Lecture 2 : Capillary Rheometry Corrections

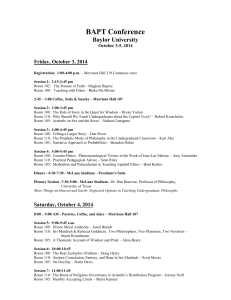

advertisement

CM4655 Morrison Lecture 2 2014 CM4655 Polymer Rheology Lab entrance region Shear Viscosity Measurement in a Capillary Rheometer r z 2R well-developed flow Prof. Faith A. Morrison Michigan Technological University exit region 1 © Faith A. Morrison, Michigan Tech U. Shear Rheometry Goal: Measure the viscosity of a very viscous, non-Newtonian fluid. Difficulty: Because we do not know the rheological behavior of our sample (whether it is Newtonian, power-law, etc.) we do not know how it will behave. If we do not know how it will behave, it is difficult to design an experiment to measure its behavior (Catch 22). Strategy: Design experiments making the fewest assumptions possible so that the design is applicable to all (most) fluids. Begin with: What is the definition of viscosity? 2 © Faith A. Morrison, Michigan Tech U. 1 CM4655 Morrison Lecture 2 2014 By definition, viscosity is measured in pure, homogeneous shear flow force=F velocity field shear rate: v1 ( H ) V 0 H 0 0 constant v1 ( x2 ) H x2 0 x2 v 0 0 123 x1 x1 (t t ) x1 (t ) v1 x2 V x2 x1 path lines 21 F / A 0 V / H 3 © Faith A. Morrison, Michigan Tech U. By definition, viscosity is measured in pure, homogeneous shear flow Means, the shear rate force=F is the same at every v1 ( H ) V 0 H position in space velocity field shear rate: 0 constant v1 ( x2 ) H x2 x1 x1 (t ) 0 x1 (t t ) V v1 x2 0 x2 v 0 0 123 x2 x1 path lines 21 F / A 0 V / H 4 © Faith A. Morrison, Michigan Tech U. 2 CM4655 Morrison Lecture 2 2014 By definition, viscosity is measured in pure, homogeneous shear flow Means, the shear rate force=F is the same at every v1 ( H ) V 0 H position in space velocity field shear rate: 0 0 constant has v1 ( xThis x2 2) the advantage of subjecting every x1 fluid particle to the same deformation x (t t ) H x1 (t ) v1 x2 0 x2 v 0 0 123 1 V x2 x1 path lines 21 F / A 0 V / H 5 © Faith A. Morrison, Michigan Tech U. By definition, viscosity is measured in pure, homogeneous shear flow Means, the shear rate force=F is the same at every v1 ( H ) V 0 H position in space velocity field shear rate: 0 constant H the advantage of subjecting every x1 fluid particle to the same deformation x (t t ) has v1 ( xThis x2 2) x1 (t ) 1 x2 v1 x2 0 x2 v 0 0 V 123 (just in case it matters to the measurement of viscosity) x1 path lines 0 21 F / A 0 V / H 6 © Faith A. Morrison, Michigan Tech U. 3 CM4655 Morrison Lecture 2 2014 By definition, viscosity is measured in pure, homogeneous shear flow Means, the shear rate force=F is the same at every v1 ( H ) V 0 H position in space velocity field shear rate: 0 0 constant has v1 ( xThis x2 2) the advantage of subjecting every x1 fluid particle to the same deformation x (t t ) H x1 (t ) 1 x2 v1 x2 0 x2 v 0 0 V 123 (just in case it matters to the measurement of viscosity) x1 (which it does, for non-Newtonian fluids) path lines 7 © Faith A. Morrison, Michigan Tech U. By definition, viscosity is measured in pure, homogeneous shear flow force=F velocity field shear rate: v1 ( H ) V 0 H 0 0 constant v1 ( x2 ) H x2 x1 x1 (t ) x1 (t t ) V v1 x2 0 x2 v 0 0 123 x2 x1 path lines 21 F / A 0 V / H 8 © Faith A. Morrison, Michigan Tech U. 4 CM4655 Morrison Lecture 2 2014 Drawbacks •Parallel plate flow is difficult to produce (maintaining constant gap for example) •Stress measurements are affected by edge effects and spacers used to maintain gap •Signal can be low amplitude (signal-to-noise ratio) •Sample loading is inconvenient and complex Even though producing the parallel plate geometry is tricky, it has been done: J. M. Dealy and S. S. Soong J. Rheol. 