NATEF Program Accreditation Standards

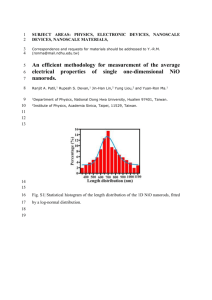

advertisement