Success story of Kaba GmbH - Sternberg GmbH, Hohenstein

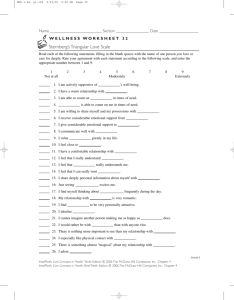

advertisement

Phone +49 7720 603-0 info@kbs.kaba.com www.kaba.com/workforce-management «Now, we no longer need to write everything down. We cannot do Success Story User Report of the Kaba GmbH Workforce Management Albertistr. 3 78056 Villingen-Schwenningen Germany Sternberg GmbH, Hohenstein-Ernstthal things more simply.» Wolfgang Naumann Technical director Sternberg GmbH, Hohenstein-Ernstthal www.sternberggmbh.de Kaba Partner: www.nowisys.de Everything is visible everywhere: The components produced in the Chem- Shop floor and machine data collec- nitz-Zwickau economic region are used tion creates transparency in energy generation, construction Sternberg is a leading manufacturer machines, the offshore sector, aviation worldwide of special screws, special and aerospace, ship diesel engine nuts, special turned parts, and other construction, and plant engineering. connection elements. The company with To ensure that it continues to grow in its 100 employees and 10 apprentices in the future, Sternberg required greater the heart of Saxony has a tradition transparency in its production division. stretching back one hundred years. The company thus decided in 2009 to Over this time, it has acquired a fine introduce a time and attendance and reputation as a manufacturer in particu- shop floor data collection system. The lar of special screws. For more than 100 shop floor data, machine data, quality years, Steinberg has ensured that reports and material bookings recorded engines run, cranes turn, and people can were to be integrated automatically in use the technology that they require. the ERP system. Employee working times were also to be recorded. Pictures courtesy of: Sternberg GmbH 10.2010 Sternberg GmbH, Hohenstein-Ernstthal Success Story The managers at Steinberg ultimately (good, scrap, post-processing), automat- opted for the company Nowisys IT-Serv- ic recognition of machine statuses ice GmbH from Chemnitz as their part- through digital or analogous inputs. ner for the SFDC/MDC area and for the Reasons for faults can be reported and overall integration. For Nowisys manag- automatically recorded quantities (good, ing director Ronald Wilhelm was easily scrap, post-processing) can be subse- able to put himself in the shoes of a ma- quently rebooked. The Sternberg chine operator or fitter and adapt the employee at the machine can therefore existing standard solution to the condi- call up all the information that he needs. tions at Steinberg accordingly. It is thus made possible for him to make “This practical relevance was very decisions quickly and autonomously if important for us,” emphasizes Wolfgang irregularities occur. Naumann, the technical director at These consistently record all warehouse Because only complete usage makes the Steinberg. In a first step, the personnel transactions with batches. At the fore- processes transparent, all workplaces in time and attendance and access control man workplaces, the foreman is always the production division at Sternberg system of the partner CompuTime kept up-to-date about the status in his have now been integrated into the sys- Ausweissysteme GmbH was introduced area of responsibility. He therefore tem. in April 2009. Since then, the Sternberg knows who is working on which job at “Now, we no longer need to write every- employees have been recording their which machine and what the specific thing down. We cannot do things more working times at Kaba terminals. processing status is. In addition, various simply,” says Wolfgang Naumann, enthu- To regulate access to the production analyses are available as help in the siastically. The machine data collection hall and to the office wing, several doors decision-making process. system simplifies and shortens the processes from ordering and storage of the were equipped with mechatronic CardLink components from Kaba. The solution is integrated into the material via production to administra- It was thus possible to save on wiring. existing ERP system. tion and sales. “The sales person sees Access is only permitted for persons In addition to the “normal” SFDC reports for himself what stage the processing of who identify themselves with their badg- (job sign-on/sign-off, set-up, processing, the job for his customer is at,” says the es as authorized. The next step involved quantity reports, etc.), additional func- managing director of the 100-plus-year- the production division. The solution tions are available to the employees at old company with satisfaction. “Every- h.Server, a middleware that combines the SFDC terminals. Managing director thing is visible everywhere.” Sternberg the various modules, and the SFDC hard- Wolfgang Naumann explains this as thus meets the requirements of all ware were installed and initially put into follows: “As a fundamental principle, audits, certifications and product liability operation at three pilot stations. At the we are pursuing the goal of providing as the manufacture, refining and testing end of 2009, the roll-out then began the production employee with all the of each product can now be monitored across all stations. At the beginning of information that can have a positive and documented seamlessly and without 2010, the shop floor and machine data influence on the process. Showing initia- great effort. It is thus detected immedi- collection system was fully operational. tive is explicitly requested!» ately when certain parameters cannot It consists of 13 SFDC stations with Kaba The same functional scope is available be complied with. “An auditor now sees multi-touch terminals, 13 MDC stations for the MDC terminals as for the SFDC straight away at our company that we with 13 Kaba terminals and a total of 35 terminals. Additional functions are made have superbly managed operations,” machine connections and 27 Bedanet possible by the Bedanet 90 80 machine says Wolfgang Naumann, with convic- 90 80 I/O modules, 6 foreman work- connection: counting of the numbers tion. places and 3 mobile devices. produced, classification of the numbers