28, 355 (1984); doi:10.1122/1.549756 A Parallel Plate Melt Rheometer Incorporating a Shear Stress Transducer Can we use an alternate, easier geometry? (Sliding Plate Rheometer) 9 © Faith A. Morrison, Michigan Tech U. Sliding Plate Rheometer Image from: www.rheology.org Image from: www.mcgill.ca/photos/2006/february/ John Dealy McGill University Hee Eon Park, works on a high-pressure sliding plate rheometer, the only instrument of its kind in the world. Even though producing the parallel plate geometry is tricky, it has been done: J. M. Dealy and S. S. Soong J. Rheol. 28, 355 (1984); doi:10.1122/1.549756 A Parallel Plate Melt Rheometer Incorporating a Shear Stress Transducer (Sliding Plate Rheometer) 10 © Faith A. Morrison, Michigan Tech U. 5 CM4655 Morrison Lecture 2 2014 Shear is fundamentally a sliding flow We can infer a viscosity from any sliding flow if we can relate the data back to homogeneous shear flow x2 Cartesian geometry (parallel plates) x1 Cylindrical geometry r z R r1 Telescoping sliding flow r2 r3 (capillary flow) 11 © Faith A. Morrison, Michigan Tech U. Strategy: Use capillary flow experiments (pressure drop versus flow rate) to infer viscosity Implications: •The flow is not the simple shear flow assumed when viscosity was defined; •We need to analyze the flow with as few assumptions as possible; •We need to design the apparatus to conform to the assumptions we make; •When our assumptions are only approximately satisfied, we must correct the data where possible. 12 © Faith A. Morrison, Michigan Tech U. 6 CM4655 Morrison Lecture 2 2014 Capillary Rheometer •Shear viscosity is the most widely measured rheological property •For high shear rates, the capillary rheometer is the most effective instrument for measuring shear viscosity. •The capillary rheometer does not produce pure, homogeneous shear flow, however. •Various corrections are necessary in order to turn pressure-drop/flow-rate data from a capillary rheometer into viscosity. ( ) 21 Three corrections: 1. Entrance/exit pressure loss 2. Slip at the wall 3. Non-parabolic velocity profile 13 © Faith A. Morrison, Michigan Tech U. Capillary Rheometer piston The basics F entrance region A barrel 2Rb polymer melt reservoir r z 2R well-developed flow B exit region Q 14 © Faith A. Morrison, Michigan Tech U. 7 CM4655 Morrison Lecture 2 2014 Goettfert Rheo-Tester 1000 15 © Faith A. Morrison, Michigan Tech U. Classic Newtonian flow problem: Pressure-driven flow of a fluid in a tube •steady state •well developed •long tube (no z-dependence) •no-slip at the wall For all fluids: Stress at the wall: R Definition of viscosity: cross-section A: r 4Q R3 R P0 z PR 2L For Newtonian fluids only: Shear rate at the wall: r z A L vz(r) fluid R PL 16 © Faith A. Morrison, Michigan Tech U. 8 CM4655 Morrison Lecture 2 2014 Newtonian Fluid: Hagen-Poiseuille law R 4 P Q 8L 4Q 1 PR 3 R 2 L PR 4Q 3 2L R PR 2L This is only true for Newtonian fluids. 