murphree and vaporization efficiencies in multicomponent distillation

advertisement

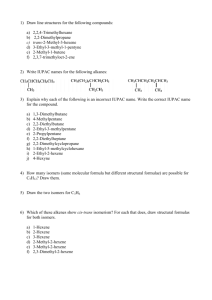

MURPHREE AND VAPORIZATION EFFICIENCIES IN MULTICOMPONENT DISTILLATION A G MEDINA,‘? N ASHTON and C MCDERMOTT Chemical Engmeermg Department, Umverslty of Birmmgham, Bummgham BlS, England (Recewed 19 Apnl 1977, accepted 14 June 1977) quantitative comparison between Murphree and vaponzatlon efficlencles IS presented based on ternary chstdlatlon data for the systems acetone/methanol/ethanol, acetone/benzene/chlorobenzene, benzene/toluene/mxylene and n-hexanelmethylcyclopentanelbenzene The Influence of expenmental errors on calculated values of Murphree efficiencies IS also analysed It IS shown that the vaporlzatlon efficiency model fads to descnbe the hehavlour of dlstdlatlon plates and It IS suggested that Murphree’s model grves a more useful representation of the behavlour of dlstdlatlon columns Abstract-A INTRODUCTION the design of dlsdlation columns the knowledge of accurate values of plate efficiencies 1s very Important as they have a direct effect on the number of plates required and an mdrrect effect on the runnmg costs of the eqmpment Murphree’s model[l7] was the first of several models leadmg to different efficiency defimttons Vapour phase Murphree efficiency for component I and plate n can be defined as In Ynr-Yn+lt %v,z= Y2 Y"+i I - (1) I where y “I and y,,+, 1are the mole fractions of component I m the vapour leaving and entering plate n respectively and y* , IS the mole fraction of component I In the vapour m eqmhbrmm with the hqmd leaving plate R @us liquid 1s considered to be a saturated hquld) The ongmal Murpbree defimtlon was generahzed by Taylor[20] allowing for unsaturated llquld and vapour streams Holland [ 11J defined the vaporlzatlon efficiency for component I and plate n as E vnI =- y”’ *t (2) where Y,,, = K,,, A,, x,, IS the mole fraction of component 1 in the hqmd leavmg plate n and K,, IS the vapour-hqmd equllrbnum ratio evaluated at the actual temperature and pressure at which hqmd leaves plate n Naturally Y,, , = y*nI If the hquld leavmg the plate IS a saturated liquid Several papers were pubhshed recently dlscussmg the relative merits of Murphree and vaponzatlon efficlencles Holland and McMahon[12] attempted to show that m the dlstlllatlon of multlcomponent murtures, condltlons could exist m which the values of Murphree efficIencles were zero and mfimty while vaponzation efficlencles had finite, bounded values Their statements were later questloned by Standart [ 191 ?Present address, Centro de Engenhana de Engenhana, Porto, Portugal Qmmwa, Faculdade Expenmental values of vaporlzatlon efficlencles were pubhshed by Gucalp[lO] and M&m ef al [16] for the dlstlllatlon of the ternary system n-hexanelmethylcyclopentane/benzene in an Oldershaw column, it was shown that average ternary vaporlzatlon efficiencies were m close agreement with binary values obtamed m the same column Arguments m favour of the vaporlzatlon efficiency concept were also put forward by Castells Pique et al [3], pomtmg out that Its experlmental determmatlon 1s easier, above all for columns not operatmg at total reflux, and by Ellis and Boyes [6] Advantages of the use of vaporlzatlon efficlencles m dlstiatlon calculations were referred to by Holland [ 111, Yamada and Holland[24] and Yamada et al 1251 It 1s the purpose of the present work to present a quantltatlve comparison between Murphree and vaporlzatlon efficlencles using published ternary dlstlllatlon data for the systems acetone/methanol/ethanol [8], acetone/benzene/chlorobenzene [8], benzeneltoluenelm-xylene[l81 and n-hexanelmethylcyclopentane/benzene [ 10,161 It IS important to emphasize that all the experlmental work was carried out m small laboratory columns m which the hquld m each plate could be consldered completely mixed VAPOUR-LIQUID RQUlLLBRIlJM DATA The calculation of plate efficlencles requires the knowledge of accurate vapour-hquld equlhbrlum data As for each ternary system limited experimental mformatlon IS normally available, It 1s common practice to adopt correlating equations using the experlmental vapour-hquld equdlbrlum pomts to determme the constants m the equations For this purpose a computer program usmg the descent method of Davldon[5] for the mnumlzatlon of the differences between experlmental and predicted vapour mole fractions was prepared MarguIes three suffix equatlons[l3] were used to correlate hquld phase actlvlty coefficients The vapour phase was consldered to be ideal Pure component vapour pressures were evaluated m A G 332 terms of the Antoine equations MEDINA wrltten as et ol ted m Table 3 together with the numerical values of root mean square devlatlons (r m s d ) for the mole fraction of each component, the bodmg point temperature and the total pressure B hzmp: = A - C,+T where pp IS the vapour pressure of component I (mm Hg), A,, B,, C, are the Antoine constants for component I and T IS the temperature (“C) Values of the Antoine constants used are presented in Table 1 Sources of ternary equlhbrmm data for the drfferent systems are hsted m Table 2 The system benzene/toluene/m-xylene can be considered as an Ideal one[18, 231 A summary of the fitted Margules constants IS presen- PtATE E%FIcIEW!IEs Computer programs were developed[l41 for the calculatlon of vapour phase plate efficlencles from expenmental hquld composltlons and temperatures Neither Nord [18] nor Free and Hutchlson[8] measured liquid plate temperatures and so, m the treatment of their results, the liquid in each plate was assumed to be a saturated Ilqud Table 1 Antome constants component A B C Acetone 7 1171 1210 595 229 664 Benzene 6 90565 1211 033 220 790 Chlorobenzene 6 9781 1431 a53 217 55 Ethanol 8 1122 1592 864 226 184 n-Hexane 6 8778 1171 530 224 366 MCP 6 8628 1186 059 226 042 Methanol 8 0810 1582 271 239 726 Toluene 6 9580 1346 773 219 693 m-Xylene 7 0065 1460 183 214 a27 TabIe 2 Vapour-hqmd eqmhbrmm data Author system Acetone/Methanol/Ethano~ Paxton Amer, Van Free n-Hexane/M Eelknap C P /Benzene and 1 Hutchxon 7 Wlnk1.e Acetone/Benzene/Chlorobenzene Benzene/Toluene/m-Xylene Reference and Ga-jewskl and 2. Weber and Westephely 9,23 Table 3 Correlanon of vapour-llqmd equtibnum Acetone system Methanol Ethanol <l)/ (2)/ (3) Acetone cl)/ n-Hexane Benzene <2)/ MCP Chlorobenzene (3) (I)/ (2)/ Benzene Margules M (1.2) 0 6334 0 4708 0 constants M (2,1> a 6283 0 2602 0 1695 M (1,3) a 5600 0 2456 0 1772 N (3,l) 0 3161 a 2530 0 2084 M (2,3) 0 0794 0 0125 0 00133 M (3,2) a470 -a la53 0 01578 RHSD -0 007 0 007 0 006 ye temp press 0 341 0 008 0 005 0 009 0 375 