j o u r n a l o f m a t e r i a l s p r o c e s s i n g t e c h n o l o g y 2 0 9 ( 2 0 0 9 ) 3592–3596

journal homepage: www.elsevier.com/locate/jmatprotec

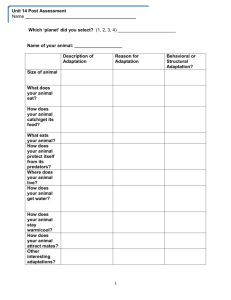

Adaptation for tandem cold mill models

Carlos Thadeu de Ávila Pires a , Henrique Cezar Ferreira b,∗ , Roberto Moura Sales b

a

Companhia Siderúrgica Paulista (Cosipa), Estrada de Piaçagüera, km. 6, CEP 11573-900, Cubatão SP, Brazil

University of São Paulo, Department of Telecommunication and Control Engineering, Av. Prof. Luciano Gualberto, trv. 3, n. 158, CEP

05508-900, São Paulo, SP, Brazil

b

a r t i c l e

i n f o

a b s t r a c t

Article history:

The ideal conditions for the operation of tandem cold mills are connected to a set of refer-

Received 18 March 2008

ences generated by models and used by dynamic regulators. Aiming at the optimization of

Received in revised form

the friction and yield stress coefficients an adaptation algorithm is proposed in this paper.

31 July 2008

Experimental results obtained from an industrial cold rolling mill are presented.

Accepted 25 August 2008

© 2008 Elsevier B.V. All rights reserved.

Keywords:

Cold rolling

Set-up model

Adaptation

Optimization

1.

Introduction

Physical models for rolling mills have been intensively developed in the last years, hoping to increase quality of steel

strip and productivity of rolling processes. Nevertheless, these

two characteristics are only achieved using models sufficiently

accurate. The availability of accurate models is associated to

set-up optimization and adaptation methods, and, in function of this, has been intensely explored in the literature.

Among optimization works, Pires et al. (2006) report good

results of quality and productivity after having applied a nonlinear simplex optimization method to set-up an industrial

cold mill; Wang et al. (2000) present the results of an investigation into an optimal scheduling for tandem cold mills based on

genetic algorithm; Sekiguchi et al. (1996) analyze set-up accuracy of low thickness reduction when using rougher rolls in an

industrial mill and Fiebig and Zander (1982) present interesting concepts of productivity applied to set-up of cold rolling

mills. At the same time, models will only be precise enough

∗

Corresponding author. Tel.: +55 11 3091 5273; fax: +55 11 3091 5718.

E-mail address: henrique@lac.usp.br (H.C. Ferreira).

0924-0136/$ – see front matter © 2008 Elsevier B.V. All rights reserved.

doi:10.1016/j.jmatprotec.2008.08.020

if equated with parameters representing the present status

of the rolling process. Among these parameters are the friction , between the strip and the rolls, and the yield stress

k of the strip. These coefficients cannot be measured with

the instrumentation available today and their effect on the

process are quite similar, making the question of accuracy

even more complex. In order to face this problem, different

adaptation schemes have been proposed in the literature.

Originally, Bryant (1973) pointed in his book, Automation of

Tandem Mills, the importance of such adaptation. Recently,

it has been the object of several works. Atack and Robinson

(1996) demonstrate how process models implemented with

adaptation schemes can predict, with accuracy, the load and

torque of flat wide strip rolling; Randall et al. (1997) describe

how a set-up model with adaptive scheme improved the head

and tail off-gage in a hot finishing mill; Nishino et al. (2000),

based on a physical model of a plate rolling process, present an

empirical and adaptive approach to improve the accuracy of

a rolling load prediction model; and finally, Wang et al. (2005)

j o u r n a l o f m a t e r i a l s p r o c e s s i n g t e c h n o l o g y 2 0 9 ( 2 0 0 9 ) 3592–3596

show how the accuracy of rolling force calculation in a tandem cold mill can be improved through the adaptation of strip

deformation resistance model.

