Electrochemistry

advertisement

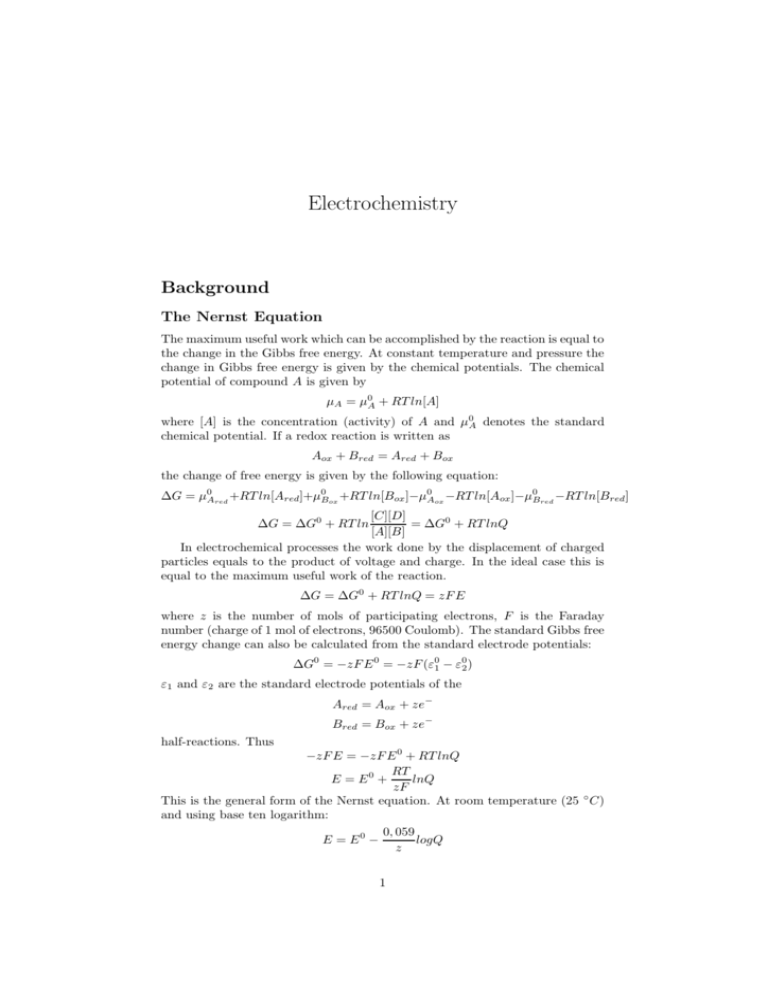

Electrochemistry Background The Nernst Equation The maximum useful work which can be accomplished by the reaction is equal to the change in the Gibbs free energy. At constant temperature and pressure the change in Gibbs free energy is given by the chemical potentials. The chemical potential of compound A is given by µA = µ0A + RT ln[A] where [A] is the concentration (activity) of A and µ0A denotes the standard chemical potential. If a redox reaction is written as Aox + Bred = Ared + Box the change of free energy is given by the following equation: ∆G = µ0Ared +RT ln[Ared]+µ0Box +RT ln[Box]−µ0Aox −RT ln[Aox]−µ0Bred −RT ln[Bred] [C][D] = ∆G0 + RT lnQ [A][B] In electrochemical processes the work done by the displacement of charged particles equals to the product of voltage and charge. In the ideal case this is equal to the maximum useful work of the reaction. ∆G = ∆G0 + RT ln ∆G = ∆G0 + RT lnQ = zF E where z is the number of mols of participating electrons, F is the Faraday number (charge of 1 mol of electrons, 96500 Coulomb). The standard Gibbs free energy change can also be calculated from the standard electrode potentials: ∆G0 = −zF E 0 = −zF (ε01 − ε02 ) ε1 and ε2 are the standard electrode potentials of the Ared = Aox + ze− Bred = Box + ze− half-reactions. Thus −zF E = −zF E 0 + RT lnQ RT lnQ E = E0 + zF This is the general form of the Nernst equation. At room temperature (25 ◦ C) and using base ten logarithm: 0, 059 logQ E = E0 − z 1 Conductivity of electrolytes The resistance R of a conductor is proportional to the length l and inversely proportional to the cross section q of the conductor. R=ρ l q The ρ coefficient is called specific resistance, 1/ρ is the specific conductivity (κ). Specific conductivity can be calculated from the molar specific conductivity (Λ, depends on the concentration) and concentration (c) of the component ions of the electrolyte. κ = Λ1 c1 + Λ2 c2 + ... Laboratory exercise Electroplating an iron sheet with zinc The electroplating of metals is generally carried out in order to improve the appearance or corrosion resistance of a surface by depositing a thin layer of some other metal on it. Protection of iron surfaces against corrosion is often carried out by zinc plating. Zinc plating protects the iron surface by insulating it from the environment (zinc itself corrodes much slower due to the continous oxide layer on its surface). Furthermore the Zn/Zn2+ system has a more negative electrode potential than the F e/F e2+ system, which provides a protection even when the coating is damaged (cathodic protection). Equipment and Matrials • iron sheet (cathode), 2 pieces of zinc (anode) • ZnCl2 · H2 O: Provides the initial zinc content of the electrolyte, contributes to the conductivity of the solution. • N H4 Cl: Increases the conductivity of the solution, complexates the zinc ions, increases microthrowing (more even surface), sets the pH. • large (500 ml) cristallization tank • two glass stands, wires, multimeter, potentiometer, power source Procedure The uniformity