controldesign.com

Despite differences in their approaches

to problem-solving, older and younger

engineers begin to appreciate each

others’ skill sets and methods

CONTROLLER

ROOTS

Look to the OS for

Performance Upgrades

Improving

MOTOR

EFFICIENCY

PANEL

BUILDER

MARCH 2014

Best Pracices

CD1403_Cover.indd 1

3/11/14 4:43 PM

CD1403_FPA.indd 2

3/7/14 1:21 PM

Meetthefamily

OurPCBTrayswelcome

ANYapplication

The newest members of Phoenix

Contact’s family of PCB Trays satisfy

a wider number of applications. These

new trays were developed to address

specific environmental conditions by

integrating optional covers or fully

enclosed trays with an IP65 rating.

The design of these Phoenix Contact

PCB Trays gives you the flexibility of

mounting on a DIN rail, directly on

machinery or directly on the back of

your cabinet wall.

• UM-Proprofile – contains extruded

polyamide for high device-operating

temperatures of up to 100°C

• UM-ALUprofile – features

aluminum extrusion, which delivers

high-temperature performance and

EMC shielding for noisy environments

• HC-ALUprofile – designed for

either handheld or panel-mount

applications, offering reliable, highheat operation, the same effective

EMC shielding and an IP65 rating

Meet the whole family!

Call 1-800-322-3225 or download

a copy of our PCB Tray brochure

and request free samples at:

www.phoenixcontact.com/pcbtrays

© 2014 PHOENIX CONTACT

CD1403_FPA.indd 3

3/7/14 1:23 PM

CD1403_FPA.indd 4

3/7/14 1:24 PM

CONTENTS

Volume 18, No. 3

FEATURES

32

COVER STORY

Work in Harmony

Despite Differences in Their Approach, Older and Younger

Engineers Begin to Appreciate Each Others’ Skill Sets

Sarah Cechowski, associate digital editor

40

MOTOR CONTROLS

The Roots of Controllers

Some Users Reorganize or Replace RTOS and Kernels in Their

Operating Systems to Gain New Manufacturing Capabilities

Jim Montague, executive editor

46

PRODUCT ROUNDUP

Pass It On

Moving Sensor Data to All Corners of the Business Means

Suppliers Offer More Connectivity Options, Compact Sizes

and Ease of Use

CONTROL DESIGN EXCLUSIVE

55

PROSOFT TECHNOLOGY

Media Converter Puts Ethernet

on Blue Hose

CONTROL DESIGN, (ISSN: 1094-3366) is published 12 times a year by Putman Media, 1501 E. Woodfield Rd., Suite 400N, Schaumburg,

Illinois 60173. (Phone 630/467-1300; Fax 630/467-1124.) Periodical postage paid at Schaumburg, IL, and at additional mailing offices.

Address all correspondence to Editorial and Executive Offices, same address. Printed in the United States. ©Putman Media 2014. All rights

reserved. The contents of this publication may not be reproduced in whole or part without consent of the copyright owner. POSTMASTER:

Send address changes to Control Design, Post Office Box 3430, Northbrook, Illinois 60065-3430. SUBSCRIPTIONS: To apply for a free

subscription, fill in the form at www.ControlDesign.com/subscribemag. To non-qualified subscribers in the Unites States and its possessions,

subscriptions are $96.00 per year. Single copies are $15. International subscriptions are accepted at $200 (Airmail only.) Putman Media also

publishes CHEMICAL PROCESSING, CONTROL, FOOD PROCESSING, INDUSTRIAL NETWORKING, PHARMACEUTICAL MANUFACTURING and PLANT SERVICES. CONTROL DESIGN assumes no responsibility for validity of claims in items reported. Canada Post International

Publications Mail Product Sales Agreement No. 40028661. Canadian Mail Distributor information: World Distribution Services, Inc., Station

A, PO Box 54, Windsor, Ontario, Canada N9A 6J5. Printed in the United States.

March 2014 Control Design

CD1403_05_07_TOC.indd 5

5

3/11/14 6:05 PM

FEB14 A&C Ad (CM)_Layout 1 1/9/14 3:15 PM Page 1

Great Minds

Need Great Products

Allied Has What You Need in Automation and Control

1.800.433.5700

© Allied Electronics, Inc 2014. ‘Allied Electronics’ and the Allied Electronics logo are trademarks of Allied Electronics, Inc.

CD1403_FPA.indd 6

An Electrocomponents Company.

3/7/14 1:24 PM

CONTENTS

Volume 18, No. 3

COLUMNS

58 OEM Insight

9 Editor’s Page

Another ‘What’s in a Name?’

Question

Technology Tipping Point?

Joe Feeley, editor in chief

TJ McDermott, project manager, Systems Interface

13 Start Button

Undergrad Prep for Future Jobs

Sarah Cechowski, digital editor

HOT BUTTONS

19 OEM Spotlight

Involvement + Quality = Innovation

17 Live Wire

PLC’s Days Numbered?

24 InDiscrete

Hannover Fair Preview,

Siemens’ Big Truck and More

Jim Montague, executive editor

21 Embedded Intelligence

50 Real Answers

Looking for Panel-Build

Best Practices

The Union Solution

Jeremy Pollard, CET

54 Resources

Safe HMI Operation

45 TechFlash

Motor Efficiency and More

Hank Hogan, contributing editor

56 Product Showcase

Position. Click. Done.

Your conveyor is sensing.

SEE A DEMO AT:

CD201403.indd 1

CD1403_05_07_TOC.indd 7

Simply easy!

02/18/2014 8:49:02 AM

3/11/14 6:05 PM

" I get what I need to keep my line

running, when I need it.

It's great to be an engineer."

Your one-stop source for

INDUSTRIAL

ELECTRONICS

For Industrial Automation and Control, we have the products

& solutions you need from the most trusted brands.

newark.com | 800.463.9275

Newark_Omron_E5CC_Control

CD1403_FPA.indd

8

Design.indd 1

Featured product:

Digital Temperature Controller

(05W3874)

1/28/14

3/7/14 1:24

2:12 PM

PM

Joe Feeley

In Memory of Julie Cappelletti-Lange,

Vice President 1984-2012

•

editor in chief

•

jfeeley@putman.net

editor’s page

Technology Tipping Point?

1501 E. Woodfield Rd., Suite 400N

Schaumburg, Illinois 60173

630/467-1300

Fax: 630/467-1124

We regularly report about

Progress, and Prosperity in a Time of

the way industrial robots have

Brilliant Technologies by MIT Sloan

editorial team

grown to become a frequent addi-

professor Erik Brynjolfsson and

tion to automated and semi-auto-

research scientist Andrew McAfee.

mated machine operations.

“Self-driving cars are exciting, but

editor in chief

Joseph Feeley

jfeeley@putman.net

executive editor

Jim montague

jmontague@putman.net

managing editor

nanCy bartels

nbartels@putman.net

managing editor, digital media

Katherine bonFante

kbonfante@putman.net

associate editor, digital media

sarah CeChowsKi

scechowski@putman.net

senior technical editor

Dan hebert

dhebert@putman.net

contributing editor

hanK hogan

hank@hankhogan.com

In February, Dan Hebert wrote

about the use of machine vision in

The authors call themselves

that raise the performance bar for

mindful optimists. “If we under-

many end-user manufacturers.

stand the problems that we’re fac-

Late last year, we noted a report

facing, and take the right actions, I

Markets that predicts a global CAGR

think we could have a really, really

near 7% into 2016 for industrial ro-

good outcome,” Brynjolfsson said in

bots in the heavy machinery sector.

a recent interview.

And I told you about my introduction to Rethink Robotics’ Baxter,

the two-arm, somewhat-humanacting robot that’s aimed at doing

lower-skill, repetitive factory jobs,

design/production

ing and the opportunities that we’re

from analysts at Research and

lori golDberg

lgoldberg@putman.net

Jeremy pollarD

jpollard@tsuonline.com

long-haul truckers work?” they ask.

conjunction with industrial robots

editorial assistant

columnist

where will all the taxi drivers and

at Automate2013.

