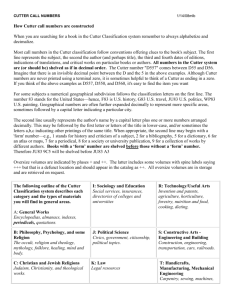

Catalogue

advertisement