9 531 8 471 a Y2 YS (OC) (mm Hg) 1499 0 0 0 0 005 005 007 168 4 012 (3) 333 Murphree and vaporlzatlon efficrenctes m multlcomponent disttllation From the large number of results obtamed, those presented m Tables 47 were selected as typical examples for the systems benzeneltoluenelm-xylene, acetonelbenzenelchlorobenacetone/methanol/ethanol, zene and n-hexanelmethylcylcopentanelbenzene respectlvely Plots of expernnental composltlon protiles and calculated values of Murphree and vaponzation efficlencles for the first three systems are presented m Figs l-3 Sumlar plots for the system n-hexane/methylcyclopentane/benzene were pubhshed elsewhere [ 10,161 wrttten[l4] to allow the defimtion of the possible extremes of calculated values of Murphree efficiencies The followmg experimental errors were assumed Liquid composlhon Vapour-liquid 001 (mole fraction) error-0 005 (mole fraction) situations 1 of experrmental errors, sampling and analysis) errors, on calculated computer program was between Murphree efficiencies and vapormtion xylene efficlencles-system benzeneltoluenelm- Plate number x Component 0 E” EMV 926 0 058 2 10 11 were defined, as ERRORS ON CALCULATED EFFIclENcm In order to assess the influence hquld composltlon errors (due to and vapour-liquid eqmhbnum values of Murphree efficiencies, a Table 4 Companson eqmhbnum For any plate n two extreme follows Sttuatton INFLUENCE OF -AL. VALUES OF - error4 0 016 Benzene 0 906 0 0 322 0 Toluene 0 066 0 027 0 207 2 12 m-Xylene 0 028 0 005 0 512 3 52 Benzene 0 808 0 963 0 239 0 941 Toluene 0 071 0 030 0 122 2 21 m-Xylene 0 041 0 007 0 380 4 12 968 960 Benzene 0 868 0 957 0 224 0 928 Toluene 0 079 0 034 0 177 2 09 m-Xylene 0.053 0 009 0 272 4 58 912 Benzene 0 a50 0 952 0 176 0 Toluene 0 083 0 036 0 086 2 18 m-Xylene 0 067 0 012 0 253 4 59 Benzene 0 a35 0 947 0 134 0 a97 Toluene 0 089 0 040 0 121 2 11 m-Xylene 0 076 0 013 0 144 5 03 Benzene 0 814 0 940 0 166 0 888 Toluene 0 097 0 044 0 150 2 03 m-Xylene 0 089 0 016 0 178 4 76 Benzene 0 786 0 931 0 193 0 874 Toluene 0 104 0 048 0 126 2 01 m-Xylene 0 110 0 021 0 7.34 4 37 Benzene 0 664 0 891 0 537 0 882 Toluene 0 113 0 061 0 171 1 72 m-Xylene 0 223 0 048 0 647 2 28 Benzene 0 46s 0 792 0 609 0 839 Toluene 0 129 0 090 0 410 1 26 m-Xylene 0 406 0 iia 0 636 1 89 Benzene 0 252 0 596 0 619 0 780 Toluene 0 132 0 133 2 77 0 969 m-Xylene 0 616 0 0 608 1 50 271 334 A G MEDINA et al Table 5 Companson Plate between Murphree efficrencles and methanol/ethanol Component x vaporization efficlencres-system Y+ 6 Comparison Plate 2 7 " Acetone 0 420 Methanol 0 464 Ethanol 0 116 Acetone 0 351 0 495 0 481 0 Methanol 0 495 0 435 0 517 1 07 849 Ethanol 0 154 0 070 0 454 1 Acetone 0 262 0 419 0 566 0.837 Methanol 0 519 0 473 0 522 105 Ethanol 0 219 0 0 584 1 43 Acetone 0 201 0.356 0 393 0 Methanol 0 526 0 0 268 1 04 log 500 65 735 Ethanol 0 273 0 144 0 418 1 52 Acetone 0 135 0 272 0 481 0 738 Methanol 0 519 0 528 0 829 0 997 Ethanol 0 346 0 200 0 501 1 36 Acetone 0 073 0 170 0 637 0 793 Methanol 0 464 0 541 0 616 0 960 Ethanol 0 443 0 0.630 1 20 Acetone 0 0 117 0 361 0 625 "lethanol 0 4J_4 0 499 0 821 0 969 Ethanol 0 0 0 622 1 15 between Murphree 046 540 289 384 efficlencles and vapomatlon zenelchlorobenzene efficlencles-system acetone/ben- + Component x E Y number 1 E %V number Table acetouel- Acetone 