I try not to get too entangled in

“Self-driving cars are

exciting, but where will

all the taxi drivers and

long-haul truckers work?”

But at the same time, he recogniz-

the man vs. robot/technology/auto-

es it’s not automatic and will depend

mation debate that boils over, more

on our choices and the policies we

anetta gauthier

assoc. art director

angela labate

often now. Part of my trouble with

have in terms of education, fostering

it is when do you start the debate

entrepreneurship and tax policy.

subscriptions

clock. The Cotton Gin? The first

customer service

automatic dishwasher?

senior production manager

888/644-1803

circulation

audited may 2013

Air & Gas Compressors

921

Engineering & Systems

Integration Services

7,746

Engines & Turbines

1,649

Food Products Machinery

2,145

Industrial Fans, Blowers

& Air Purification Equipment

794

Industrial Heating, Refrigeration

& Air Conditioning Equipment

1,465

Industrial Process Furnaces & Ovens

806

Machine Tools

3,874

Materials Handling, Conveyors

& Conveying Equipment

1,882

Metalworking Machinery

3,537

Mining Machinery & Equipment

627

Oil & Gas Field Machinery & Equipment 1,213

Packaging Machinery

951

Paper Industries Machinery

352

Printing Trades Machinery & Equipment 510

Pumps & Pumping Equipment

785

Rolling Mill Machinery & Equipment

157

Semiconductor Manufacturing

Machinery

1,403

Textile Machinery

232

Woodworking Machinery

275

Other Industries & Special Industrial

Machinery & Equipment NEC

8,696

total

40,020

Where is the point at which the

the idea that there is more wealth,

massive and virtually immeasurable

as seen in steady, long-term GDP

benefits of technology are negated

growth in the U.S. “Spread,” they

by its harmful effects on individu-

say, is the idea of the “one percent.”

als, economies and societies?

Wealth is accruing unevenly, with

For a long time, automation and

the rich getting steadily—and

technology were hand-in-glove in a

sometimes fantastically—richer,

growing, widely beneficial society.

and the poor and middle class

Economies grew, as did the labor

struggling to maintain or improve

force and a strong middle class. For

their standard of living.

reasons other than just the effect

The book also explores Pigou-

of automation and technology, that

vian taxes, which assign costs to

outlook is in serious jeopardy.

negative externalities such as pol-

So the tipping point is when

lution and negative income taxes,

automation and technology and

by which individuals with little

robots wipe out too many jobs for

or no income receive money from

an economy’s own good. Is that a

the government.

non-recoverable tipping point?

I mention this because there’s

a new addition to the discussion

with The Second Machine Age: Work,

controldesign.com

CD1403_09_EDITOR.indd 9

The authors examine two

economic phenomena: “Bounty” is

March 2014 Control Design

9

3/11/14 4:46 PM

THE PULSE OF AUTOMATION

World’s Largest Selection of Ultrasonic Sensors

A product of world-class acoustic engineering

expertise, Pepperl+Fuchs ultrasonic sensors are

completely unaffected by dust, color variations,

gloss, or transparency.

With sub-millimeter precision, software

configurability, and detection ranges from

½ inch to over 30 feet, ultrasonics are ideal for

both switch-point and analog control of

objects as diverse as bottles, refuse containers,

wooden pallets, steel coils, and foods.

Download four

application reports

that show you how to

easily use ultrasonic

technology.

www.sensing.net/pulse

Scan. Learn More.

Pepperl+Fuchs, Inc.

330.486.0001

www.pepperl-fuchs.us

CD1403_FPA.indd 10

3/7/14 1:24 PM

Retroreflective

Photoelectric

Sensors

The usual way of detecting objects of various shapes

or heights has been through the use of an array of

single-beam photoelectric sensors or a thru-beam light

grid using two separate housings. This method can’t

precisely sense an object’s leading edge, especially

when the leading edge is indistinct. For example,

various types of pallets, parts ejected from a die,

stacks of newspapers, and cartons of varying heights,

widths, or shapes, can all provide indefinite leading

edges making part detection erratic.

Retroreflective sensors are now replacing these

older methods. This type of sensor uses multiple

transmitter beams and multiple receiver elements in

a single sensor housing to produce continuous height

detection. The sensor housing mounts opposite a

reflector. Without an object present, light from the

transmitters in the sensor housing travels to the

reflector where it bounces back to the receivers

housed with the transmitters. The simple press of a

pushbutton initiates a teach mode in the sensor that

lets it learn what conditions signify that no target is

present. Conditions change when an object enters the

sensing area between the sensor and the reflector,

triggering the sensor output.

Unlike an array of single-beam sensors that have

conical light patterns with a small diameter,

retroreflective sensors have a rectangular pattern of

light with a continuous height. This makes it possible

to detect the same-size object consistently throughout

the entire sensing area. Moreover, the sensor can

detect an object’s true leading edge even if the object

has no defined shape or position.

Retroreflective area sensors use only a single housing

together with a reflector. This brings material and

installation costs well below those of thru-beam light

grids or a comparable array of single-beam sensors.

Operationally, they are mechanically and electrically

the same as a single beam device.

Now you have a choice:

There or Where

Distance-based photo sensors address more challenging

applications by not just determining if an object is

THERE, but also WHERE it is located. Three methods

have emerged as front runners to show you Where:

n

n

n

Background Suppression

Multi-Pixel Array

Pulse Ranging Technology

Download our e-book that explains how

these technologies will work for you.

www.sensing.net/where

Scan. Learn More.

Distance-based photo sensors will have your standard

photo sensor nervously looking over its shoulder.

Pepperl+Fuchs (www.pepperl-fuchs.us)

Pepperl+Fuchs, Inc. • 330.486.0001 • www.pepperl-fuchs.us

CD1403_FPA.indd 11

3/7/14 1:25 PM

Start

measuring in

seconds.

2-line display

for easy adjustment

More features and

pre-programmed for

100mm to 1000mm

range right out of

the box.

Analog and digital outputs

4-20 mA or 0-10 Vdc

NPN/PNP user configurable

The Banner L-GAGE® LE550

Laser Measurement Sensor is the

low-cost, easy-to-use solution for

demanding measurement applications.

100mm

1000mm

LE550

Laser Sensor

Class 2 laser

visible spot for easy alignment

• Adjustable range from 100mm to

1000mm in 1mm increments

• Advanced imager technology senses a

wider range of materials and surfaces

from metal to black rubber

• Independent digital and analog outputs

Articulated quick disconnect

• Simple pushbutton adjustments

Customers First

Integrity Always

Quality in Everything

New Solutions – Every Day

1-888-373-6767 | bannerengineering.com

LE550 Laser Sensor

© 2014 Banner Engineering Corp., Mpls, MN USA

BA-2242

02.0314.0212

L-GAGE LE Ad_CD.indd 1

CD1403_FPA.indd

2/19/14

AM

3/7/14 10:47

1:25 PM

Sarah Cechowski

•

scechowski@putman.net

START BUTTON

Undergrad Prep for Future Jobs

It waS about this time three years ago when the

development. Koh interned for GE in Summer 2010 and

panic began to sink in. Spring commencement was just

2011, and for Intel during Summer 2012. In August 2012—

around the corner. My peers—and my parents—were

his senior year—Koh accepted a job offer from GE.

asking, “What do you have lined up after graduation?”

Brian Wallden, process engineer for blade-assembly

After four or more years at school, the whole point is to

operations for consumer product manufacturer, Proctor

have a job lined up—but that’s not as easy as it sounds.

& Gamble (P&G, www.pg.com) in Boston, landed his job

I was proud to say that upon graduating I would be

using a similar process. While obtaining his bachelor’s

leaving for Nashville, Tenn., to do a dual internship at an

degree in mechanical engineering from Penn State,

artist management company and an independent record

Wallden used job boards such as LinkedIn and Monster,

label. It was a temporary distraction from fear of the real

but found more promising opportunities via Penn State’s

world, which entailed submitting a million applications

online job-posting system, eCareer, where he could up-

to a job board black hole and competing with thousands

load his resume and cover letter for full-time positions,

of other people who had the same experience I did.

internships, co-op jobs and international opportunities.

