x1 = txy(x, 2) x2 = txy(x - 1, 2) y1 = txy(x, 3) y2 = txy(x - 1, 3) trigger = 1 End If End If Next x ' interpolates the equilibrium data and sends it back to the cell xtoy = (y2 - y1) / (x2 - x1) * (xvalue - x1) + y1 End Function 'Converts y values to x values 37 Function ytox(yvalue) start trigger = 0 'initiallizes the values to dummy values y1 = 10 y2 = 0 x2 = 10 x1 = 0 ' loops down the rows For x = 2 To 17 If trigger = 0 Then If (yvalue <= txy(x, 3)) Then x1 = txy(x, 3) x2 = txy(x - 1, 3) y1 = txy(x, 2) y2 = txy(x - 1, 2) trigger = 1 End If End If Next x ' interpolates the equilibrium data and sends it back to the cell ytox = (y2 - y1) / (x2 - x1) * (yvalue - x1) + y1 End Function 'Converts x value to T value Function xtot(xvalue) start trigger = 0 'initiallizes the values to dummy values x1 = 10 x2 = 0 t2 = 10 t1 = 0 ' loops down the rows x=2 For x = 2 To 17 If trigger = 0 Then If (xvalue <= txy(x, 2)) Then t1 = txy(x, 1) t2 = txy(x - 1, 1) x1 = txy(x, 2) x2 = txy(x - 1, 2) trigger = 1 End If End If 38 Next x xtot = (t2 - t1) / (x2 - x1) * (xvalue - x1) + t1 ' interpolates the equilibrium data and sends it back to the cell End Function 'Converts y value to T value Function ytot(ytalue) start trigger = 0 'initiallizes the values to dummy values y1 = 10 y2 = 0 t2 = 10 t1 = 0 ' loops down the rows x=2 For x = 2 To 17 If trigger = 0 Then If (yvalue <= txy(x, 3)) Then t1 = txy(x, 1) t2 = txy(x - 1, 1) y1 = txy(x, 3) y2 = txy(x - 1, 3) trigger = 1 End If End If Next x ytot = (t2 - t1) / (y2 - y1) * (yvalue - y1) + t1 ' interpolates the equilibrium data and sends it back to the cell End Function 'Determines the quality of a feed given the temperature and concentration Function quality1(FeedTemp, FeedConc) start FeedX = molfrac(FeedConc) FeedsatTV = xtot(FeedX) FeedsatTL = ytot(FeedX) MethHeatV = 1218.4 - 1.3849 * FeedsatTV - 0.006402 * FeedsatTV ^ 2 H20HeatV = 2481.8 - 1.821 * FeedsatTV - 0.004236 * FeedsatTV ^ 2 CpH20 = 4.188 * (FeedTemp - FeedsatTV) - 0.5 * 0.000569 * (FeedTemp ^ 2 - FeedsatTV ^ 2) - (1 / 3) * 0.00000849 * (FeedTemp ^ 3 - FeedsatTV ^ 3) Cpmeth = 2.33 * (FeedTemp - FeedsatTV) + 0.5 * 0.00782 * (FeedTemp ^ 2 - FeedsatTV ^ 2) + 0.0000377 * (1 / 3) * (FeedTemp ^ 3 - FeedsatTV ^ 3) Hvhf = -CpH20 * (1 - FeedX) - Cpmeth * FeedX + MethHeatV * FeedX + H20HeatV * (1 - FeedX) Hvhl = FeedX * MethHeatV + (1 - FeedX) * H20HeatV quality1 = Hvhf / Hvhl 39 End Function 'Determined the hog using only enriching side Function Hog(Slopedist, interdist, xa, xd) Dim t(10100) start x = xa numsteps = 10000 Height = (xd - xa) / numsteps For N = 0 To numsteps ystar = xtoy(xa + N * Height) y = Slopedist * (xa + N * Height) + interdist t(N) = (1 / (ystar - y)) Next N H=0 g=2 int1 = 0 Do While g <= numsteps - 2 H = 4 * t(g) int1 = int1 + H g=g+2 Loop H=0 int2 = 0 R=1 Do While R <= numsteps - 1 H = 2 * t(R) int2 = int2 + H R=R+2 Loop inttotal = int1 + int2 + t(0) + t(numsteps) Hog = (1 / 3) * Height * inttotal End Function 'Calculates