0 Benzene 0 574 Chlorobenzene 0 022 YV E" 404 Acetone 0 263 0 491 0 620 0 Benzene 0 684 0 0 608 1 14 503 824 Chlorobenzene 0 053 0 006 0 664 3 47 Acetone 0 134 0 333 0 650 0 791 Benzene 0 750 0 650 0 660 1 05 Chlorobenzene 0 116 0 017 0 640 3 02 Acetone 0 062 0 199 0 526 0 Benzene 0 713 0 756 0 866 0 992 Chlorobenzene 0 225 0 045 0 607 2 55 Acetone 0 020 0 084 0 655 0 737 Benzene 0 570 0 795 0 637 0 898 Chlorobenzene 0 410 0 121 0 641 1 85 Acetone 0 008 0 041 0 362 0 486 Benzene 0 408 0 723 0 514 0 788 Chlorobenzene 0 0 236 0 500 1 74 Acetone 0 002 0 013 0 529 0 599 Benzene 0 212 0 520 0 636 0 785 Chlorobenzene 0 786 0 467 0 1 25 564 632 673 Murphree Table 7 Comparison Plate between and vaponzatlon Murphree efficiencies in multicomponent efficlencles and vaponzatton pentane (M C P )/benzene Component x distdlation efficlencles-system Y 2 3 4 5 6 11 12 13 14 15 CESVol 33 No fF E" n-Hexane 0 476 0 505 0 577 0 MCP 0 305 0 293 1 07 0 977 Benzene 0 219 0 204 0 126 1 07 n-Hexane 0 449 0 480 0 905 0 994 MCP 0 313 0 302 0 672 1 01 Benzene 0 238 0 220 0 988 1 00 570 977 n-Hexane 0 431 0 464 0 MCP 0 318 0 308 0 470 1 02 BelIZZ.%le 0 251 0 231 0 6011 1 04 !-l-HeXaIle 0 396 0 431 1 02 1 00 MCP 0 334 0 326 1 92 0 976 Benzene 0 270 0 246 0 778 1 07 n-Hexane 0 382 0 416 YCP 0 331 0 323 -0 359 1 B.XlZene 0 287 0 258 0 580 1 05 0 417 0 971 0 953 04 II-Hexane 0 353 0 392 0 744 0 974 MCP 0 346 0 343 5 61 0 964 1 05 Aenzene 10 n-hexanelmethylcyclo- =MV number 1 335 0 301 0 272 0 487 0 326 0 369 0 622 0 956 0 349 0 352 -0 933 0 982 0 325 0 294 0 770 1 02 0 282 0 324 1 05 1 00 0 357 0 363 -1 31 0 0 361 0 320 0 878 1 02 Il-HeXane 0 249 0 298 0 667 0 MCP 0 332 0 350 1 36 1 02 419 0 961 944 Benzene 0 369 1 17 0 977 n-Hexane 0 214 0 263 0 713 0 MCP 0 308 0 331 104 946 1 00 Benzene 0 478 0 411 0 876 1 02 n-HeXaTIe 0 178 0 231 0 674 0 925 MCP 0 279 0 315 0 807 0 970 BeKl2ene 0 0 467 0 850 1 02 988 543 I-l-HeXane 0 132 0 180 0 956 0 MCP 0 238 0 279 0 994 0 999 Benzene 0 630 0 525 0 831 1 03 879 n-Hexane 0 097 0 150 0 658 0 MCP 0 183 0 242 0 0 985 Ben2eIle 0 720 0 Z-l-HeXaIle 0 054 939 631 1 01 0 999 0 092 1 14 1 06 752 MCP 0 138 0 198 0 Benzene 0 808 0 716 0 952 1 n-Hexane 0 032 0 059 0 825 0 920 MCP 0 093 0 143 0 898 0 964 Benzene 0 0 787 0 766 1 03 875 0 925 00 A 336 G MEDINA et nl 50 45 40 35 30 5 g 25 OS 00 * 00 2 I 3 4 5 6 7 04 02 00 Plate nunbet Ag 1 Vanation of plate efficiency and composition with plate number-system benzene/toluene/m-xylene -, Murphree eff , --0, vaponzahon eff , 0, benzene, 0, toluene, +, m-xylene Fig 3 Variation of plate efficiency and composition with plate number-system acetone/benzene/chlorobenzene -, Murphree vaportzatron eff , q, acetone, 0, benzene, +, chlorobeneff ,-, zene where x,_, , and X, , are the mole fractions of component I m the lqutd entermg and leavmg plate n respectively and (K,, ,)1 and (K, ,)> are the vapour hquld eqmhbnum ratios for sltuatlons 1 and 2 For total reflux the equations defining vapour phase Murphree efficlencles for sltuatlons 1 and 2 can be wntten as (EM”” t)l = 0 002 Xn-14 - X”,, + w”,h(~“#)1-x,,--~ 00 - 06 - 04 - 02 - 0°0 I 2 x I 2 3 4 5 6 x"_,,~-x",,-ooo2 u%.ivn ‘12= W” Mxn J2 - x, 7 I + 0 004 The extreme values based on the assumed errors are plotted m Fig 4 for benzene (system n-hexanelmethylcyclopentanelbenzene) DISCUSSION