Now, there are pre- and post-graduate career opportunities out there that students who secured a job

before graduating, or found one shortly after, will tell

you to take advantage of in order to gain the experience

employers look for in new hires.

Whether it is an internship, co-op program, network-

There are pre- and post-graduate career

opportunities out there to give you the

experience employers look for in new hires.

Wallden did four co-op tours before graduating. The

ing event, career resource center or simply guidance

first two were with multinational engineering and

from your educators, there is an abundance of ways to

electronics firm Robert Bosch (www.bosch.us), Charles-

help prepare yourself for what’s to come after you finish

ton, S.C., in the manufacturing division. The third was

your college degree.

with DuPont (www.dupont.com), Richmond, Va., in the

Brandon Cary, industrial designer for digital part mate-

research and development division. The fourth, in his

rialization company ExOne (www.exone.com) describes

senior year, was again with Robert Bosch, this time in

his job search as “hectic.” Upon graduating in May 2012

Stuttgart, Germany, in the research and development de-

from the Art Institute of Pittsburgh with his bachelor’s

partment. On his return to the U.S., Wallden interviewed

degree in industrial design, Cary used job boards such

with P&G and received a job offer a few days after.

as LinkedIn and Coroflot, a job site specifically for design

jobs, to apply for more than 200 positions.

He gave himself a deadline: After six months he’d

Doing multiple internships rewarded Andy Milluzzi,

research assistant at the National Science Foundation’s

(NSF) Center for High-Performance Reconfigurable

take any job he was offered. Luckily, right before that

Computing (CHREC, www.chrec.org) at the University of

six-month mark hit, he connected with ExOne through

Florida (UF), with several job prospects.

a friend who helped him get an interview and shortly

thereafter receive an offer.

It’s all about expanding your network, says Allen Koh,

Prior to graduating in 2012 from Rose-Hulman Institute of Technology with a bachelor’s degree in computer

engineering and software engineering, Milluzzi did a

part of the Edison Engineering Development Program

two-year internship with National Instruments (NI,

(EEDP) at General Electric Power & Water (GE, www.

www.ni.com) writing software for the NI CompactRIO

ge-energy.com). By challenging yourself to meet people

that serves as the robot brain used by FIRST Robotics

outside of your classroom and outside of work, you give

Competition (www.usfirst.org). He also worked as a pro-

yourself the opportunity to develop better networking

gram manager intern for Microsoft (www.microsoft.com),

skills, he says. Be proactive when looking for communi-

working on the Xbox gaming system. He also was a soft-

ties to join within and even outside your major, and find

ware development intern for Workflow (www.workflow.

extra curricular activities to get involved in.

com), software development intern for Hyland Software

Koh graduated in May 2013 from Olin College of

(www.hyland.com) and a robotic vision system intern

Engineering with his bachelor’s degree in electrical and

for Rose-Hulman Ventures (www.rhventures.org), an on-

computer engineering. As an undergraduate, Koh took

campus internship program with big-name companies.

advantage of Olin’s post-graduate planning (PGP) career

services to get some guidance on resume and cover letter

controldesign.com

CD1403_13_14_STARTBUTTON.indd 13

Milluzzi was offered a job from Microsoft shortly after

his internship, but declined to attend UF for graduate

March 2014 Control Design

13

3/13/14 12:29 PM

START BUTTON

school to pursue his long-term goal

Kolisetty, user-experience engineer

electrical and computer engineering,

of becoming a professor. To become

for Ford (www.ford.com), is following.

Kolisetty interned with Tesla Motors

a professor, one must know how

Kolisetty works on connectivity

(www.teslamotors.com), Fremont,

research and academia work apart

between personal devices, such

Calif. While this internship was

from having industry experience, he

as the iPhone and iPad, and Ford

beneficial for experience, her most

says. “My philosophy for getting a job

vehicles.

positive influence came from the So-

is to have fun.”

And that’s just the path Aiswarya

Prior to graduating from Olin in

ciety of Women Engineers National

May 2013 with a bachelor’s degree in

Conference, to which she was introduced by Olin’s PGP career center.

After attending the conference, Ford

Rugged Precision

The MAQ®20 Industrial

Data Acquisition & Control System

put her in touch with managers and

supervisors looking to fill new graduate positions.

Kolisetty’s position at Ford

focuses on product development.

Following a user-centric design

approach, her team develops

features that are engaging and

favorable to the customer.

CHREC’s Milluzzi went on to earn

his M.S. in electrical and computer

engineering from UF and is currently pursuing his doctorate, while

working for NSF’s CHREC. As a

project leader, Milluzzi looks at heterogeneous computing systems for

high-performance applications, also

known as “super computing.”

Wallden recently joined the P&G

team doing Gillette Fusion blade assembly operations. His role involves

design improvements, safety and

quality enhancements, better productivity and cost reduction through

mechanical process efficiency.

Signal Integrity, Compact Design

2 Software Packages for DAQ or T&M

GE’s Koh remains in his first year

of the two-year rotational program

EEDP. His current role focuses on

engineering design for wind turbine

• $17 per Channel Possible –

Lowest Cost in Industry

pitch and electrical controls. Koh is

also pursuing his master’s degree in

• Up to 384 Channels in 19”

Instrumentation Rack

electrical and computer engineering

at Georgia Tech.

• Application Software from $250

As an industrial designer, ExOne’s

• ±0.035% Accuracy

Cary reviews part files for customers

• 1500Vrms Channel-to-Bus

Isolation

them for application. He works one-

(industrial and art) and processes

on-one with customers and often

• PID Software Control

- Up to 32 Loops with ReDAQ® Shape

- Unlimited Loops with IPEmotion

• –40°C to +85°C Operating

Temperature

CD1403_13_14_STARTBUTTON.indd 14

needs to teach art process to them so

their engineers have a better idea of

how to design for their own process.

Instrument Class® Signal Solutions

dataforth.com • 800-444-7644

3/13/14 12:29 PM

TRUE STORY

When an overhead crane accidentally dropped a

steel pipe 15 feet onto an IceStation, workers were

relieved to find the pipe had not been damaged.

What was less surprising was the fact that the IceStation - along with the computer and monitor inside it

remained completely unharmed. All ITSENCLOSURES are constructed out of 14-gauge steel and built to last

forever and a day. Should one of our enclosures ever actually fail due to manufacturer defect, we will replace it

as fast as humanly possible so your business does not skip a beat. Built to meet NEMA 12 standards, IceStation

TITAN protects computer systems from harmful dust, dirt, and splashing fluids. With a large viewing window

designed to accommodate up to 24” wide screen monitors, a retractable keyboard drawer, oversized work

surface, and a track record of 29 years of experience protecting electronics, ITSENCLOSURES is the one name

you can trust. To learn more about IceStation TITAN, call 1.800.423.9911 or visit ITSENCLOSURES.com.

25

ITS14_TITAN_7.875x10.5.indd 1

CD1403_FPA.indd 15

2/19/14 10:05 AM

3/7/14 1:25 PM

More power for decentralized motion control.

Room for new

possibilities

Room for new

More power for decentral motion control.

` Motor-mounted ACOPOSmotor servo drives –

Machine modularity in motion.

` Significant space savings in the control cabinet

` Power classes from 500W to 4kW

` Fully integrated safety technology for SIL3

based on openSAFETY: STO, SOS, SS1, SS2, SLS,

SMS, SLI and SDI

` Maximum system productivity: One solution covers

CNC, robotics and motion control

Perfection in Automation

www.br-automation.com

CD1403_FPA.indd 16

3/7/14 1:25 PM

Jim Montague

•

executive editor

•

jmontague@putman.net

LIVEWIRE

PLC’s Days Numbered?

