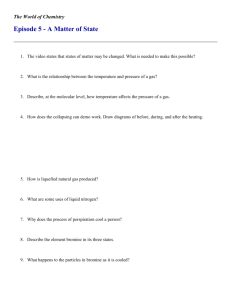

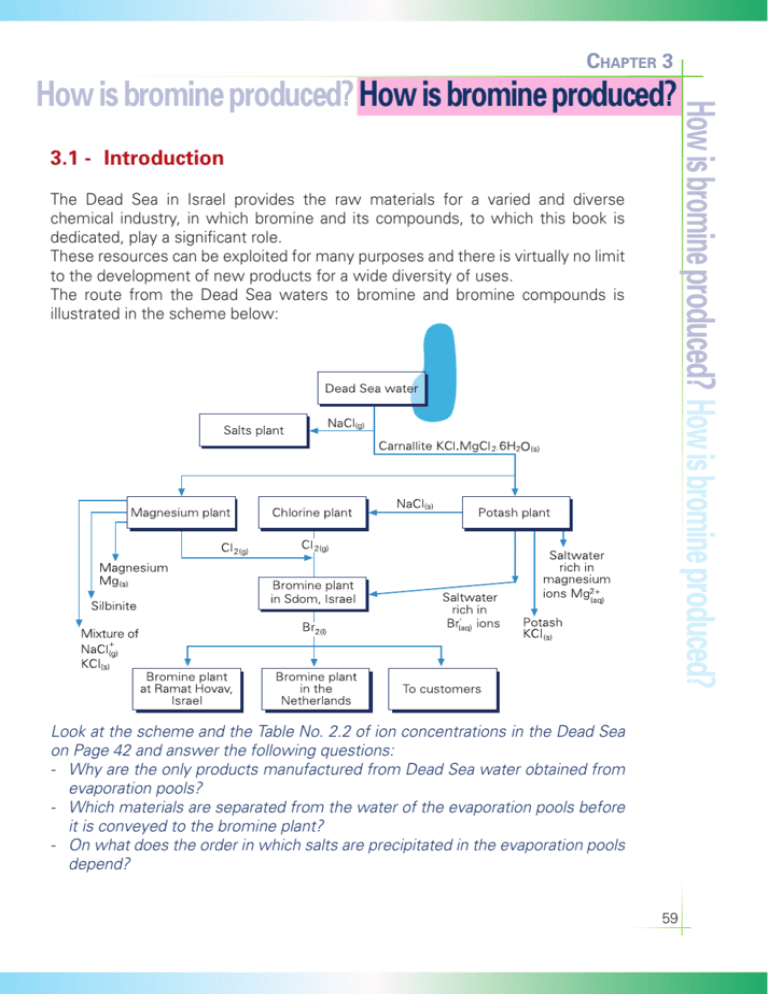

How is bromine produced?

advertisement