PDSA's - The Michener Institute

advertisement

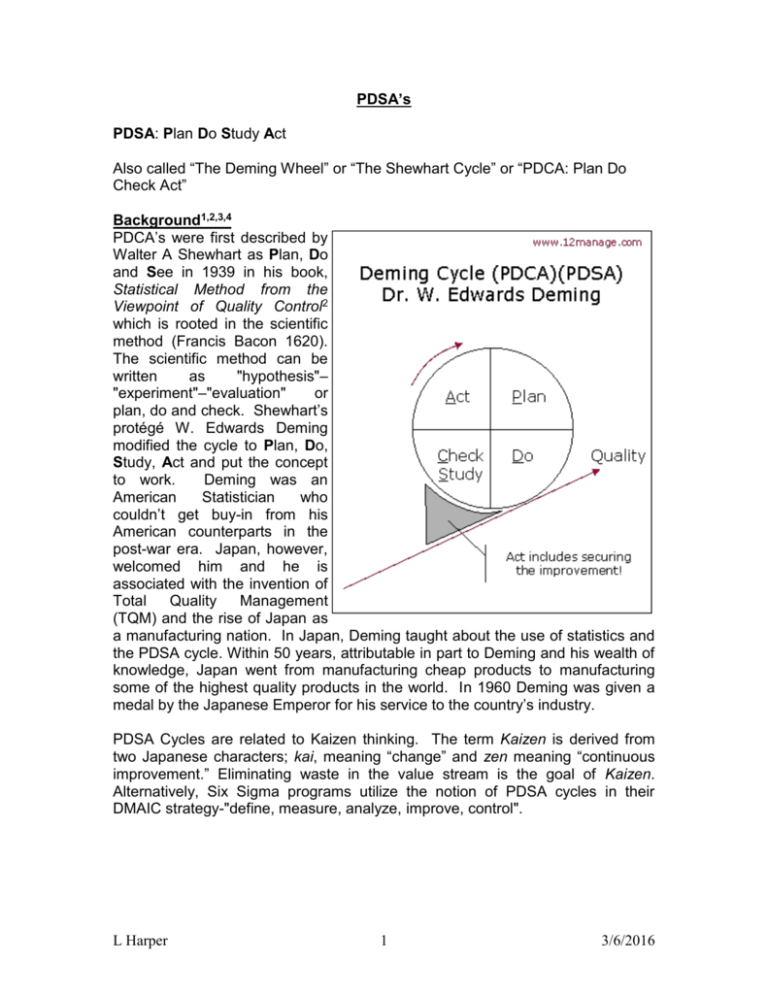

PDSA’s PDSA: Plan Do Study Act Also called “The Deming Wheel” or “The Shewhart Cycle” or “PDCA: Plan Do Check Act” Background1,2,3,4 PDCA’s were first described by Walter A Shewhart as Plan, Do and See in 1939 in his book, Statistical Method from the Viewpoint of Quality Control2 which is rooted in the scientific method (Francis Bacon 1620). The scientific method can be written as "hypothesis"– "experiment"–"evaluation" or plan, do and check. Shewhart’s protégé W. Edwards Deming modified the cycle to Plan, Do, Study, Act and put the concept to work. Deming was an American Statistician who couldn’t get buy-in from his American counterparts in the post-war era. Japan, however, welcomed him and he is associated with the invention of Total Quality Management (TQM) and the rise of Japan as a manufacturing nation. In Japan, Deming taught about the use of statistics and the PDSA cycle. Within 50 years, attributable in part to Deming and his wealth of knowledge, Japan went from manufacturing cheap products to manufacturing some of the highest quality products in the world. In 1960 Deming was given a medal by the Japanese Emperor for his service to the country’s industry. PDSA Cycles are related to Kaizen thinking. The term Kaizen is derived from two Japanese characters; kai, meaning “change” and zen meaning “continuous improvement.” Eliminating waste in the value stream is the goal of Kaizen. Alternatively, Six Sigma programs utilize the notion of PDSA cycles in their DMAIC strategy-"define, measure, analyze, improve, control". L Harper 1 3/6/2016 Quality Improvement (QI) QI can be looked at in a variety of ways. We can study, design and plan for long periods of time to create what we believe will be the best change strategy that is very involved and potentially risky and implement it OR, we can isolate and identify areas of improvement and test each of them in rapid succession using small tests where each test tries out various combinations of ideas. Small change tests can help isolate undesirable responses early and allow for modification without having invested too much into any given thing. Additionally, it is often easier to get buy-in for small changes one by one rather than changing the entire system all at once. QI asks5: 1. What are we trying to accomplish? 2. How do we know if the change is an improvement? 3. What changes can we make that will result in an improvement? Before you do a PDSA, do your homework5 1. Identify areas for improvement a. Source and read reviews of best practice b. Create process flow maps or diagrams to show where problems are and postulate potential solutions c. Use generic change concepts and then brainstorm how to apply them to the issue 2. Organize ideas into different groupings (change concepts) each with similar approach to change. 3. Prioritize change concepts 4. Identify possible variations in how each ideas concept could be implemented 5. Designate a PDSA ramp for each change concept. You can do each ramp one after the other or simultaneously. Application1,3,5,6,7 PDSA’s represent a means of systematic problem solving using a four-step process for continual improvement that can be used for almost any application and is meant to deliver immediate and noticeable improvement. PDSA cycles are used to test an idea by temporarily trialing a change and assessing its impact. This approach is unusual in many settings because traditionally, new ideas are often introduced without sufficient testing. PDSA cycles consist of a logical sequence of four repetitive steps: Plan, Do, Study (Check), Act. Using PDSA cycles enables you to test out changes before wholesale implementation and gives stakeholders the opportunity to see if the proposed change will work. L Harper 2 3/6/2016 Plan: Create a plan for change, develop a plan for improving quality at a process, analyze