“Mr. Bond, they have a saying in Chicago: ‘Once is

November. However, it’s also been collaborating

happenstance. Twice is coincidence. The third time, it’s ene-

with 3S on using CoDeSys 3.5 PLC software, and the

my action.’ ”—Auric Goldfinger in Ian Fleming’s Goldfinger.

two will soon launch their Sitara AM5x processors,

I’ve always enjoyed this quote from James Bond’s

arch villain, but I never thought I’d experience it directly. Let me explain.

As you might know, I call or email dozens of sources

which will integrate two ARM Cortex-A15 cores.

The CoDeSys runtime software is operating as an

application on top of a Linux 3.8.13 real-time kernel,

and its subsequent PLC application contains a two-axis

for interviews. However, sometimes people call me,

motor-control system that’s using CoDeSys Softmotion

asking to talk about a variety of topics, usually how

module and an embedded EtherCAT master to drive two

terrific their product is. But, I was surprised when in

off-the-shelf EtherCAT servomotors. “Having motors and

the space of one week in February, I was asked to take

communications on the same device allows drives to

calls from three different semiconductor manufactur-

talk to higher-level motion functions, gives users a new

ers about how their chips could perform many of the

architecture for connecting motors, and means better

same functions as PLCs and their supporting Ethernet

intelligence, diagnostics and performance,” explains

networks. Of course, microprocessors have served

Thomas Leyner, TI’s system applications engineer.

inside industrial components for many years, but now

So what’s really going on here? Well, these an-

it appears that the chipmakers are taking a more direct

nouncements could simply coincide with last

role and are less content to labor away in obscurity

month’s Embedded World or last fall’s SPS/IPC/Drives

inside someone else’s modules.

tradeshows, or be linked to other easily explainable

First, Intel’s Internet of Things (IoT) Solutions

Group (ISG) told me about its Industrial Solutions

events. However, I think this might be just what they

want us to think.

System Consolidation Series embedded virtualization product that allows OEMs, machine builders and

system integrators to merge and manage multiple

discrete systems into one machine. Set to launch in

2Q14, this solution consists of an embedded computer

“ Machines with IP addresses and Ethernet

links to PC-based controls may simply

eliminate the need for PLCs altogether.”

with an Intel Core i7 processor and a pre-integrated

virtualization software stack, including Wind River’s

I believe the PLC’s number might be up. Just as

Hypervisor preconfigured to support three parti-

pneumatics were replaced by relays and relays by

tions running two instances of Wind River VxWorks

PLCs, I think microprocessors and their software

for real-time applications, and one instance of Wind

simply are continuing their march onto the plant floor,

River Linux 5.0 for non-real-time applications. Tim

trampling traditional hardware, and reaching the

Appleton, Intel ISG’s industrial marketing manager,

point that PLCs in many applications are going to be

reports that combining operating system (OS), hyper-

irrelevant and unnecessary quite soon.

visor, HMI and security functions will make it easier

In fact, unrelated to the news from Intel, Vitesse

for builders to construct and run virtual machine

and TI, several recent interviewees pointed out that

functions, and that its OS can serve as a home for

machines and equipment with Internet protocol (IP)

software-based PLC applications.

addresses and Ethernet networking can report to and

Second, Uday Mudoi, Vitesse Semiconductor’s

be controlled by upper-level PCs, and may eliminate the

product marketing VP, reported that his company

need for PLCs altogether. I know this isn’t news to some

will soon release its SimpliPHY processors, VSC8501

people, but it can still be a shock when that other shoe

single and VSC8502 dual, which are designed to make

falls, and a longstanding part of your industry dries up.

it easier and use less energy to run synchronous, se-

Personally, I’m hoping that another rule begins to

cure, gigabit Ethernet networking tasks and IoT func-

take effect; namely, as soon as someone writes an

tions. A third processor, VSC8514 quad Cu PHYsrsis,

epitaph for a technology, it immediately experiences

will run on other types of copper wiring.

a renaissance. So PLCs may continue to grow among

Third, Texas Instruments (TI) added its recently

a huge installed base that’s still moving from older

integrated motor control, position feedback and

controls and manual manufacturing methods. Or

the top five fieldbus communication protocols on

those applications could leapfrog right to Internet-

its Sitara AM4x processors, which it launched last

enabled, virtual PC-based control. Eek.

controldesign.com

CD1403_17_LIVEWIRE.indd 17

March 2014 Control Design

17

3/11/14 4:48 PM

Flowing with great possibilities.

Proline Promass 100

Compact without compromise

Proline

simply clever

As a direct, digital Coriolis flowmeter, the

Promass 100 opens entirely new perspectives

• Compact design without limitation of functionality

• Simultaneous measurement of mass or volume

flow, corrected volume, density, temperature and

viscosity (Promass I)

• Seamless integration into process control and asset

management systems via HART®, PROFIBUS® DP,

EtherNet/IP™ or Modbus RS485

• Modern webserver technology provides fast onsite

device configuration without additional software

• Industry optimized sensors for each application

NEW Heartbeat

Technology™

Endress+Hauser, Inc

2350 Endress Place

Greenwood, IN 46143

info@us.endress.com

www.us.endress.com

CD1403_FPA.indd 18

• Heartbeat Technology™ - monitor your process via

continuous diagnostics, multi-parameter monitoring and

onboard verification for maximum process reliability

www.us.endress.com/promass-100

Sales: 888-ENDRESS

Service: 800-642-8737

Fax:

317-535-8498

3/7/14 1:26 PM

OEM SPOTLIGHT

Involvement + Quality = Innovation

Ehrhardt Combines User Input, Experience and Quality to Create Flexible

Machines for Manufacturing Appliances, HVAC Units and Other Products

VARIETY MIGHT BE the spice

of life, but delivering it can be a

headache. So if you need flexible

machines that can make all kinds

of new products and parts, it’s viEHRHARDT TOOL & MACHINE

tal to have an experienced builder

that can provide all the innovations and quality you need.

“Our first job is to get our customers involved up-front and keep

them involved in the design process, so we’ll build a machine that

does precisely what it’s intended to

do,” says John Deibert, special ma-

OFF THE STACK

chines business segment manager

A vertical pallet destacker is the fi rst of fi ve machines in Ehrhardt Tool &

Machine’s Furnace Cabinet line, which its customers use to build enclosures for

residential and commercial furnaces.

at Ehrhardt Tool & Machine (www.

ehrhardttool.com) in Granite City,

Ill., just outside St. Louis. “This

the early 1990s, Ehrhardt began

it’s inexpensive,” Deibert adds.

process is more important now

adding automation and controls to

“We’re also doing remote diag-

because markets are demanding

its machines and sought to bridge

nostics on critical equipment.

changes in the design, look and

its mechanical and electronic

Customers grant us access to their

capabilities of many appliances,

systems. “We wanted to be a one-

VPNs to monitor and adjust ma-

HVAC units and furnaces. So

stop shop for automation, controls

chines, but we’re also looking at

instead of building a machine that

and interfaces,” Deibert says. “So

some Internet-based solutions.”

produces one parts family for a

as part of the engineering group,

furnace cabinet, our users need

I did the mechanics, Dave did the

ers, Dave King, Ehrhardt’s senior

machines that can make more

controls, and our philosophy was

controls engineer, adds that

sizes and types of parts.”

to combine them by taking an ap-

Ehrhardt’s other driving force is

proach from the top on down. For-

quality and delivering a low cost

bles and tests tool and die, auto-

tunately, we had talented people

of ownership to its users. “People

mated equipment and customized

and a team that could provide

might spend a bit more up-front,

machines, mainly for users who

what customers needed, and we’ve

but they’ll spend a lot less on a

need to punch, bend, form, weld

been doing it for 20 years.”

quality machine in the long run,”

Ehrhardt designs, builds, assem-

and braze sheet metal. Most of its

Deibert reports that Ehrhardt’s

Besides involving custom-

King says. “Now our machines can

equipment is used to manufacture

machines and production lines

handle more patterns and make it

commercial and residential HVAC

use PLCs, PACs and HMIs from

easier for operators to enter data

condenser units, heat exchangers,

Rockwell Automation, Mitsubishi,

because our controls use more

furnace cabinets and consumer

Omron, Schneider Electric and

tag-based, portable software.

appliances, such as washers, dry-

GE Intelligent Platforms. These

This means operators can adjust

ers, ovens, stoves and cooktops.

components and its machines are

recipes via on-screen fields for

It also builds leak-testing vessels

typically networked with EtherNet/

different parameters, which is

and heat-exchange cells for forced-

IP. For its load and testing equip-

simpler than typing in code. This

air residential furnaces.

ment, Ehrhardt uses PC-based

is a lot like having reusable func-

controls and LabVIEW software

tion blocks or a software library,

from National Instruments.

which is more flexible than having

Started by Willis Ehrhardt in

1937, the company operated during

World War II and for decades after

as a classic tool and die shop. In

controldesign.com

CD1403_19_OEMSPOTLIGHT.indd 19

“EtherNet/IP is simple and easy

for our users to understand, and

to input a one-off ladder program

for each machine.”