In the present work, an adaptation scheme is proposed and

applied to a four stand tandem cold mill at Cosipa plant, Brazil.

Such scheme is based on the minimization of a cost function

which takes into consideration the contribution of the friction

coefficient and the yield stress coefficient.

For the minimization of the cost function, Nelder and Mead

(1965) simplex algorithm was employed. An objective function

is defined such that the main variable force is taken into consideration. Although more sophisticated model has recently

been proposed, for example, by Pawelski (2003), force, torque,

slip and power are calculated using a classical cold rolling

model developed by Bland and Ford (1948), because this is the

model employed in the automation system of the cold mill.

This paper is organized as follows: in Section 2, the

mechanical and electrical characteristics of the tandem cold

mill are introduced and the automation and control system architecture is described; in Section 3, the mathematical

model of the cold rolling mill process is presented and some

advantages of its use are summarized; in Section 4 details of

the adaptation algorithm and the cost function are presented;

simulation and experimental results are explained in Section

5; and finally, Section 6 presents the main conclusions.

2.

Cosipa four stand tandem cold mill

Cosipa cold mill is a coil to coil four high, four stand mill, in

which each stand is composed by two backup rolls and two

work rolls, the later coupled to dc motors controlled by digital speed regulators, totaling 16 MW of nominal power. Two

hydraulics actuators, installed at the top of the stands, complete the set of reduction of each stand. Table 1 presents the

main electrical and mechanical characteristics of the tandem

cold mill and the entry and exit dimensions of the processed

material, which consists of low, medium and high carbon steel

sheet.

Table 1 – Electrical and mechanical characteristics

Annual production (ton)

Maximum speed (m/min)

Work rolls diameter (mm)

Back up rolls diameter (mm)

1,248,000

1080

490–575

1270–1422

Motors

Stand

Power (kW)

Speed (rpm)

Voltage (V)

1

2 × 1800

433–1046

900

2

2 × 1800

433–1046

900

3

2 × 1800

433–1046

900

4

2 × 1482

200–485

700

Material

Carbon steel

Entry thickness (mm)

Exit thickness (mm)

Coil width (mm)

Coil internal diameter (mm)

Coil external diameter (mm)

2.00–4.75

0.38–3.00

650–1575

610

1930

3593

The automation architecture of Cosipa four stand tandem

cold mill includes the following four levels, as described by

Bolon (1996).

• Level 3 (Production planning level): This level is responsible

to decide which product will be produced and according to

which specification.

• Level 2 (Process optimization level): From entry and exit coil

data specifications, this level is responsible for finding the

best mill set-up in order to ensure high quality and productivity. Based on static models this level includes a set-up

optimization procedure (Pires et al., 2006) and an adaptive

loop which improves the set-up specification for every new

coil.

• Level 1 (Process dynamic control): According to the reference signals from level 2 and measured process signals,

suitable control signals are generated in this level for the

actuators. This level includes the dynamic model and the

mill master logic. In addition, it records the process variables necessary to the adaptive functions of level 2.

• Level 0 (Actuators and sensors): This level includes sensors,

motor drives and hydraulic actuators for gap control.

The present paper refers to the adaptation procedure of

level 2. More specifically, the coefficients and k are adapted

in order to optimize the predicted forces to be applied by the

mill stands.

3.

The rolling model

Bland and Ford (1948) cold mill model was chosen as the mathematical process model used in this paper to calculate the

rolling loads of the tandem cold mill. According to Bland and

Ford theory, the strip is subjected to three different zones in

the arc of contact between the strip and the work rolls. In the

first zone, located at the entry of this region, the strip is elastically compressed until the yield stress condition is achieved.

In the second zone, the strip is plastically deformed until a

minimum thickness while in the third and last zone, it suffers elastic recover. The mathematical development to find

the final expressions of force, torque and deformed roll radius

can be followed in Bland and Ford (1948). Hereafter, only the

final expressions of these dimensions will be shown.

