APPLICATION NOTE

Transmission Sampling Techniques – Theory and Applications

FTIR sampling by transmission is a very popular method for

collection of infrared spectra. Its use is easy to explain – the

methods are intuitive and do not require sophisticated sampling

accessories. In many cases, the sample can be placed directly into

the path of the infrared beam (with the help of sample holder) and

scanned. Further benefits of transmission sampling techniques

include compatibility with automated sampling and microsampling

techniques such as IR Microscopy.

Transmission techniques are well documented and have been

successfully used for many years. A large number of spectral

libraries contain transmission spectra and are often used as

references for the purpose of qualitative analysis. Transmission

techniques offer many advantages and should be used whenever

possible, unless reliable sample preparation becomes too difficult,

too time consuming or impossible. Transmission is also widely

used for quantitative applications, as significant numbers of basic

measurements adhere to the Beer-Lambert law. The law provides

a mathematical relationship between the infrared radiation

absorbed by the sample and the sample concentration:

Sample Preparation and Analysis

A=a•b•c

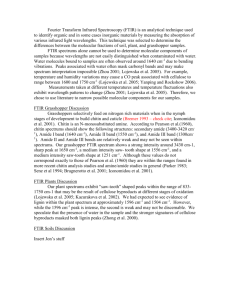

FTIR Spectrum of 1 drop of Extra Virgin Olive Oil pressed between

25 mm KBr windows and held in the IR beam using the PIKE Universal

Sample Holder.

Where:

A = absorbance

a = absorptivity

b = pathlength

c = sample concentration

The Beer-Lambert law states that absorbance is linearly

proportional to sample concentration (with sample pathlength

and absorptivity constant). The actual measurements are generated

in percent transmittance (which is not a linear function of concentration), however, they can be converted in real time to

absorbance by all modern FTIR instrumentation. As mentioned

before, transmission measurements are intuitive and simple.

However, the majority of samples are too thick to be measured

directly and they have to be processed in some way before

meaningful data can be collected. Some of the sample preparation

techniques are time consuming and can be destructive. Liquids

and pastes are generally the easiest samples to run. A large

number of liquid cells and windows are available for liquid measurements. Solid samples (with the exception of thin films) require

sample preparation – making a pellet (typically potassium bromide –

KBr) or a mull. Gas samples require a suitable gas cell with a

pathlength sufficient to detect the desired component.

Liquids

Most liquids and dissolved solids are easy to measure by transmission.

Viscous liquids or pastes can be simply pressed between 2 IR

transparent windows and measured by FTIR.

Thin liquids or samples in solvent may be best run by using a

demountable liquid cell or a sealed cell, consisting of two windows

with a precision spacer in-between. One of the windows has two

drilled holes for the introduction and evacuation of the sample.

A large number of cell options are available – these include

permanently sealed cells and demountable cells with different

window materials and a wide selection of spacers.

The pathlength of liquid cells can be easily measured with

your FTIR spectrometer. Just place the empty cell into the FTIR

and collect its spectrum. The frequency of the sine wave spectrum

(produced by back reflection within the cell) provides the

pathlength using the following equation;

P = (10 • N) / (2 • Δ cm-1)

Where:

P = pathlength of cell in mm

N = number of fringes within Δ cm-1

Δ cm-1 = wavenumber range of fringe count

It is very important to select compatible IR transparent windows

for your liquid samples. Please refer to the chart on the last page

of this note to select your windows. If you still have questions,

please call us.

Solids

The easiest to analyze are film and polymer samples less than

200 micrometers thick (ideal thickness for the major component

of a polymer film is about 20 microns). These samples can be

simply placed into a sample holder and immediately scanned.

However, the majority of solid materials must be prepared

before their infrared spectra can be collected. In many cases

sample preparation involves grinding of the sample and mixing it

with an IR transparent material such as KBr and then pressing a

pellet. While this method of solids analysis is time consuming, it

produces an excellent result.

Polymer Film from Product Packaging Material – held in place with

the PIKE Universal Sample Holder. Polymer is identified as Atactic

Polypropylene and the film is determined to be 27.1 microns thick.

FTIR Spectrum of Caffeine prepared as a 13 mm KBr Pellet and held in

position with the PIKE Sampling Card.

The thickness of the polymer film can be calculated from the

fringe pattern in the spectrum using the following equation;

T = (10000 • N) / (2 • n • Δ cm-1)

Where:

T = thickness of polymer film in microns

N = number of fringes within Δ cm-1

Δ cm-1 = wavenumber range of fringe count

n = refractive index of polymer

The same procedure can be used for samples which can be

sliced and pressed to an appropriate thickness – especially for IR

microsampling.

For IR microsampling, one can place a small sliced sample

into a sample compression cell and apply pressure to hold the

sample and to thin it to a useable thickness – as shown in the

following spectral data.

Solid Sample Preparation Tips

The best method for preparation of solid samples involves mixing

the sample (about 5% by weight) with an IR transparent material

(typically KBr) and pressing a pellet. The mixing is best done with

the ShakIR accessory which produces a fully mixed and pulverized

sample in about 30 seconds. The mixing can also be done with a

mortar and pestle – but not as well. Generation of a pellet involves

pressing the prepared mixture with a hydraulic or hand press into

a hard disk. The pellet, ideally 0.5 to 1 mm thick is then placed in

a transmission holder and scanned. Typically, the pellet technique

provides good quality spectra with a wide spectral range and no

interfering absorbance bands.