March 2014 Control Design

19

3/11/14 4:51 PM

©2014 Siemens Industry, Inc.

Request a

TIA Portal

Trial License

Scalability between all controller

families and a single engineering

environment generates significant

engineering efficiencies.

usa.siemens.com/plc-cd

SIMATIC Modular Controllers offer

performance, functionality, and value

along the entire production life cycle

for increased engineering efficiency

and reduced costs.

Siemens has redefined

engineering with its TIA Portal

software – a single engineering

framework that allows you to

combine PLC, PC-based control,

HMI, Network configuration,

Drives, and Safety in one

engineering environment.

Performance

• Low-end for discrete and standalone automation

• Mid-range for Factory Automation

• High-end for Factory &

Process Automation

Functionality

• Easy-to-use and program for

reduced downtime

• Modular expansion and scalability

for increased flexibility

• Global libraries for reuse of code

across complete PLC portfolio for

reduced development time and

increased configuration flexibility

• Integrated safety, security, and

diagnostics for increased productivity

Value

• Long-term compatibility and

availability for seamless migration

into future technologies

• Global network offering sales,

service, parts, training, and support

• Operating within our Totally

Integrated Automation (TIA) Portal,

our solution can improve your ROI up

to 30% through increased productivity

and reduced costs

Answers for industry.

CD1403_FPA.indd 20

3/7/14 1:26 PM

jeremy Pollard, CeT

•

jpollard@tsuonline.com

embedded intelligence

The Union Solution

So when will unions actually get it? Did that get

your attention?

Numbers don’t lie, do they? We’re in tough times,

My bride and I were on holiday when Canada 3000

went bankrupt. Passengers were left stranded and had

to pay for return flights from wherever they were. Not

but I believe that unions hold the key. I know it

sure about the refunds, but the reason given was that

sounds odd. Consider that since 1955, when the AFL-

the airline wasn’t making enough money. Really?

CIO was born, manufacturing has steadily declined

in North America, as has union membership.

Private sector unions are only about 10% of the

There was a strike not that long before the bankruptcy was announced. Coincidence? I think not.

And then, in a conversation with Dick Morley about

workforce, down from more than 20% some 30 years

the Internet, he made a comment about availability,

ago. The non-union jobs that rely on their union

meaning that the Internet connection he has doesn’t

brothers probably can’t be accurately counted, but I

always have to work the best, but it always should be

submit that it is a big number. And make no mis-

available, just like the PLC.

take, public sector unions are part of the problem

and solution as well.

The Globe and Mail (www.theglobeandmail.com)

So herein lies the solution to the problem: availability.

Unions and companies need to build an environment of trust and cooperation, but the fulcrum of this

in Toronto reported on Feb. 24 that South African

needs to be the function of availability and removal

mining companies are moving toward mechanized

of the disruption index.

mining to “free themselves from crippling strikes

and labor unrest.”

This is the pivot point in my estimation: the disruption index.

Why would we create more jobs that “require”

the attitude of unions to care nothing about anyone

other than themselves?

Well, allow me cross over here and say that we

should, but with conditions.

Unions are necessary beasts. Management is just

Unions and companies need to build an

environment of trust and cooperation, but

the fulcrum needs to be availability and

removal of the disruption index.

I am not a labor guru by any stretch, but if I knew

that I had the full support of my worker staff and that

they would be available, in other words no strikes,

then my contingency related to production downtime

as bad, overrun with CEOs with golden parachutes,

due to labor disruption would be removed. Also, if I

large salaries and profit margins that bulge, while

knew my customers would always be available for

insisting that the worker bees need to take a pay

my service or product, then the small-and-medium-

cut. Every department seems to have bonuses for ev-

business landscape would look very different. My

ery level of management based on profitability. For

business plan doesn’t have to have that “what if…?”

example, if it costs money to be safe, then unsafe

clause in it. I could have a long-term plan just like the

conditions are what exist.

Chinese have.

Unions have fought for a ton of good issues, but

they have to become thoughtful leaders in order to

allow manufacturing and productivity to come home.

Imagine a workplace based on trust.

China has been the beneficiary of our fall from

grace. Lack of regulation might be a big part of it, but

Take air travel in Hawaii. Additional charges of

it just seems that farming the work out to a third-

$17 per bag both ways on top of an already expen-

party makes it easier. It’s now become pretty clear

sive short-haul flight makes one wonder how that

that it isn’t a wages issue.

revenue could be spent in other areas of the econo-

Unions need to become that third-party and provide

my. Did the baggage handlers, ticketing staff, pilots

a leadership role in bringing back prosperity to the

and/or pension reform cause this massive inflation-

homeland. We, especially our industry, prosper when

ary increase in air travel?

we make things. Now that would be innovative!

We pay for things we shouldn’t have to. How can

we foster a renewed manufacturing front that’s

jeremy Pollard, CET, has been writing about technology

without an “it’s all about the money” attitude?

and software issues for many years. Pollard has been

Then I remembered vacation airline Canada 3000

and Dick Morley.

controldesign.com

CD1403_21_EMBEDDEDINTEL.indd 21

involved in control system programming and training for

more than 25 years.

March 2014 Control Design

21

3/10/14 5:08 PM

CD1403_FPA.indd 22

3/7/14 1:45 PM

CD1403_FPA.indd 23

3/7/14 1:46 PM

INDISCRETE

Sneak Preview: Hannover Fair

ONLY MOVIES OFFER coming

attractions, not industrial trade

shows, right? Wrong.

The organizers of one of the

world’s largest and most comprehensive manufacturing exhibition,

Hannover Messe (www.hannovermesse.de), presented a preview of

its upcoming 2014 edition at the

Radialsystem V hall in Berlin.

The fair will be held April 7-11 in

more than two dozen huge exhibition spaces in Hannover. However,

the preview gave attendees an

early look at some of the event’s

major innovations and exhibitors.

All were focused on its primary

COME TO THE FAIR

Detlef Zuehlke, Dutch ambassador Monique T.G. van Daalan and Jochen Koeckler

answer questions after their presentations during the Hannover Messe Preview.

“Integrated Industry—Next Steps”

theme and the specific steps

Systems (IFS) at the German

network via web servers, which

needed to bring the Smart Factory

Research Center for Artificial Intel-

are already less costly and can be

concept to life using the integrated

ligence (www.dfki.de), which has

combined like Lego blocks to form

tools of Industry 4.0, a.k.a. “The

been developing its Smart Factory

larger systems,” added Zuehlke.