The rolling force by unit width P is a nonlinear function

of the entry thickness hin , the exit thickness hout , the entry

tension in , the exit tension out , the entry yield stress kin ,

the exit yield stress kout , the coefficient of friction and the

deformed work roll radius R ,

P = fP (hin , hout , in , out , kin , kout , , R ).

(1)

The deformed roll radius is a function of the elastic and

plastic forces and can be calculated in the following manner,

R = R 1 +

16P(1 − R2 )

ER (hin − hout )

,

(2)

where R and ER are the Poisson’s ratio and the Young’s modulus for the work roll, respectively.

3594

j o u r n a l o f m a t e r i a l s p r o c e s s i n g t e c h n o l o g y 2 0 9 ( 2 0 0 9 ) 3592–3596

Finally, the yield stress is expressed by the following equation

kin(out) = k · [A + B εin(out) ] · {1 − C exp[−Dεin(out) ]},

h 0

εin = ln

,

hinh 0

εout = ln

,

hout

(3)

where A, B, C and D are material dependent constants and h0

is the strip thickness at entry of the mill, assumed to be the

thickness of annealed strip. Both of Eq. (1) and k of Eq. (3) are

initialized and adjusted in the adaptation phase.

4.

Adaptation procedure

This section is focused on the adaptation of the friction coefficients and yield stress k parameter, which are central for the

Bland and Ford rolling model. More specifically, before rolling

the first coil of a batch, estimates for these parameters are

adopted for the calculation of the reduction for each stand.

This calculation is performed through an optimization procedure, which is described in detail in Pires et al. (2006). Besides

the reduction for the stands, the optimization procedure generates predicted values for the rolling forces. After the rolling

of the first coil, these predicted values are compared to the

measured values and the parameters and k are then adapted,

aiming at improving the predictions of force for the second

coil. This section presents the proposed adaptation scheme,

which is the main contribution of this paper. In Section 5 some

experimental results are also presented.

The proposed adaptation scheme consists of two main

phases as shown in Fig. 1: in the first phase, using Bland and

Ford model and an initial guess for and k, predicted values

of forces and their corresponding reduction for each stand

are calculated. These calculated forces are compared to the

measured forces and, in the second phase, through an optimization algorithm, the parameters and k are adjusted in

order to minimize an objective function. The simplex nonlin-

Table 2 – Parameters of the adaptation cost function

Stand #

Kf

Nf

1

2

3

4

10

2

10

2

10

2

10

2

ear method, initially proposed in Nelder and Mead (1965) is

used in the optimization phase.

Some comments on the Bland and Ford model have already

been presented in Section 3. In what follows, a brief description of the Nelder and Mead simplex algorithm is presented.

Among the various existing optimization methods, some

recent applications related to cold mill set-up optimization include nonlinear programming (Ozsoy et al., 1992),

genetic algorithms (Wang et al., 2000), and more specifically

the (Nelder and Mead, 1965) simplex method, which was

employed in Fiebig and Zander (1982) and also by Cosipa cold

mill automation system (Pires et al., 2006). A detailed description of the simplex method can be found in Walters et al.

(1991).

Like for every optimization algorithm, the definition of the

objective function plays a central role for the Nelder and Mead

algorithm. In the present case, the adopted objective function

is given by

J=

4

i=1

(i)

Kf ·

(i)

(i)

Fcalc − Fmeas

(i)

Fmeas

Nf(i)

(4)

where the index i = 1, 2, 3 and 4 refers to each stand of the

(i)

(i)

mill; Fcalc and Fmeas are the calculated and measured forces,

respectively and Kf and Nf are constants adjusted according to

the values of Table 2.

The search for the parameters and k that minimize the

objective function is implemented in the Nelder and Mead

algorithm through the following steps:

(i) Set initial values for and k.