Samples which do not grind well and/or are affected by

solvents and mulling agents can be analyzed with high pressure

techniques. Typical samples include fibers and paint chips. The

accessory used for such applications utilizes two diamond anvils.

Difficult samples are placed between the diamonds and crushed,

compressed and flattened to the thickness necessary to obtain

good quality FTIR spectra. Diamond cells are transparent to IR

radiation except in the region of 2400 cm-1 to 1700 cm-1. The high

pressure diamond cells require the use of a beam condenser or

an infrared microscope.

Micro Spectrum of a Layered Polymer using a PIKE µMAX IR Microscope

and Compression Cell with KBr windows.

FTIR Spectrum of Methanol Vapor measured with the PIKE 100 mm gas

cell using 0.50 cm-1 spectral resolution.

An alternate method for analysis of solid materials involves

making a mull. Mulls are sample suspensions in Nujol (refined

mineral oil) or Fluorolube (perfluorohydrocarbon). The process

is based upon mixing 1 to 2 drops of the mulling agent with a

ground sample until a uniform paste is formed. The paste is

transferred onto a KBr or other IR transparent disk, placed in

the sample compartment of the spectrometer and scanned. The

advantage of this technique is that it is a relatively quick and

simple procedure; disadvantages include interference from

mulling agent absorption bands. (Both Nujol and Fluorolube have

characteristic spectral features and in most cases have to be used

as a pair in order to generate a complete mid IR spectrum. Nujol

is used below 1330 cm-1, Fluorolube above 1330 cm-1).

Simple demountable cells (50 mm to 100 mm) are recommended for samples in a 1 – 10% by weight concentration range.

For highly dilute samples (ppm to ppb concentrations), longpath cells are required. The long-path cell reflects the IR beam

several times through the sample using a set of mirrors positioned

on the opposite ends of the cell, producing a pathlength to 10 to

30 meters – or more. It is important to select window materials

compatible with the investigated sample. Gas sampling accessories

can be fitted with different windows to accommodate the physical

and chemical characteristics of the measured gas. Special designs

for high pressure and temperature controlled experiments are

also available.

Gases

Transmission sampling by FTIR provides an excellent means for

sample identification and quantification of sample components.

Most samples measured by transmission techniques require

some sample preparation, however, the quality of the results

and amenability to automation and microsampling offer

significant advantages.

Summary

Analysis of gas samples is a unique form of transmission sampling

by FTIR as the identified sample does not need to be of pure

composition. At high spectral resolution, most gas mixtures can

be identified and quantified since absorbance bands can be

selected within the spectrum, which are resolved and distinct

from other components within the sample.

Properties of Select Infrared Transmitting Materials For Transmission Spectroscopy

SWL cm-1

LWL cm-1

RI

Solubility g/100 g

Hardness kg/mm2

MP °C

pH Range

11000

593

2.50

0.00

170

370

1–9

Material

Comments

AMTIR

GeAsSe glass, brittle

BaF2

Barium Fluoride

66600

691

1.45

0.17

82

1280

5–8

CaF2

Calcium Fluoride

79500

896

1.40

0.0017

158

1360

5–8

CsI

Cesium Iodide, very hygroscopic,

Somewhat Toxic

42000

172

1.73

44

20

621

NA

Diamond

Type IIa, strong IR absorbance

between 2700-1800 cm-1, costly

30000

<2

2.40

0.00

5700

550

flash point

1 – 14

Ge

Germanium, brittle, becomes

opaque at elevated temperatures

5500

432

4.00

0.00

780

936

1 – 14

KBr

Potassium Bromide, most widely

used for mid-IR applications

48800

345

1.52

53

6

730

NA

KRS-5

Thallium Bromide/Thallium

Iodide, Extremely Toxic!

17900

204

2.37

0.05

40

414

5–8

NaCl

Sodium Chloride

52600

457

1.49

36

18

801

NA

Polyethylene

For Far-IR, swells with

some organic solvents

625

<4

1.52

0.00

110

1.5 – 14

SiO2

Silicon Dioxide

50000

2315

1.53

0.00

460

1713

1 – 14

Si

Silicon, strong IR absorbance

between 624-590 cm-1

8900

624, 30

3.41

0.00

1150

1420

1 – 12

ZnS

Zinc Sulfide

17000

690

2.20

0.00

240

1830

5–9

ZnSe

Zinc Selenide

15000

461

2.40

0.00

120

1526

5–9

Notes: The above table is meant to be a general guide – brief and concise. For more information about these materials, consult appropriate reference books and

Material Safety Data Sheets (MSDS).

SWL – Shortest wavelength for transmission, 1 mm, 50% transmission

LWL – Longest wavelength for transmission, 1 mm, 50% transmission

RI – Refractive Index, at relevant wavelength

MP – Melting point

6125 Cottonwood Drive Madison, WI 53719 • (608) 274-2721 • (608) 274-0103 (FAX) • www.piketech.com • sales@piketech.com (E-MAIL)

©2011 PIKE Technologies. All rights reserved. All trademarks are the property of PIKE Technologies.