Fourth Industrial Revolution,”

KL program since 2005. “Just as we

which will be driven by Internet-

have smartphones with data avail-

models of how smart factories will

connected devices.

able anywhere and anytime, and

operate, Hannover Messe’s exhibi-

we’re moving toward smart homes

tors will show many Industry 4.0

describe Hannover Messe in

and smart cars, we’re also going

tools fair visitors can use to make

a nutshell, I say it’s all about

to need smart factories,” said

their applications and facilities

competitiveness,” said Deutsche

Zuehlke. “They’ll be more flexible

smarter. For example, Zuehlke

Messe board member Dr. Jochen

and agile to handle more varied

added that one smart factory

Koeckler. “It’s about people coming

products, and have shortened

demonstration will consist of a

together to exchange ideas that

production steps, such as quicker

five-module production line for as-

will produce efficiencies, generate

setup and retooling times and

sembling business card boxes with

investments and make them more

modular components that are easy

secure RFID tags. The integrated

competitive. However, to stay

to plug and play. Smart machines

line consists of a quality assur-

competitive, manufacturers need

are going to need smart opera-

ance section by Lapp Kabel, laser

flexible, intelligent factories of the

tors, smart product designers and

engraving section by Phoenix Con-

future in which machines, plants

smart managers.”

tact, and three assembly sections

“When people ask me to

and products can talk to each

Zuehlke explained these smart

Besides presenting full-scale

by Harting and Bosch Rexroth.

other. The upcoming fair will pres-

factories will be constructed from

Each section will have smart ma-

ent the steps industry must take to

a variety of building blocks, start-

chine components to coordinate

move from its smart-factory vision

ing with cyber physical systems

tasks with the others, network via

to a real-life, integrated, Industry

(CPSs) and smart production line

TCP/IP, Wi-Fi and RJ45 protocols,

4.0 factory.”

components, which will be linked

and follow Han-modular standards

via OPC-UA and other networking

for plug-and-play connectors.

More specific steps for achiev-

Koeckler projected that Han-

ing the fair’s Integrated Industry

protocols to enterprise resource

concept were presented by Prof.

planning (ERP) systems. “Now field

nover Messe is expected to top its

Dr.-ing. Detlef Zuehlke, scientific

devices with their own Internet

last show’s results of 4,872 exhibi-

director for Innovative Factory

protocol (IP) addresses will just

tors from 69 nations.

24

Control Design March 2014

CD1403_24_31_INDISCRETE.indd 24

controldesign.com

3/11/14 6:22 PM

Tough Choice

The American Petroleum Institute created strict

motor performance and manufacturing quality

standards to ensure safe, reliable operation in

tough Petro Chemical applications. In fact, Baldor

engineers participate on the working groups that are

instrumental in establishing API 541 and 547 motor

standards. Today Baldor•Reliance® API 547 general

purpose and API 541 critical service motors are hard

at work for Petro Chemical users around the world.

Count on Baldor•Reliance API motors to make your

next tough Petro Chemical motor application an easy

choice.

baldor.com

479-646-4711

• API Certified

• Custom Built to Your Specs

• Energy Efficient

• Unmatched Quality

©2012 Baldor Electric Company

CD1403_FPA.indd 25

3/7/14 1:48 PM

INDISCRETE

Mining Gets a Really Big Wheel

BELAZ-75710, THE WORLD’S largest, mining, two-

project was completed

axle, all-wheel-drive, dump truck with weight-carrying

from ordering to com-

capacity of 450 metric tons, has demonstrated a perfor-

missioning in less than

mance worth of an entry in the Guinness Book of World

two years.

Records. The new vehicle rolled out of the BelAZ plant

BELAZ-75710 is the

in late 2013, and is being field tested as the biggest ma-

first vehicle in the

chine of its class with a record-breaking capacity.

class of super-high-

To suit the needs of the gigantic haul truck, Siemens

load trucks having

developed a unique AC traction drive system, MMT500.

a weight-carrying

The system is comprised of four 1,200-kW electric mo-

capacity of 450 tons. It

tors, two traction generators, three blowers, a brake re-

is over 20 meters long,

sistor unit and a control cabinet with two ELFA inverters.

nearly 10 meters wide

WE’RE GONNA NEED

A BIGGER GARAGE

BelAZ-75710, the world’s largest, mining,

two-axle, all-wheel-drive dump truck with

weight-carrying capacity of 450 metric

tons, is powered by a Siemens MMT500 AC

traction drive system.

The new dumper has eight wheels, each designed

and eight meters high.

for about 100 tons of load. Therefore, Siemens traction

The turning diameter

division experts chose to develop a reliable and power-

is about 20 meters. The vehicle maximum speed is 64

ful all-wheel drive train with four electrical machines.

km/h. BelAZ-75710 is in high demand in the mines of

The use of the all-wheel gear has opened up new pos-

Kuzbass region of the Russian Federation, and in certain

sibilities of distributing tractive effort to both axles.

coal strip mines of Chile and in North America. The first

Further, in case of failure of one of the driving gears, an

dump truck is due to set off for one of the open mines of

emergency mode can be activated, which would enable

Kuzbass coal field.

the dumper to get to the service station without being

Currently, Siemens also supplies BelAZ OJSC with

towed. The traction motors for the electric gear were

AC traction electric drives for 240-ton and 360-ton

manufactured at Siemens facilities in Nuremberg. The

dump trucks.

G r a p h i c H M I | P L C s | P a n e l P C s | O I Ts

Powerful Industrial HMIs

for Every Need...

4.3” to 15” Display Sizes

• High Resolution Graphics

• Serial, Ethernet, & USB

• SD & USB Expandable Storage

• Audio & Video

• Cast Aluminum Enclosure

• Quick and Easy to Program

...at a fraction of the cost

of competing brands!

Call today for a Free Demo

Every Machine

Needs the Human Touch

CD1403_24_31_INDISCRETE.indd 26

425.745.3229

3/11/14 6:23 PM

CD1403_FPA.indd 27

3/7/14 1:48 PM

INDISCRETE

Asia to Top Market for Machine-Safety Components

THE WORLD MARKET for

2014 to become the second larg-

essary expense by some. There-

discrete machine-safety com-

est regional discrete machine-

fore, simpler and cheaper safety

ponents was estimated at $3.4

safety component market.

components are still more prefer-

This market is largely driven

able in Asia. Indeed safety relays,

fi rm IHS. The American mar-

by China and the other emerging

basic interlock switches and type

ket accounted for 21% and Asia

economies in the region, which

2 light curtains are estimated to

20%. The remaining 59% of 2012

are becoming more conscious

be considerably more common

revenues were in Europe, Middle

of safety in their industrialized

than their more complex equiva-

East and Africa (EMEA).

workplaces.

lents. Safety standards are not

billion in 2012, reports research

Price pressure and a lack of

yet established in countries like

in Asia is higher than that of

safety directives means Asia can

China, but they’re on their way.

the American market, as has

be a tough market to penetrate.

It seems likely they will be based

been the case for a number of

However, influence from multi-

on European standards, which is

years. Machine-safety in Asia is

national companies, as well as

beneficial for European vendors

also playing catch-up. As such,

realization from local end users

operating in Asia. They’re less

machine-safety revenues are

that safety is linked to productiv-

likely to need to modify their

projected to grow more quickly at

ity, means more machine build-

product range. If these standards

12.4% compound annual growth

ers are using safety components

come to fruition, it will mean a

rate (CAGR) to 2017 versus 6.8%

more often, boosting their market

huge boost for the safety compo-

CAGR for the American market.

potential. Regardless of the great-

nent market in Asia.

This means that Asia is forecast

er realizations of the benefits of

to surpass the Americas during

safety, it’s still seen as an unnec-

Overall industrial growth

Safety relays offer the lowest

cost form of controlling safety

samosPRO - Programmable Safety Controller

OEM and MRO applications

Flexible and modular I/O

Online simulation and diagnostics

Function block programming

Simulation and diagnostic tools

safety

Network and gateway options

Contact Wieland for your free, fullversion programming software

Wieland Electric Inc. | 1 800 wieland (1-800-943-5263) | www.wieland-safety.com | technical.support@wieland-electric.com

Wieland - Safety - samosPRO.indd 1

CD1403_24_31_INDISCRETE.indd 28

2/18/2014 3:20:17 PM

3/12/14 4:06 PM

EPSITRON® Power Supplies...