(ii) Introduce disturbances in and k and, for each new point,

calculate the corresponding objective function value.

Three main operations may be accomplished from step

(ii): reflection, contraction and expansion, as illustrated in

Fig. 2, for an example of two optimization variables. Yet for the

two dimensions case, the algorithm proceeds in the following

steps.

(1) Sorting: The iterative process is initiated sorting the points

xW , xN and xB for which the function has its maximum

value JW , the second maximum value JN , and the minimum

value JB , respectively.

(2) Reflection: The average point or centroid xc is determined

finding the average of all points xi , except xW (see Fig. 2).

From equation:

Fig. 1 – Adaptation scheme.

x = xC + b · (xC − xW ),

(5)

3595

j o u r n a l o f m a t e r i a l s p r o c e s s i n g t e c h n o l o g y 2 0 9 ( 2 0 0 9 ) 3592–3596

Table 3 – Force error for the actual and proposed

adaptation

Stand #

1

2

3

4

k

Fcalc

Fmeas

Error %

0.0283

1.34

1100

1112.7

−1.14

0.0288

1.34

972

977.3

−0.58

0.0241

1.34

841

832.1

1.07

0.0965

1.34

953

982.1

−2.96

k

F calc

Error %

0.0387

1.30

1113.2

0.05

0.0290

1.30

976.7

−0.60

0.0173

1.30

833.4

0.156

0.1104

1.30

982.5

0.041

Fig. 2 – Simplex algorithm steps.

and assuming the minimization step b = 1, it results x = xR ,

known as reflection of xW with respect to xC . If JB < JR < JN ,

then xW is replaced by xR and the process is restarted from

step 5.

(3) Expansion: If JR < JB < JN , then set b = 2 and get x = xE , known

as expansion of xR with respect to xC . If JE < JB , xW is

replaced by xE and a new process is restarted from step

5.

(4) Contraction: If JN < JR < JW , a contraction is made, generating

a vertex x = xU for which b = 1/2. If JB < JU < JN , xW is replaced

by xU and a new process is restarted from step 5; If JW < JR ,

a contraction with change in direction must be done, generating a vertex x = xT for which b = −1/2. If JT < JW , xW is

replaced by xT and a new process is restarted from step 5.

(5) Stop condition: Sort the points of the new simplex as xW , xN

and xB for which the function has its maximum value JW ,

the second maximum value JN , and the minimum value JB ,

respectively. If J(xW) − J(xB) < ε, then stop; otherwise, go to

step 2. The value of the first stop criterion ε was selected as

0.001 and proved sufficient to get accurate results with a

Fig. 3 – Results of the present rolling mill model.

Fig. 4 – Convergence of the adaptation cost function.

not too big number of iterations. As a second stop criterion,

the maximum number of iterations was adjusted to 200.

Finally, as a last guarantee of halting the whole iteration

process, a maximum computation time may be chosen.

5.

Main results

Set-up accuracy of the actual rolling mill model, working with

the original adaptation technic are shown in Fig. 3 for 300

coils processed in sequence. Intending to assess these results,

simulations using the proposed adaptation procedure were

performed and compared to the currently operating method

for a batch of coils.

The upper part of Table 3 shows the accuracy of the predicted rolling load for the adaptation scheme currently in

use in the tandem cold mill, while the lower part presents

the same characteristic for the proposed adaptation procedure. For comparison purpose, it was considered a batch of

10 dimensionally similar coils, not considering the first coil.

It can be noted a slight improvement in the mean force error

when the friction and yield stress coefficients, for the next coil,

are calculated using the proposed adaptation technic.

The adopted strategy was to adjust the step of the yield

stress coefficient greater than that of the friction coefficients,

taking into consideration that most part of the force error is

3596

j o u r n a l o f m a t e r i a l s p r o c e s s i n g t e c h n o l o g y 2 0 9 ( 2 0 0 9 ) 3592–3596

references

Fig. 5 – Comparison of force error.

certainly due to the steel strip hardness changes. To evaluate the convergence capacity of the method, the number of

steps of one of those adaptation set-up simulation is shown

in Fig. 4.