the HOg using both stripping and enriching lines Function Hog2(Slopestrip, interstrip, Slopedist, interdist, xb, xa, xd) Dim t(10100) start numsteps = 10000 Height = (xd - xb) / numsteps For N = 0 To numsteps xu = xb + N * Height ystar = xtoy(xu) If xu < xa Then y = Slopestrip * (xu) + interstrip End If If xu > xa Then y = Slopedist * (xu) + interdist 40 End If t(N) = (1 / (ystar - y)) Next N H=0 g=2 int1 = 0 Do While g <= numsteps - 2 H = 4 * t(g) int1 = int1 + H g=g+2 Loop H=0 int2 = 0 R=1 Do While R <= numsteps - 1 H = 2 * t(R) int2 = int2 + H R=R+2 Loop inttotal = int1 + int2 + t(0) + t(numsteps) Hog2 = (1 / 3) * Height * inttotal End Function Module 2 Function molfrac(volconc) rhoh20 = 0.99 rhometh = 0.79 molesh20 = (1 - volconc) * rhoh20 / 18 molesmeth = volconc * rhometh / 32.04 molfrac = molesmeth / (molesmeth + molesh20) End Function Function molvol(volflowrate, volconc) rhoh20 = 0.99 rhometh = 0.79 massh20 = (volflowrate * (1 - volconc)) * rhoh20 massmeth = (volflowrate * volconc) * rhometh molh20 = massh20 / 18 molmeth = massmeth / 32.04 molvol = molh20 + molmeth End Function Function volfrac(massconc) rhoh20 = 0.99 rhometh = 0.79 volh20 = (1 - massconc) / rhoh20 volmeth = massconc / rhometh 41 volfrac = volmeth / (volh20 + volmeth) End Function Function intersx(slope1, inter1, slope2, inter2) intersx = (inter2 - inter1) / (slope1 - slope2) End Function Function intersy(slope1, inter1, slope2, inter2) inters = intersx(slope1, inter1, slope2, inter2) intersy = slope2 * inters + inter2 End Function Module 3 Sub GoalSeekRmin() ' ' GoalSeekRmin Macro ' Macro recorded 10/3/2002 by Smeeta ' ' Range("I20").GoalSeek Goal:=0, ChangingCell:=Range("F20") End Sub Module 4 'TXY data ' This declares the array Dim xstage(16) Sub start() 'This procedure declares the array 'This section puts the X-stage Data 'in the form (a,b) the a stands for the row number 'and the b stands for the column ' '**IMPORTANT***, this procedure will interpolate data within the 'table, it will not give data at the endpoints or extrapolate data 'set dummy variables to zero xstage(1) = 0 xstage(2) = 0 xstage(3) = 0 xstage(4) = 0 xstage(5) = 0 xstage(6) = 0 xstage(7) = 0 xstage(8) = 0 xstage(9) = 0 xstage(10) = 0 xstage(11) = 0 42 xstage(12) = 0 xstage(13) = 0 xstage(14) = 0 xstage(15) = 0 xstage(16) = 0 End Sub ' determines bottoms concentration (xw) calculated by stepping off stages Function xwstages(xstage1, xstage2, xstage3, xstage4, xstage5, xstage6, xstage7, xstage8, xstage9, xstage10, xstage11, xstage12, xstage13, xstage14, xstage15, xstage16, N) start 'define equilibrium x values for each stage as an array xstage(1) = xstage1 xstage(2) = xstage2 xstage(3) = xstage3 xstage(4) = xstage4 xstage(5) = xstage5 xstage(6) = xstage6 xstage(7) = xstage7 xstage(8) = xstage8 xstage(9) = xstage9 xstage(10) = xstage10 xstage(11) = xstage11 xstage(12) = xstage12 xstage(13) = xstage13 xstage(14) = xstage14 xstage(15) = xstage15 xstage(16) = xstage16 