Value + 4 Approvals

CD1403_FPA.indd 29

3/7/14 1:49 PM

INDISCRETE

5,500

16%

and, Japan aside, Asian revenues

are projected to grow more quickly

than those of configurable safety

14%

5,000

modules and safety PLCs. Japan is

a much more mature market, in

line with western regions, and so

12%

4,500

higher-end safety equipment is

more common, but, as the Japanese economy remains flat, this

10%

does not boost the market much.

Globally, safety-component

4,000

revenue growth is forecast to

8%

continue to grow above that of

industrial growth. The realiza-

3,500

6%

tion of cost savings through

integration of safety is evident.

Reducing potential for accidents

3,000

($B)

2012

2013

2014

2015

2016

4%

2017

means less downtime and injuries, which improves productivity

and reduces outlays. Overall, the

IHS

Revenues ($M)

EMEA

Americas

future is strong for safety compo-

Asia Pacific

©2014 IHS

nents, and Asia is proving to be a

large potential market.

CAST STAINLESS STEEL

NE

W

XCESX

ENCLOSURES

Ideal for offshore applications in oil & gas industry

5 standard sizes available up to 24”W x 36”H x 10”D

Rated for Division 1 and Zone 1 Hazardous Areas

Corrosion resistant, cast stainless steel 316L

UL, cUL, ATEX, and IECEx Certifications

Flat plate cover design

BUILT TO LAST

IN HIGHLY

CORROSIVE AREAS

Call for a Free Application Evaluation!

TM

OWN YOUR ENVIRONMENT.

adalet.com • info@adalet.com • TEL 216.267.9000 • FAX 216.267.1681

CD1403_24_31_INDISCRETE.indd 30

3/11/14 6:23 PM

Autodesk to Accelerate

Design-Led Revolution

AUTODESK (www.autodesk.com)

the software and training to cre-

has launched the Autodesk Foun-

ate solutions that address these

dation, which will invest in and

challenges.

support the nonprofit organiza-

One of the program’s fi rst

tions using the power of design

grantees is KickStart Interna-

to help solve epic challenges.

tional. KickStart designs simple

In partnership with the com-

agricultural irrigation tools that

pany, Autodesk Foundation will

help African farmers start profit-

provide select design-oriented

able businesses and rise out of

grantees with software, training

poverty. Others include Mass De-

and fi nancial support.

sign Group, which designs health

Impact design focuses on gen-

facilities in parts of the world

erating significant, measurable

where they’re needed most; D-

progress toward solving to-

Rev, which designs and develops

day’s epic challenges—access to

devices and products to improve

healthcare and education, clean

the health and income of people

energy and water, efficient trans-

living on less than $4 a day; and

portation and others. Through

the Rural Studio at Auburn Uni-

the foundation’s Impact Design

versity, which has a 20K House

Program, carefully selected non-

program that challenges students

profits will receive funding and,

to design energy-efficient homes

in partnership with Autodesk,

that can be built for $20,000.

MERGERS, ACQUISITIONS AND ALLIANCES

The MTConnect Institute (www.mtconnect.org) and the National

Center for Defense Manufacturing and Machining (ncdmm.org) announced a memorandum of understanding to establish a cooperative

forum resulting in collaboration between the two organizations to

continue defining, developing and securing programs aimed at furthering the MTConnect standard. The MTConnect Institute develops

and provides open standards intended to foster greater interoperability between manufacturing controls, devices and software applications by publishing data over networks using the Internet protocol.

NCDMM fosters collaboration between government, industrial and

academic organizations to promote the implementation of best practices to key stakeholders through the development and delivery of

disciplined training, advanced technologies and methodologies.

Sierra Wireless (www.sierrawireless.com) signed an agreement

with Tech Mahindra (www.techmahindra.com) to provide turnkey

M2M solutions globally. The collaboration leverages Sierra Wireless

device-to-cloud offerings and Tech Mahindra’s system integration

and application development expertise to offer turnkey solutions

tailored for prospective M2M customers in markets such as energy,

transportation, industrial and healthcare.

controldesign.com

CD1403_24_31_INDISCRETE.indd 31

March 2014 Control Design

31

3/11/14 6:24 PM

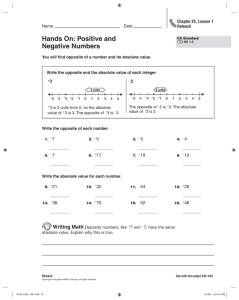

Despite differences in their approach to problem-solving,

older and younger engineers begin to appreciate each

others’ skill sets and methods

by Sarah Cechowski, associate editor, digital media

T

hese kids today. Do they really address engineering problem-solving

in radically different manner than their older peers? Has the Internet

caused some disharmony between the generations that inhibits their working together? Yes and no.

The Control Design 2014 product research and buying habits survey

results, combined with discussions with machine builders and system

integrators, suggest a more nuanced picture. In fact, they suggest that the

“millennial gap”—the differences in the way each generation approaches the

same job—is beginning to narrow.

While there still are age-group-specific differences in how newer and

more seasoned engineers relate to social media and digital access, industry

veterans and recent graduates are becoming codependent on one another.

As these veterans learn to adapt to new technology and web tools that

recent graduates grew up reliant on, younger professionals are learning to

appreciate the knowledge of the older generations.

It’s a Wonderful Web

Machine builders and system integrators say technology has significantly impacted the way they research products, find solutions to on-the-job

problems and stay connected to other professionals.

The survey results show that 33% of respondents say searching a supplier’s website is their most used method for researching and specifying

CD1403_32_39_COVERSTORY.indd 32

3/11/14 5:57 PM

automation and controls, while 24% mostly meet or

help answer questions. But if they’re unable to solve the

speak directly with their automation suppliers’ techni-

problem, his next go-to is to search Google.

cal engineers or product managers. Eighteen percent say

Forums such as MrPLC.com are great for getting an-

they mostly meet or speak with local distributors; 12%

swers from vendors because often the vendor’s technical

search independent, non-vendor websites; 7% read trade

support staff are on them giving feedback on product

magazines; and only 6% visit suppliers at tradeshows.

issues, says Stevic. Online resources like these are much

Somewhat surprisingly, user group conferences were not

more efficient than calling the vendor and “playing ring

valued as a product research tool.

around the keypad on your phone,” he adds.

PDFs are one of the biggest and simplest changes

But Jonathan Hoagland, senior applications engineer

with respect to technology advances, says Steven

for Parker Electromechanical (www.parkermotion.com),

Fage, founder and principal at 5 Nines Automation

disagrees with Stevic. He believes the phone is still the

(www.5ninesautomation.com). In 2007, it still was all

lifeline for his customers to diagnose problems, and it’s

about the catalog, he says. No one went to the Internet to

become easier than ever before. For example, Smith says

learn about the respective product.

if he doesn’t have direct business with Rockwell Auto-

Now everyone asks for a colorful PDF of the product, a

mation, he’s unable to contact the company’s technical

YouTube video or the website on which it can be found.

support because he’s not an authorized user. But he can

“Oftentimes, customers have done their research before

connect with people who work for the company or are

we even get there,” Fage says. “When we go there with a

connected to them through LinkedIn to get the informa-

catalog they say ‘Sure, I guess I’ll take it,’ and it’s usually

tion he’s looking for about their products.

the older guys. I’d say the biggest change is they usually

Social media networks such as LinkedIn open up op-

know more about your product and the competition than

portunities to connect with professionals with similar

you do, because they’ve done their research.”

interests, says Kailash Mariappan, senior automation en-

Tom Kvech, systems engineer for high-speed saw

gineer at manufacturer Saint-Gobain (www.saint-gobain.

manufacturer Metlsaw Systems (www.metlsaw.com),

com). Mariappan was looking for answers on LinkedIn

adds, “We’d have to put in a request and then get the

about using an iPad for automation. “I found a guy who

physical hard copy of the product brochure, or we’d have

lives in Spain, and he gave me insight into mobile appli-

to have a catalog sent to us. By the time we got [the cata-

cations for automation,” he says. “It’s really amazing how

log], it was out of date. Now we download the latest PDF.

social media is changing the professional world.”

You can search for that product online and have the most

up-to-date information.”