and proper adhesion of the plating requires thorough cleaning and degreasing. The steps of the cleaning process are the following: • mechanical cleaning (polishing) • alkaline cleaning (40% NaOH solution, 10 minutes, hot water bath) • rinsing with distilled water • solvent cleaning (aceton), drying 2 • etching, activating (10 % HCl, 5 minutes) • rinsing with distilled water Dry the iron sheet with a paper towel, measure the surface and mass. Dissolve 50g ZnCl2 · H2 O and 75g N H4 Cl in 500 ml distilled water. Assemble the setup shown on fig. 1. without closing the circuit. Pour the electrolyte in the cristallisation tank. Immerse the electrodes and close the circuit. With the help of the potentiometer set the current to the value corresponding to 1A/dm 2 current density. Deposition of the zinc layer lasts 30 minutes. After the 30 minutes lift the iron cathode out of the electrolyte and break the circuit. Rinse the plated iron sheet with distilled water, dry it and measure it’s mass. árammérõ A változtatható ellenállás − Zn Fe + áramforrás elektrolit Figure 1: Exercises • From the mass of the deposited zinc layer calculate the amount of charge used for the deposition (Faraday’s law). From the time of the process and the applied current calculate the efficiency of the electrolysis. • Assuming that the density of the deposited zinc is 7.1g/cm3 calculate the thickness of the zinc layer. Assembling a copper-zinc battery Chemical power sources convert the energy of the cell reaction directly to electric work. Primer batteries has irreversible cell reactions. Secondary batteries (rechargeable storage batteries) can be converted back to their original state with the help of a current flowing in the opposite direction. In fuel cells the oxidation of fuels like hydrocarbons or hydrogene provide the electrical power. Equipment and Matrials • copper sheet, zinc sheet 3 • 1M KN O3 solution • 1M CuSO4 solution • 1M ZnSO4 solution • filter paper Procedure Activate the surface of the copper and zinc sheets by immersing in 2M HCl. Rinse the sheets. Cut a rectangular piece of filter paper ( 2x5 cm). Deliver a drop of the CuSO4 solution and a drop of the ZnSO4 solution to the filter paper approx. 3 cm from each other. Place the metal sheets on the top of moistened places so that each metal contacts with the solution of it’s salt. Deliver a drop of the KN O3 solution between the metal pieces so that the wet areas overlap. Measure the electromotive force of the cell with the help of a multimeter. Cu CuSO4 KNO3 ZnSO4 Zn Figure 2: Exercises • Calculate the theoretical electromotive force of the assembled battery. ε0Cu/Cu2+ = +0.34V ε0Zn/Zn2+ = −0.76V • Assuming that the concentration of the zinc sulfate solution and the standard electrode potentials are accurate, calculate the concentration of the copper sulfate solution with the help of the measured electromotive force. • Assuming a 10cm electrode distance calculate the resistance of the cell. Λ[cm2 /molΩ] Cu2+ 80 Zn2+ 75 SO42+ 120 Molar specific conductivities at concentrations found in the cell: N O3− 52 K+ 50 H+ 300 Cl− 62 N H4+ 60 4