Machine Parameters & Correct Tooling

advertisement

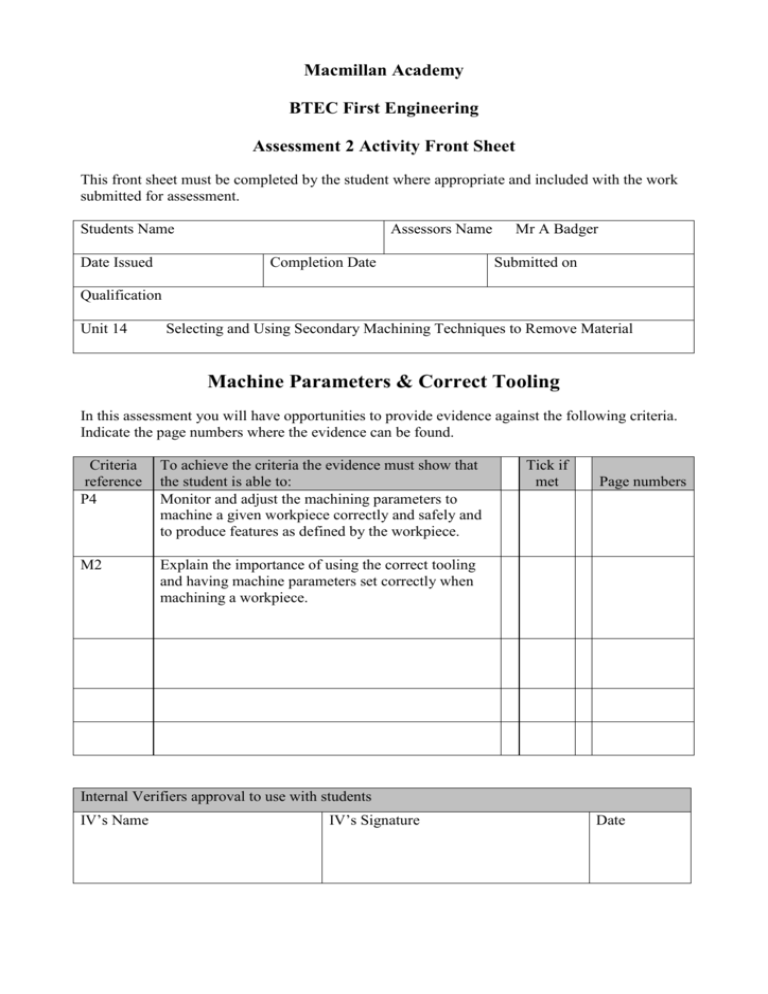

Macmillan Academy BTEC First Engineering Assessment 2 Activity Front Sheet This front sheet must be completed by the student where appropriate and included with the work submitted for assessment. Students Name Date Issued Assessors Name Completion Date Mr A Badger Submitted on Qualification Unit 14 Selecting and Using Secondary Machining Techniques to Remove Material Machine Parameters & Correct Tooling In this assessment you will have opportunities to provide evidence against the following criteria. Indicate the page numbers where the evidence can be found. Criteria reference P4 To achieve the criteria the evidence must show that the student is able to: Monitor and adjust the machining parameters to machine a given workpiece correctly and safely and to produce features as defined by the workpiece. M2 Explain the importance of using the correct tooling and having machine parameters set correctly when machining a workpiece. Tick if met Page numbers Internal Verifiers approval to use with students IV’s Name IV’s Signature Date Assessment Feedback Form Assessment Feedback Report Unit Title: Selecting and Using Secondary Machining Techniques to Remove Material Assignment Title: Machine Parameters & Correct Tooling Student’s Name: P4 M2 Assessment Criteria Monitor and adjust the machining parameters to machine a given work piece correctly and safely and to produce features as defined by the work piece. Achieved Explain the importance of using the correct tooling and having machine parameters set correctly when machining a work piece. Yes/No Evidence Comments/feedback Yes/No Yes/No Yes/No Yes/No Assessor’s Signature: Date Assessor’s General Comments: Internal Verifier’s Comments on Assessment Name Signature Date Student’s Comments: Student’s Signature: Date Macmillan Academy BTEC First Engineering Assessment 2 - Machine Parameters & Correct Tooling Scenario You are the engineering apprentice for a large industrial company. As part of your training you must undergo appreciation courses in the other trades. The following tasks form part of a mechanical fitter’s job description. Tasks 1 You need to find a picture of a micrometer (pg 86), explain its function and how to read it so that it can be used to monitor the machining process. You must also find a picture of the crossfeed handle on the lathe. This is the handle that feeds the cutting tool/post across the face of the work adjust (and makes the tool cut deeper into the side of the metal). You need to describe the measuring scale on the handle so that you can explain how to set the depth of cut. This will cover the marking criteria P4. 2 On this task you can use the information gathered in assignment 1 task 3, the lathe cutting tools (pg 98). You need to draw the four cutting tools, roughing, knife, finishing, parting, and describe how they are used on your plumb bob project. The next part of this task involves you drawing the correct tool position diagram (97) showing how the tool is set against the work being cut and what will happen if the cutter is in the wrong place. This will cover the marking criteria M2.