In the past, you could get product help only by con-

Facebook too has been an excellent way to stay connected, says Phil Laurette, controls design engineer

for industrial automation system integrator Outbound

tacting vendor support directly or by asking people at

Technologies (www.outboundtech.com). While he uses

your company, says Jason Cleveland, controls engi-

LinkedIn predominantly for professional relationships

neering manager for turnkey solutions and material

and Facebook for personal ones, over time, those lines

handling systems designer Laidig (www.laidig.com).

have become blurred, and many of his professional rela-

Now the Internet has become an avenue for researching

tionships have become personal ones as well.

a particular problem, with search engines spitting out a

“There now are quite a number of engineers that I’ve

ton of URLs where you can find people all over the world

known for 15 or more years that I stay connected to on a

asking the same question.

regular or semi-regular basis,” Laurette says. “In the past,

“[In the past] it was a whole lot of phone calls, tech

I was not able to stay as connected to former colleagues,

support and searching through hard copy manuals,”

and often they fell off the face of the earth when we

says David Smith, systems designer for Johnson Controls

stopped working together. But that’s no longer the case.”

(www.johnsoncontrols.com). “Now I can take a problem

and search Google, Wikipedia or online forums. Rather

Who Uses What for Research

than look at a hard copy manual, if I’ve got a soft copy, I

When asked what types of content listed in search

can just search through the PDF. It saves a lot of time.”

engine results they prefer to view when doing product

Thomas Stevic, controls engineer for PLC and mo-

research, only two categories elicited a substantial fol-

tion control solutions provider, Cincinnati Integration

lowing. Some 81% of survey respondents look to techni-

& Automation (www.cincyintegration.com), says when

cal articles and whitepapers, and 70% said online articles

he first started, his intial point of contact would be the

from publications and news sources were worthwhile.

vendor because most have a technical support staff to

Only 36% value looking at images; 32% prefer YouTube

controldesign.com

CD1403_32_39_COVERSTORY.indd 33

March 2014 Control Design

33

3/11/14 5:58 PM

videos; 31% noted online forums;

new products in electronic design.

Fage, on the other hand, finds

and 12% pointed to blogs.

people will literally have a video

capture of their desktop showing you

white papers difficult to dig

exactly how to go through a specific

there’s really no specific site,” Kvech

through for product research. The

configuration process or program-

says. “There’s no aggregator like

bibles for the plastics industry are

ming procedure,” he says.

there is with other types of indus-

Plastics News and Plastics Today.

tries.” Kvech uses a number of digital

However, Fage says one of the big-

onstrations to help educate industry

trade journals including Control

gest and most up-and-coming tools

professionals. He develops videos

Design, Rockwell Automation’s The

available on the web is YouTube

to train new engineers or creates

Journal and Modern Metals to stay up

because its users can see how a

refresher courses for experienced

to date on the latest products and

process works.

engineers. Two of his most recent

“In the industry, my feeling is

“This is huge because my back-

industry trends.

Hoagland records and posts dem-

videos were on motion control ba-

ground is in automation, and now

sics and programming an ACR9000

tronics maintenance technician for

I’m getting into the plastics process-

controller, and how to create a cus-

weighing systems specialist Comer-

ing side of the business,” he says.

tom servomotor file for Compax3.

cial Such (www.comercialsuch.com),

“Injection molding, extrusion, blow

While Stevic has watched some

reads Vision Systems and Electronic

molding, thermo forming—there are

YouTube videos for his job, he finds

Design to research the latest indus-

so many different processes. If I want

them very non-specific to the subject

try technology. He also watches

new customers, I need to be able to

matter he looks for. If things were

webinars and videos, and receives

understand their process before I can

broken down into much small pieces,

whitepapers from Engineering TV on

help them in their businesses.”

videos would be more helpful, he says.

Tomas Moruno, industrial elec-

The things he looks for in a quality

DEMOGRAPHICS

Respondent industries

Assembly

5%

Electronics pick and place

2%

Material handling/

transport systems

6%

Metalworking

11%

One-off, custom

“For example, I set up a VFD

video include what the technology

[variable-frequency drive] to use

looks like and what the process looks

a DeviceNet card,” he explains. “I

like. Looking at an image or reading

looked through the book and, of

a technical paper does not offer the

course, the book covers everything.

same benefits that video does.

I called the technical people at the

Smith says he watched a recent

factory, but they can’t really show

Microsoft SQL Query about configu-

you what you’re doing. If there were

ration on YouTube that gave him a

a two-minute video on what buttons

step-by-step, how-to breakdown.

to push and which things to select for

17%

“Rather than following through a

setting up a drive on DeviceNet, that

Packaging

4%

thread on how to do something,

would have been wonderful.”

Paper industry

1%

Printing and converting

2%

THE SEARCH FOR A WELL-TUNED ENGINE

Rolling mills

1%

Technical search using global search engines

Semiconductor tools

1%

System integration

24%

Woodworking

1%

Other

24%

Job function

Control system design/

engineering

55%

Company management

14%

Tech support

9%

Research/development

11%

Other

11%

Responses from 250+ study participants

34

Control Design March 2014

CD1403_32_39_COVERSTORY.indd 34

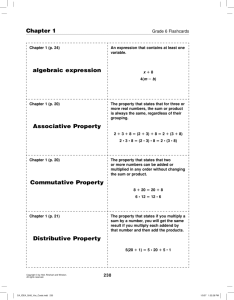

You agree or strongly agree that:

‘14

‘13

‘12

‘11

‘10

‘09

The first page (or more) of results

contains well-focused hits

77%

80%

79%

78%

76%

82%

Too many results are biased, vendor

product plugs

73%

72%

67%

61%

70%

69%

Too many results are outdated

54%

52%

45%

47%

52%

51%

Too many results have nothing to do

with what I’m looking for

66%

69%

71%

70%

75%

73%

It’s a pain to sift through the results,

but at this point there’s no better

web-based research tool for me

76%

73%

77%

74%

73%

76%

I’ve gotten better at search

strategies and techniques, and

that has helped get better results

93%

89%

88%

90%

N/A

N/A

controldesign.com

3/11/14 5:58 PM

Consistent Spot Size

Repeatable Alignment

OLED Graphic Display

180° Rotating Connector

NPN and PNP Outputs

10-30VDC

IP 68

240 Microseconds

Response Time

www.ttco.com/smartdot.aspx

CD1403_FPA.indd 35

3/7/14 1:49 PM

Reliable Resources

within the company,” she says. “It helps me with what

When asked what resources they turn to when they

I need to think about when I want to pitch an idea and

look for answers to a technical problem, 78% of survey

how that will affect the company. ‘System-level’ thinking

respondents indicated they still prefer to meet or speak

is something I am really trying to develop.”

directly with their automation suppliers; 61% read

Other machine builders and system integrators in-

online articles; 41% read online forums; 17% read blogs

dicate using forums such as PLCtalk (www.plctalk.net),

and 9% use LinkedIn groups.

PLCS.net (www.plcs.net), MrPLC.com (www.mrplc.com)

Andy Milluzzi, 2012 Rose-Hulman Institute of Technol-

and Rockwell Automation’s Knowledge Base (www.rock-

ogy graduate and now research assistant at the National

wellautomation.com/knowledgebase) for FactoryTalk for

Science Foundation’s (NSF) Center for High-Performance

answers to on-the-job problems.

Reconfigurable Computing (CHREC, www.chrec.org) at

Fage says LinkedIn is making a huge impact in the

the University of Florida, follows blogs from Intel (www.

automation community through “groups,” which func-

intel.com), Texas Instruments (TI, www.ti.com), Mat-

tion similar to forums. Conducting his own research,

Lab (www.mathworks.com/products/matlab) and Make

Fage found various surveys that said LinkedIn is the

(makezine.com), a hybrid magazine/book devoted to do-

most heavily used social media channel in the plas-

it-yourself (DIY) technology projects.

tics industry. Fage discovered LinkedIn groups such as

Milluzzi also reads forums hosted by TI, National