'set dummy variables trigger = 0 For x = 1 To 16 If trigger = 0 Then If x = N Then xwstages = xstage(x) trigger = 1 End If End If Next x End Function Module 5 Sub findf() 'initialize variables ffinal = 0 43 bottomsmin = 1 bottomsset = 10 trigger = 0 For F = 100 To 550 If (trigger = 0) Then 'set F on spreadsheet to current value of F Range("B3").Select ActiveCell.FormulaR1C1 = F 'get value for difference between xwMB and xwKog bottomsmin = Range("F45") If (bottomsmin <= bottomsset) Then 'if value in cell (bottomsmin) is less than 'the set min in this fxn (bottomsset) then 'set bottomsset to the lower cell value bottomsset = bottomsmin 'set the flow rate at which the current 'bottomsset corresponds to ffinal = F 'display current minimum error and optimum F Range("F49").Select ActiveCell.Value = bottomsset Range("F48").Select ActiveCell.FormulaR1C1 = ffinal End If stopvalue = Range("F39") If (stopvalue = 0) Then trigger = 1 End If End If Next F If (bottomsset < 0.01) Then Range("F50").Select ActiveCell.FormulaR1C1 = "these conditions should work! (for error(xw) < 0.01)" Range("B3").Select ActiveCell.FormulaR1C1 = ffinal 44 Else Range("F50").Select ActiveCell.FormulaR1C1 = "distillate composition not attainable for these conditions (between F=100-550 mL/s)" End If End Sub 45 Appendix G: Equipment Diagram 16 14 Thermocouple s 13 9 Sample Port Q-3 C onde nser 7 Cooling Wat er 8 Feed Port 6 Fee d Prehe ater Turbine Flow-meter Column F PRV V-1 F s Reflu x Prehe ater 5 4 Q-2 F-4 s Disti llate Rece iver 3 2 Q-1 F F-5 Graduat ed flow meter 1 Reboiler 0 B-1 s R-3 R-4 10 12 B-2 11 Alternate Bott oms tank D-3 Alternate Dist illate tank C-1 D-4 Feed Tank Feed Pump F-1 F R-6 s B-3 D-2 15 R-1 s F-2 Alternate Fee d Ta nk R-2 Ref lux Pump D-1 46 Appendix H: MSDS of Methanol 47 Appendix I: Flooding Conditions Figure I-1: Vapor flow rate vs. Reboiler Power Vapor flow rate (kg/min) 0.43 R = 6.7 Pro Pack (R = 6.7) R = 46 Pro Pack (R = 46) 0.41 0.39 0.37 0.35 0.33 0.31 0.29 0.27 0.25 70 75 80 85 90 95 100 Reboiler power (%) *The flooding data from a reflux ratio of 6.7 is from Rotation 1. Figure I-2: Vapor flow rate vs. Feed Rate 0.45 R = 6.7 Pro Pack (R = 6.7) Vapor flow rate (kg/min) 0.43 0.41 R = 46 Pro Pack (R = 46) 0.39 0.37 0.35 0.33 0.31 0.29 0.27 0.25 60 160 260 360 460 560 660 Feed rate (ml/min) 48 Appendix I (cont.): Flooding Conditions Figure I-3: Wilkes vs. Experimental Flooding Conditions for reflux ratios of 6.7 and 46 1 Y axis Wilkes 0.01 0.1 R = 6.7 Wilkes R = 46 1 0.1 F LG 49 Appendix J: Constant Molal Overflow versus Enthalpy Concentration Method Figure J-1: McCabe Thiele Method Constant Molal Overflow Assumption (McCabe-Thiele Method) 1 y(methanol) 0.8 0.6 Equilibrium y1=x1 Enriching stripping q-line 0.4 0.2 0 0 0.2 0.4 0.6 0.8 1 x(methanol) Figure J-2: Enthalpy Concentration Method Enthalpy Concentration Method 1 y(methanol) 0.8 0.6 0.4 Enriching Stripping 0.2 Equilibrium y=x q-line 0 0 0.2 0.4 0.6 0.8 1 x(methanol) 50 51