4Q R 3 17 © Faith A. Morrison, Michigan Tech U. Corrections to Capillary flow • entrance and exit effects - Bagley correction (correct the pressure drop) •slip at the wall - Mooney analysis (correct the flow rate) (NOTE: we do not do this correction in CM4655) •Non-parabolic velocity profile - WeissenbergRabinowitsch correction (correct the shear rate at the wall; non-Newtonian effects) 18 © Faith A. Morrison, Michigan Tech U. 9 CM4655 Morrison Lecture 2 2014 Entrance and exit effects - Bagley correction The pressure gradient is not accurately represented by the raw p/L entrance region r z 2R well-developed flow P(z) p L raw exit region p L corrected z=L z=0 z 19 © Faith A. Morrison, Michigan Tech U. Entrance and exit effects - Bagley correction L PR R P 2 R 0 2L R no intercept r z Constant at fixeda Run for different length capillaries Straight line through origin with slope of 2R: P 2 R L R entrance region 2R well-developed flow exit region This is the result when the end effects are negligible. 20 © Faith A. Morrison, Michigan Tech U. 10 CM4655 Morrison Lecture 2 2014 Entrance and exit effects - Bagley correction Procedure: •For a standard set of apparent shear rates 4Q/R3, measure P in capillaries of different L/R (usually different lengths) P 2 R L R •Plot results and infer corrected shear stress from slope P 2 R L R 21 © Faith A. Morrison, Michigan Tech U. Bagley Plot 1200 effects apparent a R shear rate 4Q 3 250 Pressure drop (psi) Pend f (Q) f (a ) a ( s 1 ) 1000 120 90 800 60 40 600 400 200 Pend effects 250 s 1 a 0 -10 0 10 20 30 40 L/R -1 e(250, s ) Figure 10.8, p. 394 Bagley, PE 22 © Faith A. Morrison, Michigan Tech U. 11 CM4655 Morrison Lecture 2 2014 1200 y = 32.705x + 163.53 R2 = 0.9987 Steady State Pressure, 1000 y = 22.98x + 107.72 R2 = 0.9997 800 y = 20.172x + 85.311 R2 = 0.9998 600 y = 16.371x + 66.018 R2 = 0.9998 400 y = 13.502x + 36.81 R2 = 1 200 The intercepts are equal to the entrance pressure losses. 0 0 10 20 30 40 L/R 23 Figure 10.8, p. 394 Bagley, PE © Faith A. Morrison, Michigan Tech U. Figure 10.8, p. 394 Bagley, PE 1200 y = 32.705x + 163.53 R2 = 0.9987 Steady State Pressure, 1000 y = 22.98x + 107.72 R2 = 0.9997 800 y = 20.172x + 85.311 R2 = 0.9998 600 y = 16.371x + 66.018 R2 = 0.9998 400 y = 13.502x + 36.81 R2 = 1 200 0 0 10 20 30 L/R rz pR 2L L p 2 rz R The slopes are equal to twice 40 the shear stress for the various apparent shear rates 24 © Faith A. Morrison, Michigan Tech U. 12 CM4655 Morrison Lecture 2 2014 The data so far: Δ gammdotA deltPent (1/s) psi 250 163.53 120 107.72 90 85.311 60 66.018 40 36.81 slope psi 32.705 22.98 20.172 16.371 13.502 sh stress psi 16.3525 11.49 10.086 8.1855 6.751 sh stress Pa 1.1275E+05 7.9220E+04 6.9540E+04 5.6437E+04 4.6546E+04 Now, correct shear rate for slip at the wall 25 Figure 10.8, p. 394 Bagley, PE © Faith A. Morrison, Michigan Tech U. Slip at the wall - Mooney analysis Slip at the wall reduces the shear rate near the wall. v1 ( x2 ) v1 ( x2 ) no slip x2 x1 dv1 dx 2 dv1 dx 2 slip v1, slip x2 x1 dv1 , smaller dx 2 dv1 dx 2 26 © Faith A. Morrison, Michigan Tech U. 13 CM4655 Morrison Lecture 2 2014 Slip at the wall - Mooney analysis Slip at the wall reduces the shear rate near the wall. a 4Q 4v z ,av R 3 R without slip 4 vz ,av vz ,slip R 4v z , slip 4v z ,av R R 1 4v z , slip a , slip corrected R a ,slip corrected 4v z ,av R 4v z ,av R 4Qmeasured R 3 slope with slip Need capillaries of various radii intercept 27 © Faith A. Morrison, Michigan Tech U. Slip at the wall - Mooney analysis 800 pR , MPa 2L 4Q R 600 0.35 0.3 4v z , slip 3 0.25 0.2 -1 (s ) 0.14 400 0.1 0.05 0.01 200 0 0 Figure 10.10, p. 396 Ramamurthy, LLDPE 1 2 3 1/R (1/mm) 4 Now, correct shear rate for non-parabolic velocity profile. 