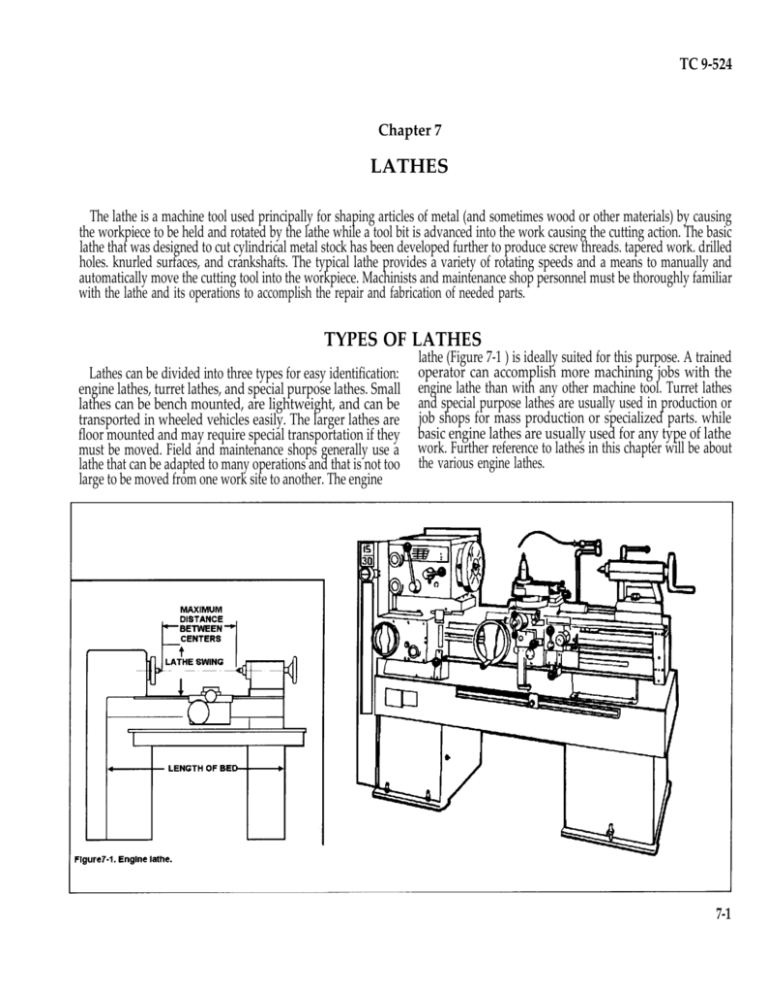

lathes types of lathes

advertisement