Considering the two methods, a comparison of the mean

error and error distribution, for each one of the mill stands,

can be shown in Fig. 5. In this figure, the first four distributions correspond to the present adaptation while the next

four to the simulated method. It can be noted a significant

improvement in the model accuracy when using the proposed

method.

6.

Conclusions

This work presents an adaptation procedure for the set-up

generation of a four stand tandem cold rolling mill, located

at Cosipa plant, Brazil. The proposed algorithm consists of

an objective function, which takes into consideration friction and yield stress coefficients and is minimized using

Nelder and Mead (1965) simplex method. Simulation results

show that the methods adopted is robust, very fast and

can be tuned very easily leading to results according to the

expected for the industrial tandem cold mill into consideration.

Atack, P.A., Robinson, I.S., 1996. Adaptation of hot mill process

models. Metallurgical Plant and Technology 60, 535–542.

Bland, D.R., Ford, H., 1948. The calculation of roll force and torque

in cold strip rolling with tensions. Proceedings of the

Institution of Mechanical Engineering 159, 144–153.

Bolon, P.L., 1996. Corum Tandem Cold Mill Setup Model: Cosipa

Implementation. Davy-Clecim, Cergy Le-Haut, 1996.

Bryant, G.F., 1973. Automation of Tandem Mills. The Iron and

Steel Institute, London.

Fiebig, E., Zander, H., 1982. Automation of tandem cold rolling

mills. Metallurgical Plant and Technology 3, 88–97.

Nelder, J.A., Mead, R., 1965. A simplex method for function

minimization. Computer Journal 7, 308–313.

Nishino, S., Narazaki, H., Kitamura, A., Morimoto, Y., Ohe, K.,

2000. An adaptive approach to improve the accuracy of a

rolling load prediction model for a plate rolling process. ISIJ

International 40, 1216–1222.

Ozsoy, I.C., Ruddle, G.E., Crawley, A.F., 1992. Optimum scheduling

of a hot rolling process by nonlinear programming. Canadian

Metallurgical Quartely 31, 217–224.

Pawelski, H., 2003. An analytical model for dependence of force

and forward slip on speed in cold rolling. Steel Research 74 (5),

293–299.

Pires, C.T.A., Ferreira, H.C., Sales, R.M., Silva, M.A., 2006. Set-up

optimization for tandem cold mills: a case study. Journal of

Materials Processing Technology 173, 368–375.

Randall, A., Kaplan, J.F., Mislay, J.S., Oprisu, G.J., 1997. Adaptive

finishing mill setup model and gage control upgrade for LTV

steel Cleveland works 80-in. hot strip mill. Iron and Steel

Engineer 8, 31–40.

Sekiguchi, K., Seki, Y., Okitani, N., Fukuda, M., Critchley, S., Habib,

W.G., Hartman, D., Shaw, K., 1996. The advanced set-up and

control system for dofasco’s tandem cold mill. IEEE

Transactions on Industry Applications 32, 608–616.

Walters, F.H., Parker, L.R., Morgan, S.L., 1991. Sequential Simplex

Optimization. CRC Press, Boca Raton.

Wang, D.D., Tieu, A.K., de Boer, F.G., Ma, B., Yuen, W.Y.D., 2000.

Toward a heuristic optimum design of rolling schedules for

tandem cold rolling mills. Engineering Applications of

Artificial Intelligence 13, 397–406.

Wang, J.S., Jiang, Z.Y., Tieu, A.K., Liu, X.H., Wang, G.D., 2005.

Adaptive calculation of deformation resistance model of

online process control in tandem cold mill. Journal of

Materials Processing Technology 162/163, 585–590.