28 © Faith A. Morrison, Michigan Tech U. 14 CM4655 Morrison Lecture 2 2014 For an unknown, non-Newtonian fluid, we need to take special steps to determine the wall shear rate The wall shear rate is generally greater for a nonNewtonian fluid than for a Newtonian fluid. vz(r) R ,non Newtonian Newtonian velocity profile non-Newtonian velocity profile R, Newtonian r 29 © Faith A. Morrison, Michigan Tech U. Weissenberg-Rabinowitsch correction R ( R ) 4Q R 3 1 d ln a 3 4 d ln R 10 a slope is a function of R 4Q R Sometimes the WR correction varies from point-to-point; sometimes it is a constant that applies to all data points. 3 1 slope d ln a d log R 0.1 0.1 1 PR R 2L 10 Procedure: fit a line to data, differentiate it; evaluate derivative function at points of interest. 30 © Faith A. Morrison, Michigan Tech U. 15 CM4655 Morrison Lecture 2 2014 Weissenberg-Rabinowitsch correction ln(apparent shear rate, 1/s) 7 For these data, the derivative is a constant. y = 2.0677x - 18.537 R2 = 0.9998 6 5 This slope is usually >1 d ln a 2.0677 d ln R 4 3 10 10.4 Figure 10.8, p. 394 Bagley, PE 10.8 11.2 11.6 12 ln(shear stress, Pa) 31 © Faith A. Morrison, Michigan Tech U. The data corrected for entrance/exit and nonparabolic velocity profile: R R Δ deltPent Δ sh stress gammdotA deltPent ln(sh st) ln(gda) WR gam-dotR viscosity (1/s) psi Pa Pa correction 1/s Pa s 250 163.53 1.1275E+06 1.1275E+05 11.63289389 5.521460918 2.0677 316.73125 3.5597E+02 120 107.72 7.4270E+05 7.9220E+04 11.2799902 4.787491743 2.0677 152.031 5.2108E+02 90 85.311 5.8820E+05 6.9540E+04 11.14966143 4.49980967 2.0677 114.02325 6.0988E+02 60 66.018 4.5518E+05 5.6437E+04 10.9408774 4.094344562 2.0677 76.0155 7.4244E+02 40 36.81 2.5380E+05 4.6546E+04 10.74820375 3.688879454 2.0677 50.677 9.1849E+02 Now, plot viscosity versus wall-shear-rate Figure 10.8, p. 394 Bagley, PE 32 © Faith A. Morrison, Michigan Tech U. 16 CM4655 Morrison Lecture 2 2014 Viscosity of polyethylene from Bagley’s data 1.0E+04 R R Viscosity, Pa s 1.0E+03 1.0E+02 10 Figure 10.8, p. 394 Bagley, PE R 100 Shear rate, 1/s 1000 33 © Faith A. Morrison, Michigan Tech U. Viscosity from Capillary Experiments, Summary: 1. Take data of pressure-drop versus flow rate for capillaries of various lengths; perform Bagley correction (entrance pressure) 3. Perform the WeissenbergRabinowitsch correction (wall shear rate) 4. Plot true viscosity versus true wall shear rate P(Q) final data: R / R 1.0E+04 R R Viscosity, Pa s 2. If slip is an issue, take data for capillaries of different radii; perform Mooney correction (slip) raw data: 1.0E+03 1.0E+02 10 5. Fit to a power-law to obtain model parameters if desired. R 100 Shear rate, 1/s 1000 34 © Faith A. Morrison, Michigan Tech U. 17 CM4655 Morrison Lecture 2 2014 Capillary Rheometer Measurement Procedure •Choose range of apparent shear rates and capillary sizes to allow for desired corrections. •Conduct experiments: load reservoir; push polymer through capillary with piston •Measure pressure at top of capillary at the base of the barrel (correct for entrance and exit losses); obtain wall shear stress. •Measure piston speed (convert to flow rate, correct for slip); obtain apparent shear rate. •Plot apparent shear rate versus wall shear stress; obtain WR correction •Correct apparent shear rate for non-parabolic velocity profile (non-Newtonian) •Calculate true non-Newtonian viscosity from stress/shear rate. 35 © Faith A. Morrison, Michigan Tech U. Schedule your lab time with our TA Week 4 Week 5 • First, one hour to play with the software • Second, 3 hours to take data • Third, 3 hours to take remaining data • Fourth (optional) more data 36 © Faith A. Morrison, Michigan Tech U. 18