and predict the results o State the purpose of the test: identify specifically what are you trying to change? o Define the steps you need to make the change o Who/what/when/where/how many subjects? o Time period? o What are the indicators of success? o How will data regarding the success indicators be collected? o What do we thing will happen? Predict results/ Do: Execute the plan on a small scale, taking small steps to control circumstances o Carry out the test on a small scale in a controlled environment o Document any problems or unintended consequences, unexpected observations Study: Study the results, evaluate the feedback to confirm or adjust the plan o Analyze the data and study the results o Verify that you have improved the process o Compare the data to your predictions o Summarize and reflect Act: Take action to standardize or improve the process, make the plan permanent or study the adjustments o Refine the change based on the lessons learned from the test, determine what modifications need to be made o Implement the change you’ve verified on a broader scale. Update the Standard Operating Procedure. o Prepare the plan for the next test *NB: Document all PDSA cycles so you can reflect on changes that worked and led to improvement. Benefits of PDSA Cycles1 L Harper 3 3/6/2016 Daily routine management for the individual and/or the team; The problem solving process; Project management; Continuous development; Vendor development; Human resources development; New product development; Process trial. PDSA Ramps "PDSA ramps" can be designated for each change concept or grouping of similar ideas in which a series of related PDSA cycles are conducted to find the optimal way to implement the ideas and concepts within each ramp. Example of a Family Practice Trying to Improve Diabetes Care5 Within patient self-management, the team might try a series of PDSA cycles on any of the following5: giving a copy of the flow sheet to the patient at each visit giving a copy of the patient’s own run chart at each visit trying out different education materials or pamphlets use of group visits having a diabetes educator in the office on certain afternoons trying different versions of patient action plans Sample PDSA Worksheet 5 QI Project: PDSA Ramp (Change Concept or Ideas Being Tested): L Harper 4 3/6/2016 Start Date: Step 1: Plan Purpose of test: Measures of success: Data collection method: Subjects: # of subjects: Time period for test: Prediction of what will happen: Step 2: Do (Carry out the test.) Problems with conducting the test: Unintended consequences: Step 3: Study Results of test: How does it compare to predictions: Summary: Step 4: Act Next steps or PDSA cycle: References: 1. 12 manage. Deming Cycle (PDSA). Accessed online January 11, 2011 at: http://www.12manage.com/methods_demingcycle.html 2. Shewhart, Walter Andrew (1939). Statistical Method from the Viewpoint of Quality Control. New York: Dover. ISBN 0-486-65232-7. L Harper 5 3/6/2016 3. Sayer, NJ and Williams B. The Kaizen Project PDCA, or PDSA, Cycle of Lean. Accessed online January 11, 2011 at: http://www.dummies.com/how-to/content/the-kaizen-project-pdca-orpdsa-cycle-of-lean.html 4. PDCA. Wikipedia. 2011. Accessed online January 12, 2011 at: http://en.wikipedia.org/wiki/PDCA 5. Ontario Health Quality Council. Improvement: Testing and Implementing Change. Accessed online January 11, 2011at: http://www.ohqc.ca/en/change_2.php 6. SA Health Manager Wiki. PDSA Cycles. Accessed online January 12, 2011 at: http://sa-health.wikidot.com/pdsa-cycle 7. NHS Institute for Innovation and Improvement. Quality and Service Improvement Tools. Accessed Online January 12, 2011at: http://www.institute.nhs.uk/quality_and_service_improvement_tools/qu ality_and_service_improvement_tools/plan_do_study_act.html 8. Deming, W. Edwards (1986). Out of the Crisis. MIT Center for Advanced Engineering Study. ISBN 0-911379-01-0. L Harper 6 3/6/2016