OF RFSULTS of the calculated values of plate efficiencles allows the followmg comments to be made An 3 4 5 6 7 analysts Platellumber Fig 2 Vaflatlon of plate eficlency and composltlon with plate number-system acetone/methanol/ethanol -, Murphree eff , ---7 vaporlzauon eff , 0, acetone, 0, methanol, +, ethanol (a) Murphree eficrencres (I) Most of the calculated ties lie in the tnterval (0,l) values of Murphree efficlen- Murphree and vapowatlon efficiencies m multlcomponent 337 dlstdlation three sets of efficlencles, calculated vapour composltlons vary only slightly This 1s because the wide vacation m the efficiency values IS due to the low dependence of efficiency vapour composition on Conversely a well defined efficiency value results from the case where the vapour composition is heavdy dependent on efficiency The resultmg error m the computed vapour composltlon 1s naturally of the same size m both cases These results explain the observations of Cllianu et al [4] (b) Vaponzatton eficlencres (1) Vaponzatlon efficiencies are normally smaller than unity for the more volatile component (MVC) the concentration of which IS rncreasmg upwards and hm 00 0 I n 2 4 6 6 IO 12 14 (E,v,) = 1 (4) t 16 Flat6nunb6r Fig 4 Influence of experunental errors on Murphree efficienn-hexane~methylcyclopentane/benzene-component cies-system benzene -, Extreme situations 1 and 2, ---, expenmental values (u) The largest varmtions of Murphree efficiencies with composltlon occur for the intermediate component for which calculated values of Murphree efficiencies often fall outside this interval This is particularly evident for methylcyclopentane as, m this case, negative values appear together with very high positive values (m) The influence that expenmental errors have on calculated values of Murphree efficiencies may be enormous TIN is particularly important for the mtermediate component m the regon m wluch a maximum or a minimum of concentration occurs In fact the range of possible values can be mfimte when the difference appearmg m the denominator of Murphree’s definitions 1s smaller than the expenmental error (iv) Though the consideration of the possible range of experimental errors can lead to a wide range of values of Murphree efficiencies there IS often an interval of this range which lies between zero and one (v) Some negative values of efficiencies as well as some high positive values can be explamed by previous conslderatlons The above comments do not imply the non-existence of negative point efficiencies or of point efficiencies greater than umty Such situations can occur[ 15,21,22] and will be discussed later m detati[l5] The previous evidence shows the ddficulty m assigmng a specific numerical value to a Murphree efficiency m some circumstances and It raises the question of whether the error on the evaluation of Murphree efficiencies affects the determination of composltlon profiles Table 8 summarizes the results of the evaluation of the composItion of the vapour leavmg a plate (system n-hexane/methylcyclopentane/benzene-plate 6) using three different sets of efficiency, i&v, (EW)t, (Em)2 It can be seen that, in spite of the large differences between the (II) Vaporization efficiencies of the less volatile ponent (LVC) are normally greater than umty and hm 6% ,_vc) = 1 com- (5) xI_vc + 1 (m) Vaponzatlon efficiencies of the intermediate component are less than umty when the concentration of the component 1s increasing upwards and greater than unity when the concentration 1s decreasing In fact the vaporization efficiency 1s bound to be equal to unity whenever a maximum or mlmmum of concentration 1s reached (iv) For the less volatde component calculated values of vaponzation efficiencies spread over a wide range, typical examples occur for the systems benzeneltoluenelm-xylene and acetonejbenzenejchlorobenzene Table 9 shows the limits of vanation for these two systems and shows that the results of Ml&m et al [la] cannot be generalized (v) It 1s mterestmg to note that m a hypothetical column m which no separation occurs, that 1s to say plate composltlons are the same for plates 1 to N, vaporization efficlencles are dtierent from zero An example IS presented m Table 10 for acetone/benzene/chlorobenzene It IS clear that the range of possible values of vaponzatlon efficlencles say for the more volatile component 1s smaller than the interval (0, 1) and depends on the component mole fraction As the mole fraction of the more volatde component approaches unity the size of the interval of possible values of vaponzatlon efficiencies tends to zero Expenmental data obtamed by Nord[l8], Free and Hutchlsoni83 and Gucalp [lo] for the ternary systems benzene/toluenejm-xylene, acetone/methanol/ethanol, acetonelbenzenelchlorobenzene and n-hexanelmethyl- A G MEDINA ef al 338 Table 8 Iduence of experimental errors on piate to plate calculations zene-plate 6)* Murphree Component (system ir-hexane methylcyclopentane/ben- Predtcted vapour composltlon efflclency i-t-HeXZdne 0 744 0 382 M C P. 5 61 0 331 Benzene 0 487 0 287 0 381 n-Hexane 0 MCP 1 72 0 330 Benzene 0 355 0 289 n-Hexane MCP 0 613 0 380 -7 712 0 336 0 677 0 284 Benzene * Plate composltlon - xH 912 = 0 353, ‘Fable 9 Llmlts of variation component System Benzene Toluene m-Xylene Lower (l)/ (2)/ xM C p = 0 346, of vamzaticm 1 XB = 0 301 efficlencles Component 2 Component 3 UPPep 11m1t Lower llrnlt. 11m1t Upper llmlt 1un1t 1lrnl-t 0 780 0 960 0.969 2 21 1 50 5 03 0 486 0 824 0 785 1 14 1 25 3 47 LOWeP Upper (3) Acetone (l)/ Benzene <?I/ Chlorobenzene i Table 10 Vaporuation (3) efficlencles for a zero separation situation (system acetone/benzene/chlorobenzene) Plate Plate number composlt1on 1 2 3 Vaporization Component efflclencl0s 150 0 407 Acetone Benzene Chlorobenzene 0 002 0 212 0 786 1 685 Acetone Benzene Chlorobenzene 0 002 0 150 0 212 0 786 0 407 0 1 685 150 Acetone 0 002 0 Benzene Chlorobenzene 0 212 0 786 0 407 1 685 339 Murphree and vaponzatlon efficrenclesm multwomponent dlstdlatlon cyclopentane/benzene were used on a quantltatlve compamon between Murphree efficlencles and vaponzatlon efficiencies It was shown that (a) The vaponzatlon efficiency concept fads to descnbe the behavlour of the phases m a dlstflatlon plate due to its mathematical hmltatlons The pattern of calculated values of vaponzation efficlencles IS the same for all the systems as the vaponzatlon efficiency of the more volatile component IS normally less than umty, the vaporlzatlon efficiency of the less volatde component 1s normally greater than unity and the vapomation efficiency of the intermediate component takes values close to unity (b) A wide variation of the vaporlzatlon efficiency with composition can exist above all for the more volatde component (c) The range of possible values of vaponzatlon efficiencies IS limited and depends on the component mole fraction (d) Vaponzatron efficiencies differ from zero m sltuatlons m which no separation occurs (e) “Murphree type” efficiencies are m agreement with physical reality as their values normally belong to the interval (0,l) Values falling outside this interval can normally be Justtied in terms of the influence that experimental errors have on calculated Murphree efficlencles, alternatively such values hlghhght mterestmg physical situations (reverse diffusion, dtiuslon barriers) (f) The influence that experimental errors (hquld composttlon errors and vapour-hqmd eqmllbrmm errors) have on calculated values of Murphree efficlencles may be enormous This effect IS particularly Important for the intermediate component m the regon m which a maxlmum of concentration occurs (g) Although experimental errors seriously affect calculated values of Murphree efficlencles their influence on plate to plate cakulatlons IS llmlted Such mfluence 1s of the order of magnitude of the experlmental errors of the authors (AGM) wishes to thank Junta Naclonal de Inveshga@o Clentlfica e Tecnologlca-ComlssHo Invotan-Portugal for the award of a research scholarshlp Acknowledgements-One NOTATION A, B, C Ehnv E, K Antome constants Murphree vapour phase plate efficiency vaporlzatlon efficiency vapour-liquid eqmllbnum ratio P0 T x y Y* Subscripts n I vapour pressure temperature hquid mole fraction vapour mole fraction eqmhbnum vapour composition plate number component REFERENCES [l] Amer H H , Paxton R R and Van Wmkle M , Ind Eflgng Chem 1956 48 142 [2] Belknap R C and Weber J H , J Chem Engng Dara 1%16 485 [3] Castells Pique F , Bugarel R and Mora J C , Rev Inst Franc P&role 1974 29 849 [4] Czhanu S , Brauch V and Schlunder E U , Ver/ahrenstechnrck 1974 8 84 I51 Davidon W C , Report ANL 5990 (Reg) Argonne NatIonal Laboratory 1959 161 Elk S R M and Boyes A P , Trans Instn Chem Engrs 1974 52 202 [71 Free K W and Hutchlson H P , J Chem Engng Data 1959 4 193 H P , Int Symp hstrllatlon Bnghton, England 1960 [91 Gajewskl 2 , Koks, Smola, Gaz 1958 3 106 Umverslty, BlrIlO1 Gucalr, U , Ph D Thesis, Bummgham mm&am, England 1966 Prentuze Hall, 1111Holland C D , Multrcomponent D&&ztron Englewood CldTs, New Jersey 1963 r121 Holland C D and McMahon K S , Chem Engng Scr 1970 25 431 [13] McDermott C and Ellrs S R M , Chem Engng Sc# 1965 20 545 [14] Medma A G , Ph D Thesis, Bnmmgham Umversity, Bummgham, England 1976 [I51 Medma A G , McDermott C and Ashton N , in prepara tlon WI Mlskm L G , Ozalp U and Ellis S R M , Br Chem Engng F31Free K W and Hutchison Proc Tech 1972 17 153 P71 Murphree E V , Ind Engng Chem 1925 17 747 WI Nord M, Trans Am Instn Chem Engrs 1946 42 863 Cl91 Standart G , Chem Engng See 1971 26 985 DOI Taylor D L , M SC Thesis, Texas A & M Umverslty, USA 1962 WI Toor H L and Burchard J K , A ICh E J l%O 6 202 WI Vogelpohl A and Ceretto R ,Chem Ing Tech 1972 44 936 WI Westephely H , Chem Ing Tech 1970 42 1367 r241 Yamada I and Holland C D , Preprmts for PACHEC’72 of the Society of Chemical WI Yamada I, Matsumoto Japan 1973 6 68 Engmeers of Japan 1972 N and Suzuki M , J Chem Engng